Excitation device for detecting mechanical waves of a wood material

A wood material and excitation device technology, applied in the direction of using sonic/ultrasonic/infrasonic waves to analyze solids, can solve the problems of troublesome debugging, limited detection speed, difficult maintenance, etc., and achieves low equipment operation failure rate, positioning and hitting Accurate, work-efficiency-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

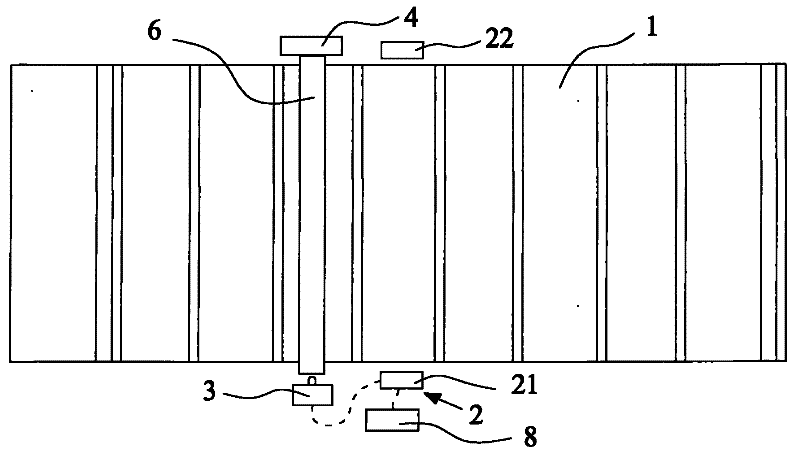

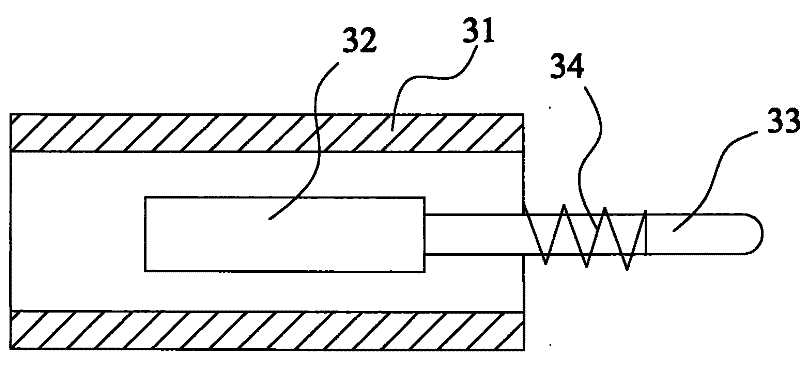

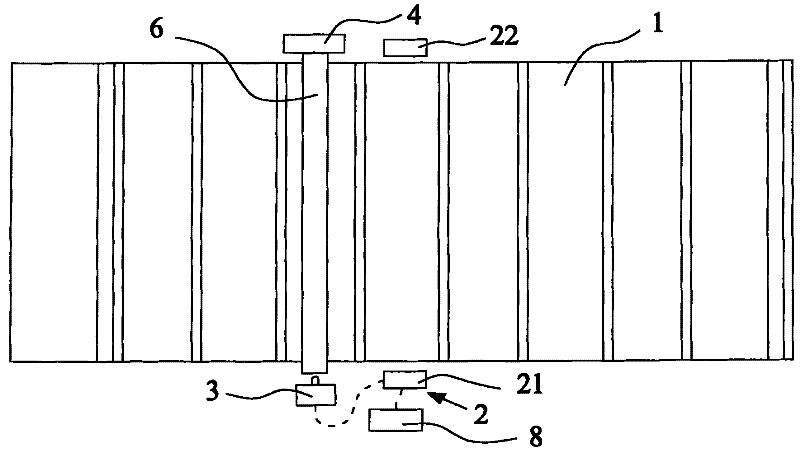

[0030] like figure 1 As shown, the present invention includes: a laser sensor 2 , a striker 3 , and a signal pickup 4 . The laser sensor 2 is arranged on one side of the transmission mechanism 1 of the detection line, and is used for online detection of the position of the wooden material 6, and determines the center striking moment according to the transmission speed and the size of the wooden material 6; the striker 3 is arranged on the transmission One side of the mechanism 1 is used to strike the central area of the end of the wooden material 6 according to the striking moment instruction of the laser sensor 2; the signal pickup 4 is arranged on the other side of the transmission mechanism 1 opposite to the striker 3, It is used to receive the mechanical wave signal generated on the wooden material 6 . The mechanical wave signal here may be a mechanical wave frequency signal or a mechanical wave velocity signal.

[0031] Because the present invention uses the laser se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com