An assembled prefabricated square culvert forming device and its manufacturing process

A molding device and assembly technology, applied in the direction of manufacturing tools, unloading devices, ceramic molding cores, etc., can solve the problems of short service life, damage, low square culvert strength, etc., to reduce dumping and waste, and reduce production costs. , to ensure the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

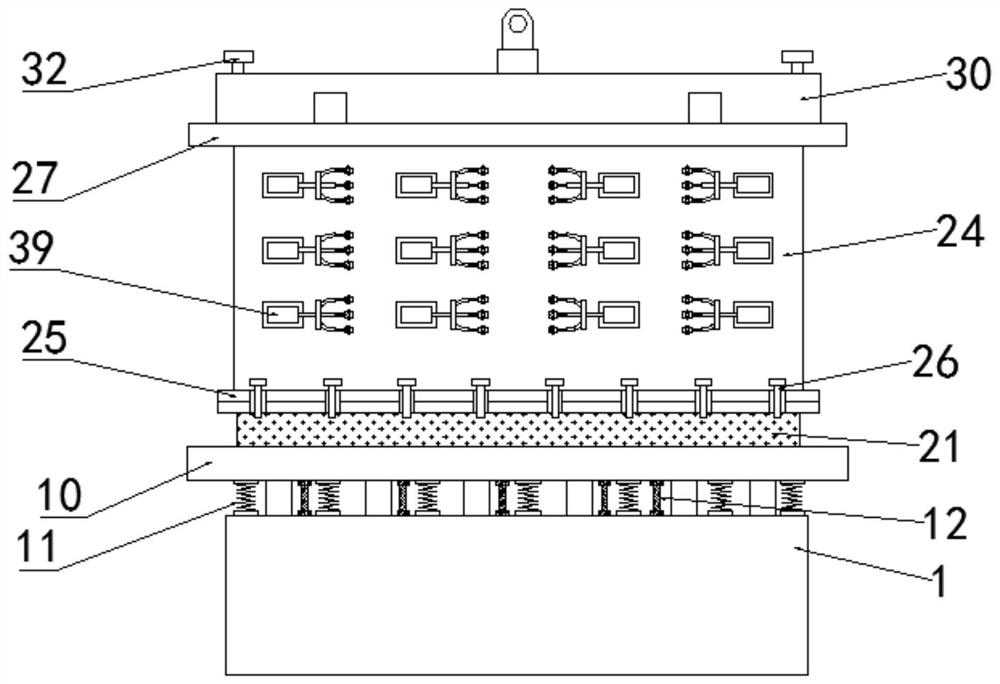

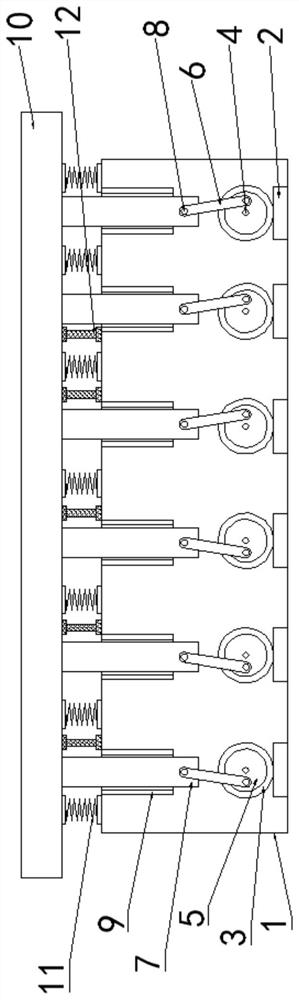

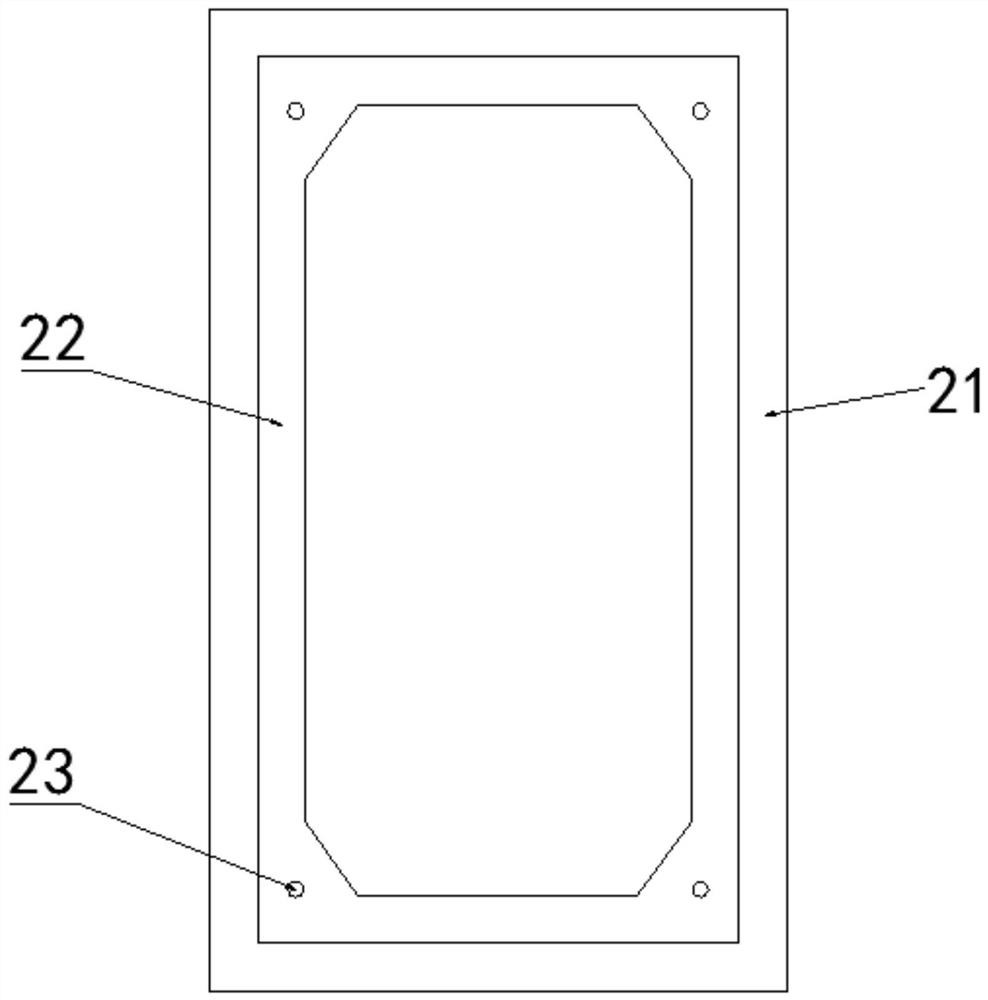

[0037] Such as Figure 1-8 As shown, an assembled prefabricated square culvert forming device and its manufacturing process according to an embodiment of the present invention include a base 1, and several vibrating devices are provided on the inner bottom of the base 1, and the vibrating devices include a motor base 2, The bottom of the motor seat-2 is connected and fixed with the inner bottom of the base 1, the top center of the motor seat-2 is provided with a motor-3, and the side output end of the motor-3 is provided with a motor shaft-4 The side of the motor shaft 1 away from the motor 3 is provided with a runner 5, the outer surface of the other side of the runner 5 is provided with a connecting rod 6, and the inner top of the base 1 is provided with several The sleeve 9 on the top of the base 1 is provided with a load-bearing column 7 inside the sleeve 9, and the other end of the connecting rod 6 is connected to the side bottom of the load-bearing column 7, and the two ...

Embodiment 2

[0039] Such as Figure 1-8 As shown, the buffer spring 11 is a compression spring, and the buffer spring 11 is made of a high-strength material. A spring washer is respectively provided at both ends of the buffer spring 11, and the two spring washers are respectively connected to the support The bottom of the board 10 and the top of the base 1 are connected and fixed.

Embodiment 3

[0041] Such as Figure 1-8 As shown, the elastic rod 43 is made of spring steel material, the return spring 45 is a tension spring, the strut 42 is an arc-shaped structure, the impact block 44 is a rectangular structure, and the impact ball 46 It is a hemispherical structure, and both the impact block 44 and the impact ball 46 are made of low alloy steel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com