Chassis articulated system of large-sized articulated coach

An articulation system and articulation technology, which can be used in the direction of connecting the channel of the vehicle, the vehicle parts, the steering mechanism of the front and rear tandem vehicles, etc., can solve the problems of trouble, high maintenance cost, unreasonable axle load distribution of the whole vehicle, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

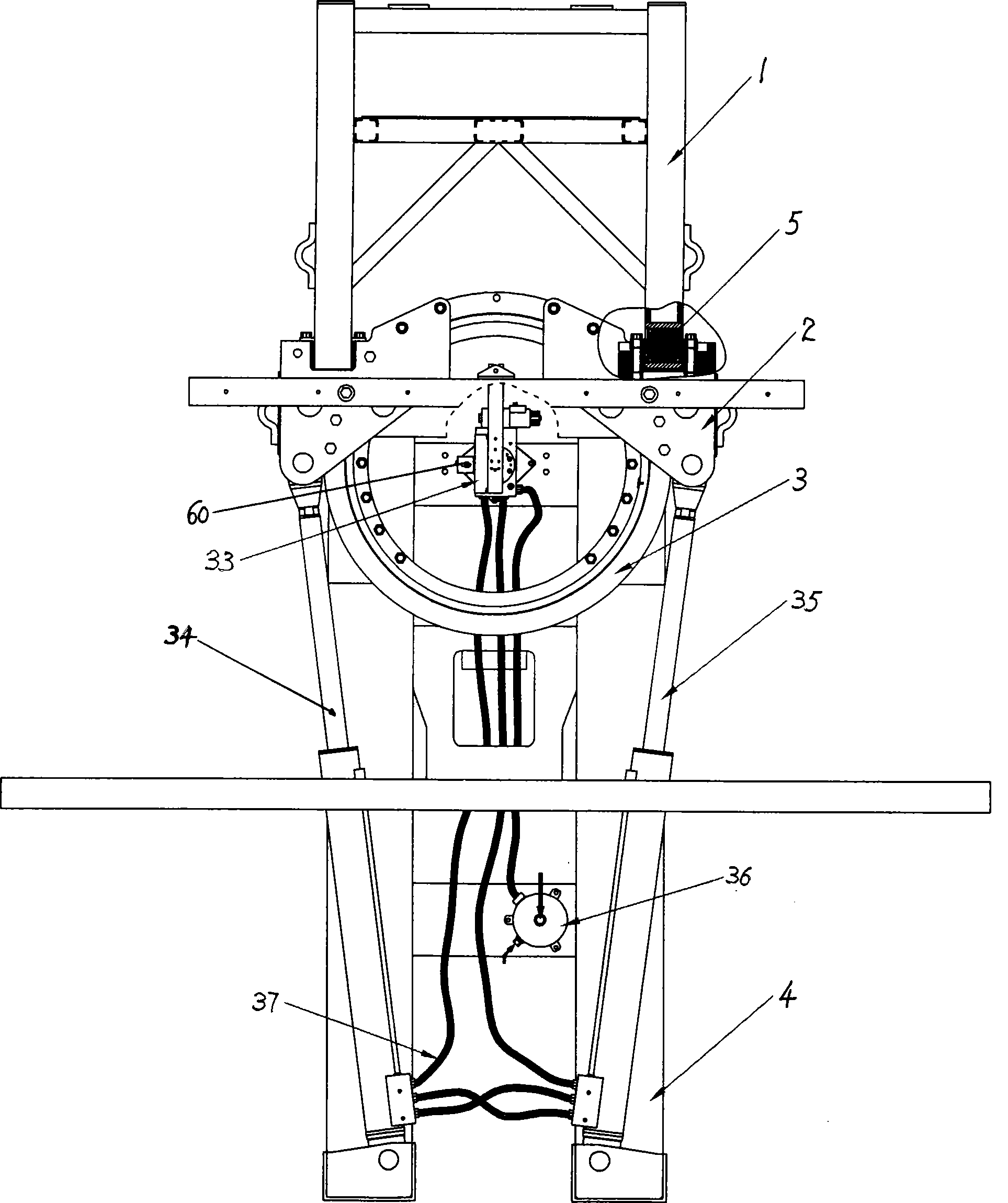

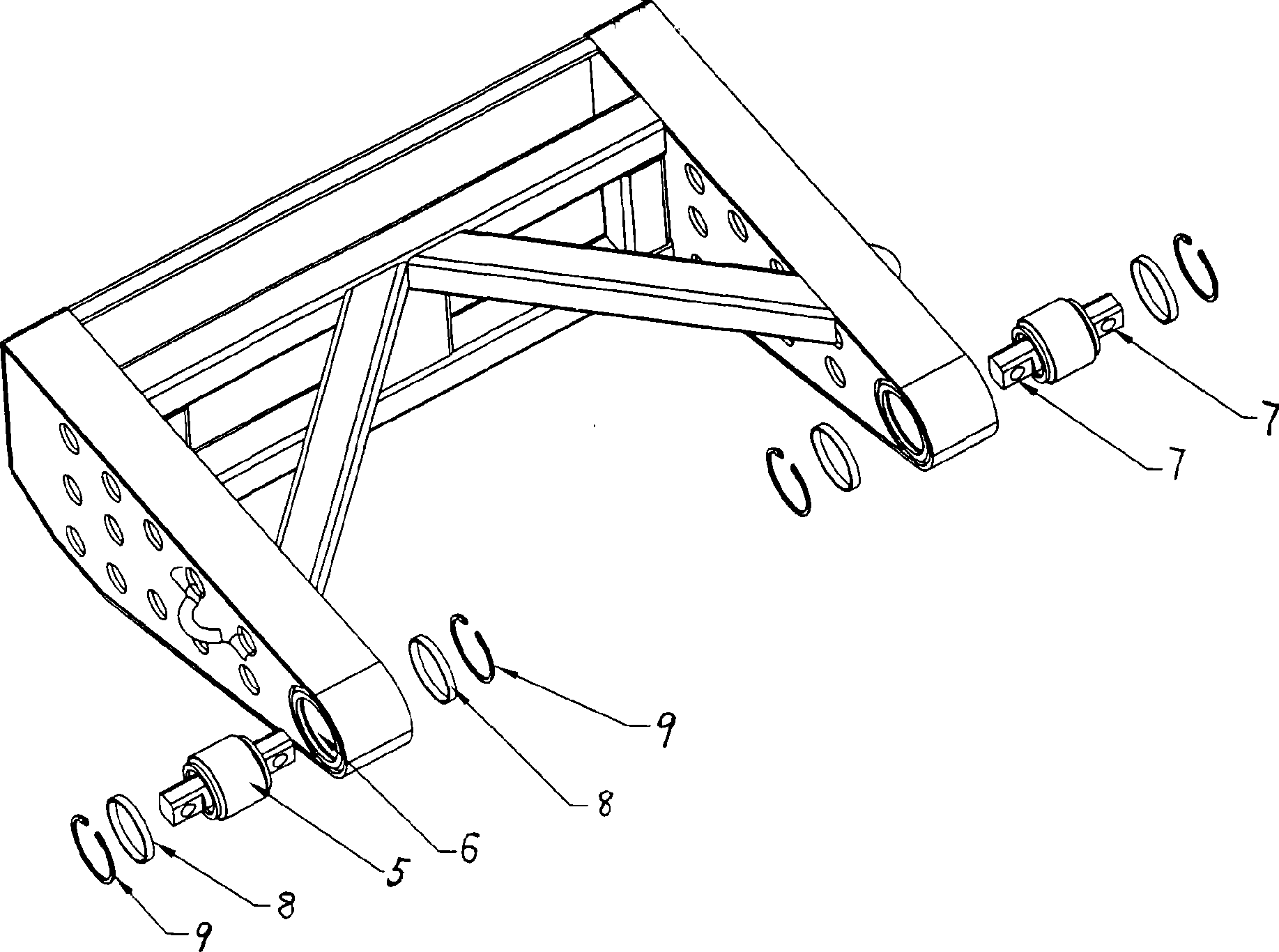

