Electric screw press

An electric screw and press technology, applied in forging presses, forging presses, forging/pressing/hammer devices, etc., to achieve the effect of reducing power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

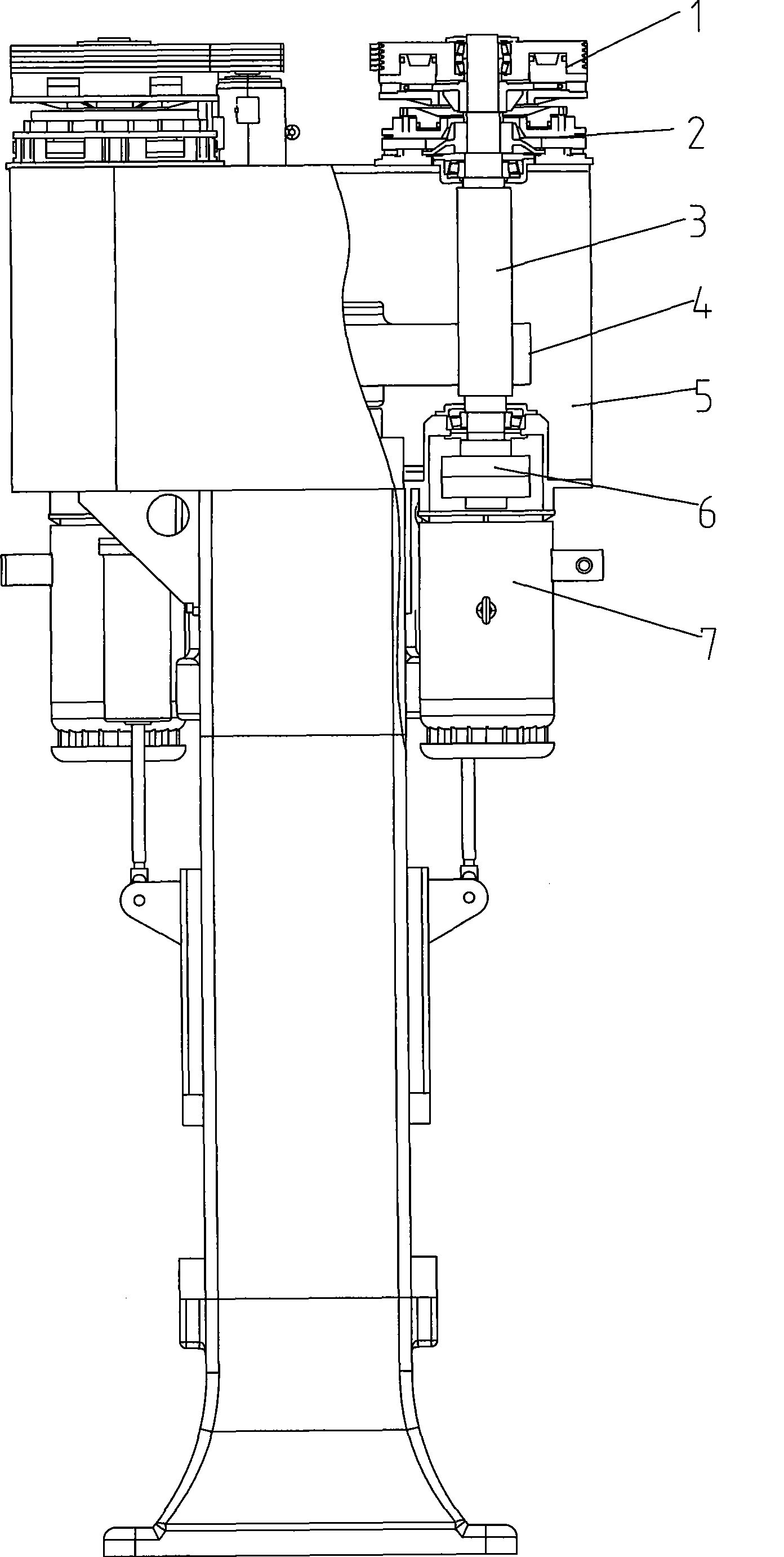

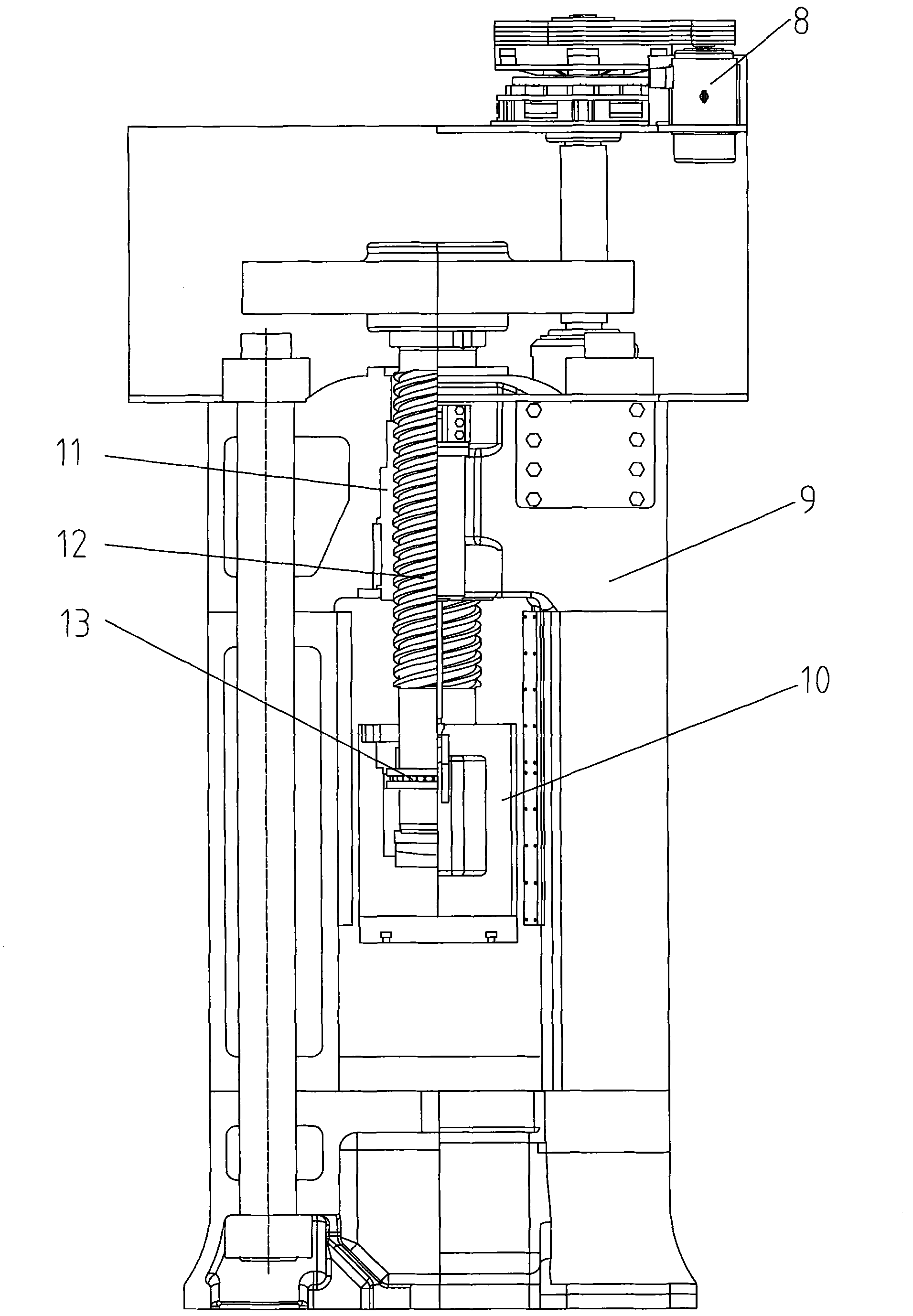

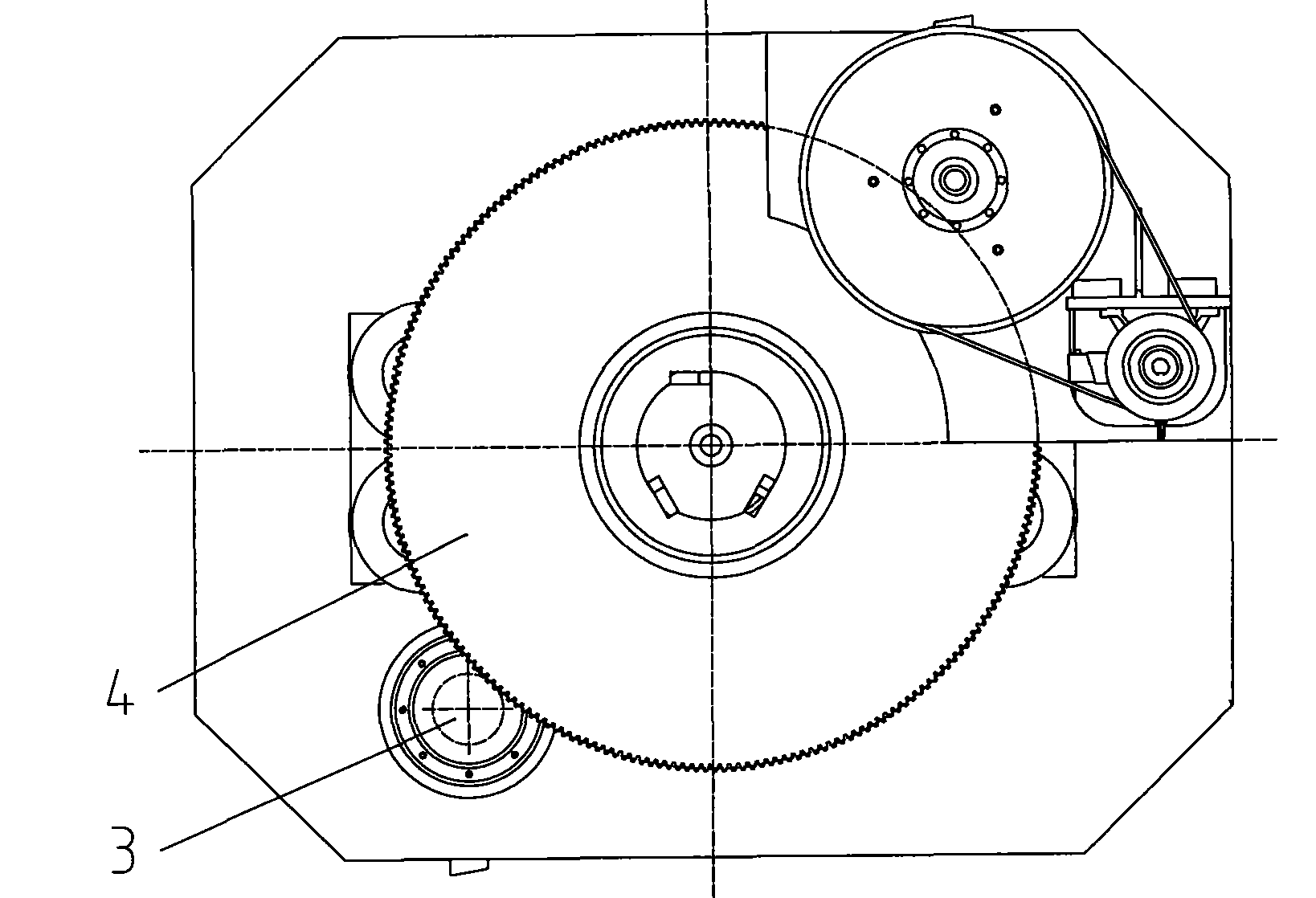

[0019] Such as Figure 1-3 As shown, a gear box 5 is installed above the support 9, and the pinion 3 is rotatably located in the gear box 5. The outer rim of the press flywheel 4 is processed into a large gear, which meshes with the pinion 3. There can be even numbers of pinions 3, which are arranged symmetrically around the flywheel 4 along the circumferential direction, see image 3 , pinion 3 has two. The lower end of the pinion 3 is connected with the first motor 7 through a safety clutch 6 . The upper end of the pinion 3 is equipped with a brake 2 and a clutch 1 . The brake 2 is fixed on the gear box 5, the clutch 1 is fixed on the pinion shaft, and is driven to rotate by the second motor 8 installed on the gear box 5. Preferably, the second motor 8 is an ordinary motor, and the clutch 1 can be connected with the small gear. Gear 3 is connected or disengaged. The flywheel 4 is connected with the screw rod 12, and the screw rod 12 is installed in the beam and forms a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com