Substrate processing apparatus and substrate placing table

A technology of substrate processing device and mounting table, which is applied to gaseous chemical plating, coating, electrical components, etc., can solve the problems of influence of film formation characteristics, low temperature, non-uniformity, etc., so as to improve temperature controllability and restrain temperature rise , to achieve the effect of film forming characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] Hereinafter, preferred embodiments of the present invention will be described with reference to the drawings.

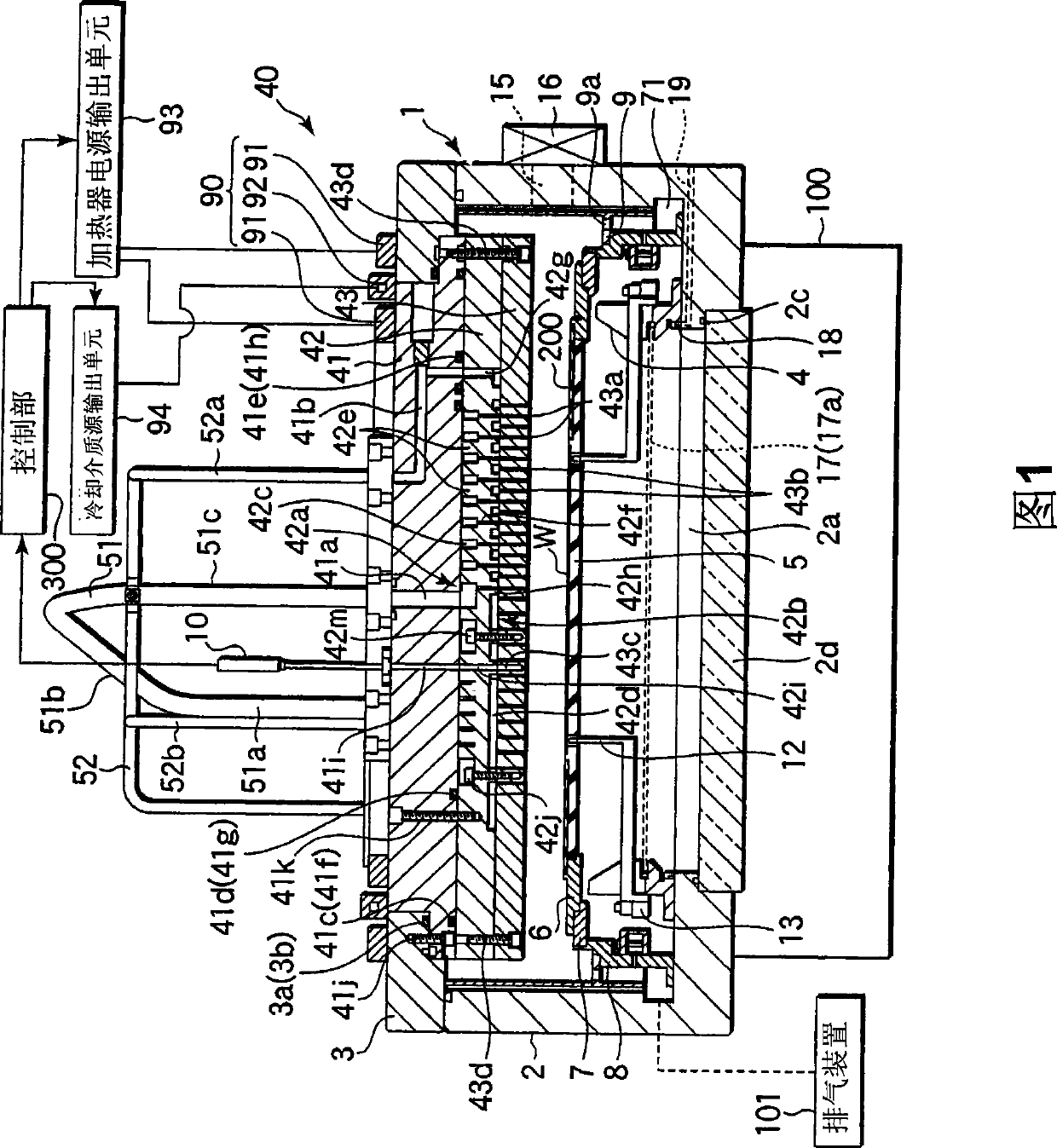

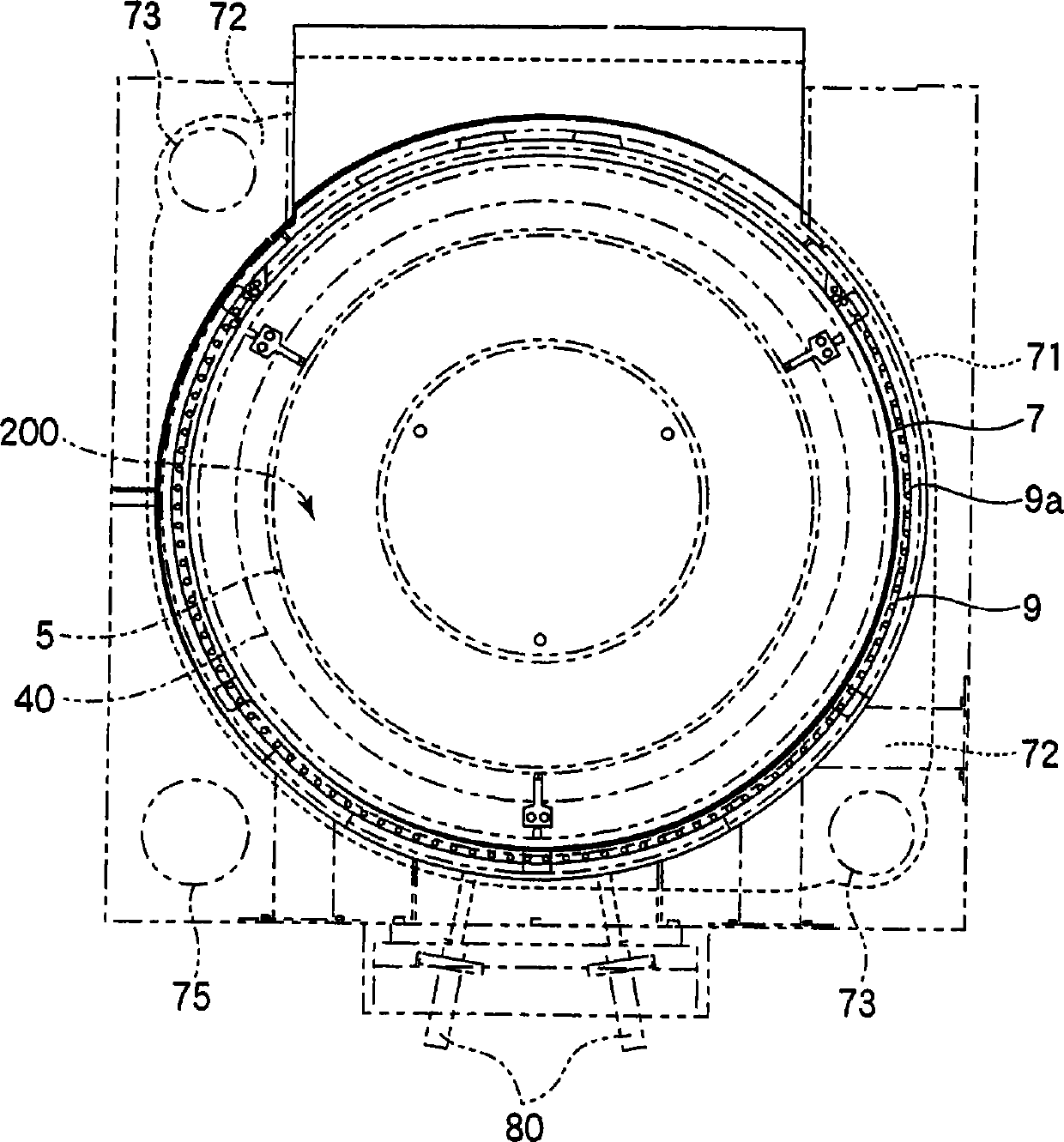

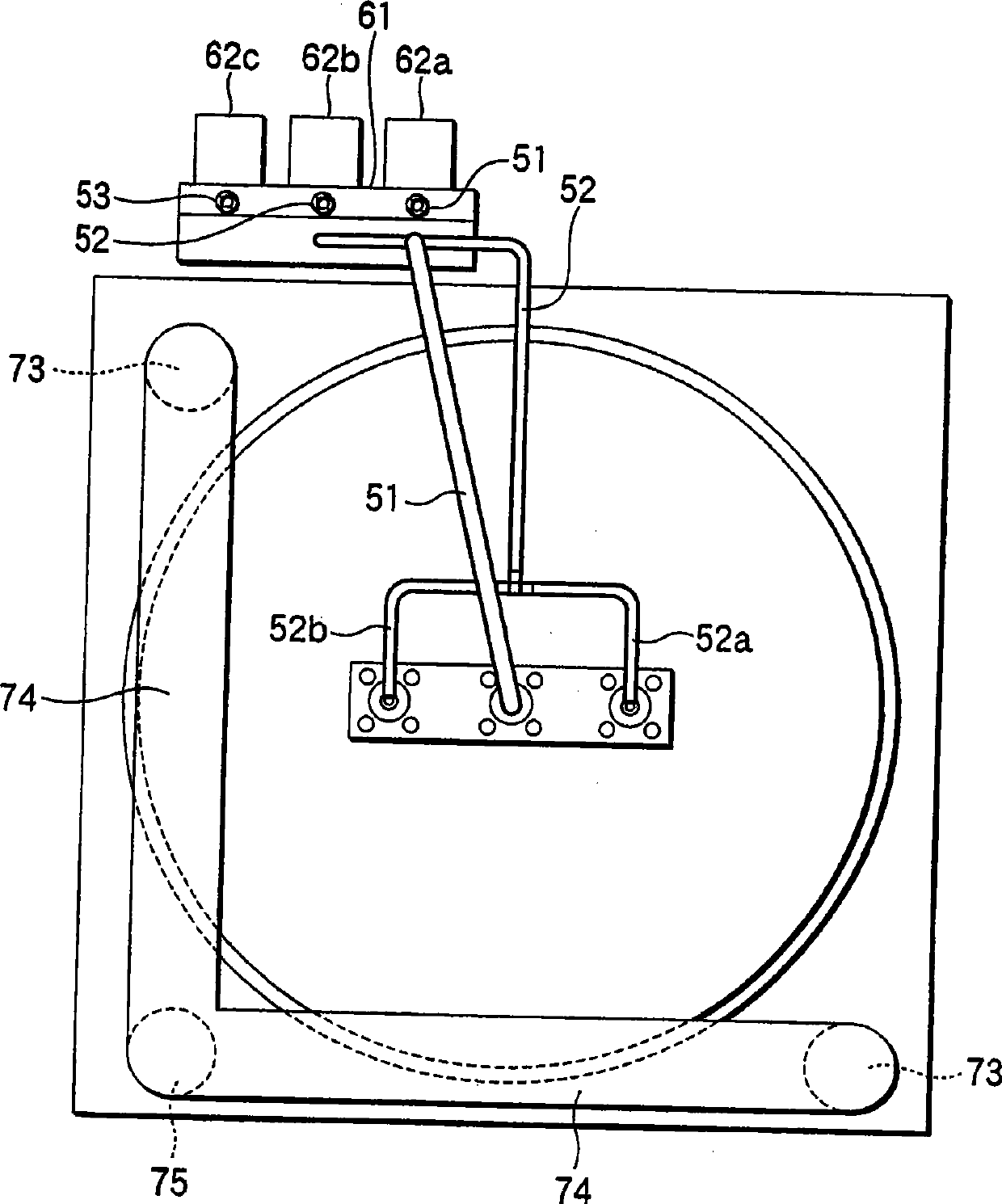

[0053] 1 is a cross-sectional view showing a film forming apparatus according to an embodiment of a substrate processing apparatus of the present invention, figure 2 is a plan view showing the internal structure of the housing of the film forming apparatus, image 3 is its top plan. Figure 4 ˜ FIG. 11 are schematic views showing components of a shower head constituting the film forming apparatus. Among them, in Fig. 1, the cross-section of the shower head represents the Figure 6 The cross section of the line X-X is asymmetrical with respect to the central part.

[0054] As shown in FIG. 1 , the film forming apparatus has a frame 1 made of, for example, aluminum or the like and has a substantially rectangular planar section, and the inside of the frame 1 is a bottomed cylindrical processing container 2 . An opening 2a for connecting the lamp unit 100 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com