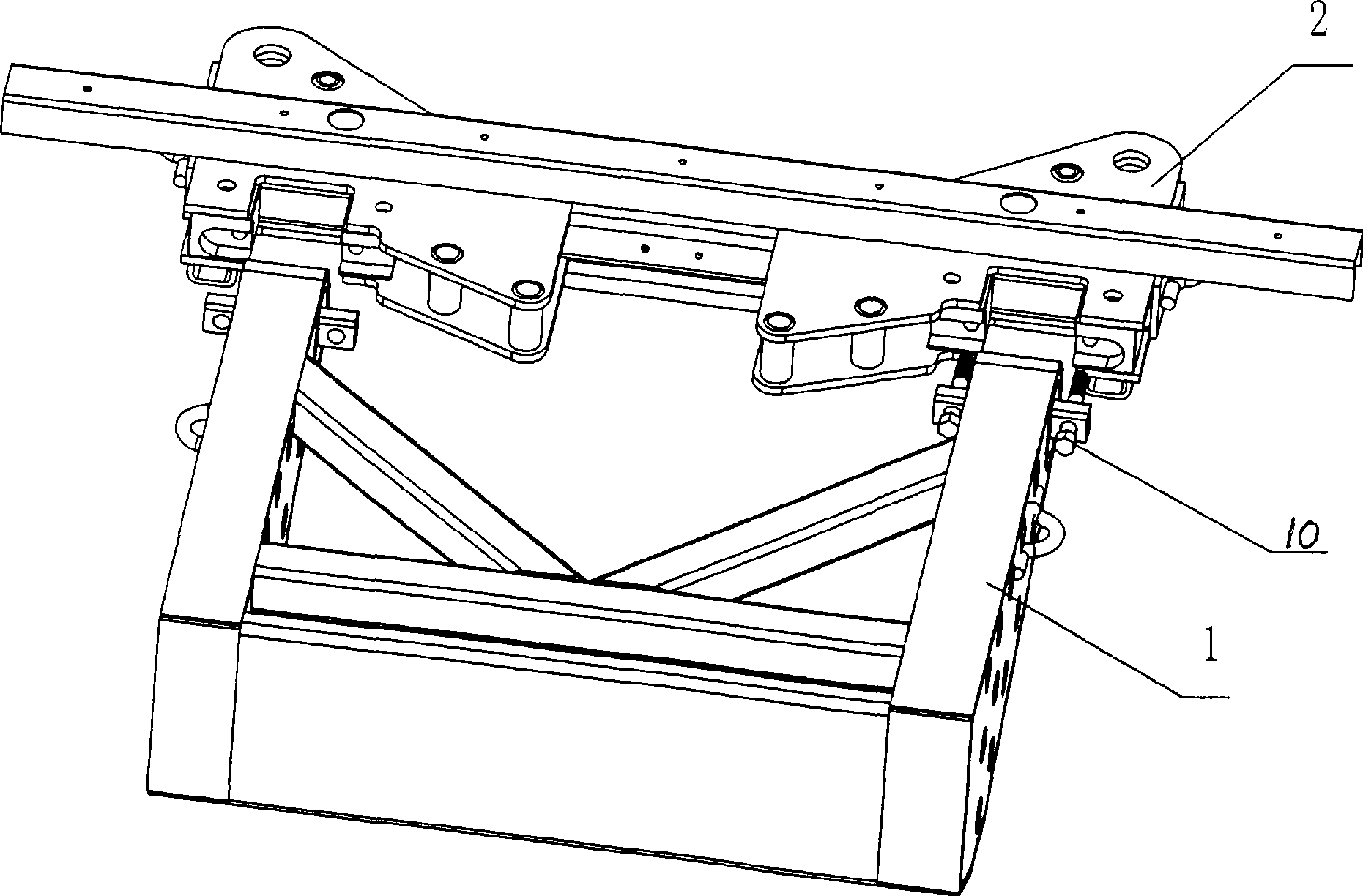

[0037] figure 1 It is a structural schematic diagram of the chassis articulation system disclosed by the present invention, which is suitable for a large articulated bus with two or more rear engines and is 14 to 25 meters long. The chassis articulation system includes three parts: split truss structure, hydraulic control system and electric control unit. Among them, the split truss structure mainly realizes the articulation of the front and rear compartments of large-scale articulated buses; the hydraulic control system mainly provides damping force for large-scale articulated buses that increases with the increase of the front and rear corners to prevent large-scale articulation. When the bus is turning, the tires on the second axle will slip to prevent the front and rear cars from shearing; the electrical control unit is mainly to monitor the state of the large articulated bus, control the opening or closing of the solenoid valve and throttle valve in the hydraulic control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com