Helicopter rotor operation method and system

A helicopter rotor and control system technology, applied in the field of helicopter control, can solve the problems of actuators not working normally, no measurement and control scheme, no transmission mechanism, etc., shorten the development cycle, improve safety and survivability, and facilitate The effect of integration

Inactive Publication Date: 2010-11-10

NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

View PDF0 Cites 24 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In this design scheme, the actuator is located near the tip of the blade in the radial direction, where the centrifugal force is huge, and the actuator will not work normally under this action; There is no transmission mechanism between the actuators; the pitch change spring of the blade root is similar to the pitch change rod of a conventional helicopter, which will also produce a large waste resistance; in addition, the plan does not mention the corresponding measurement and control plan, so it is considered that the flap control is open loop control

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

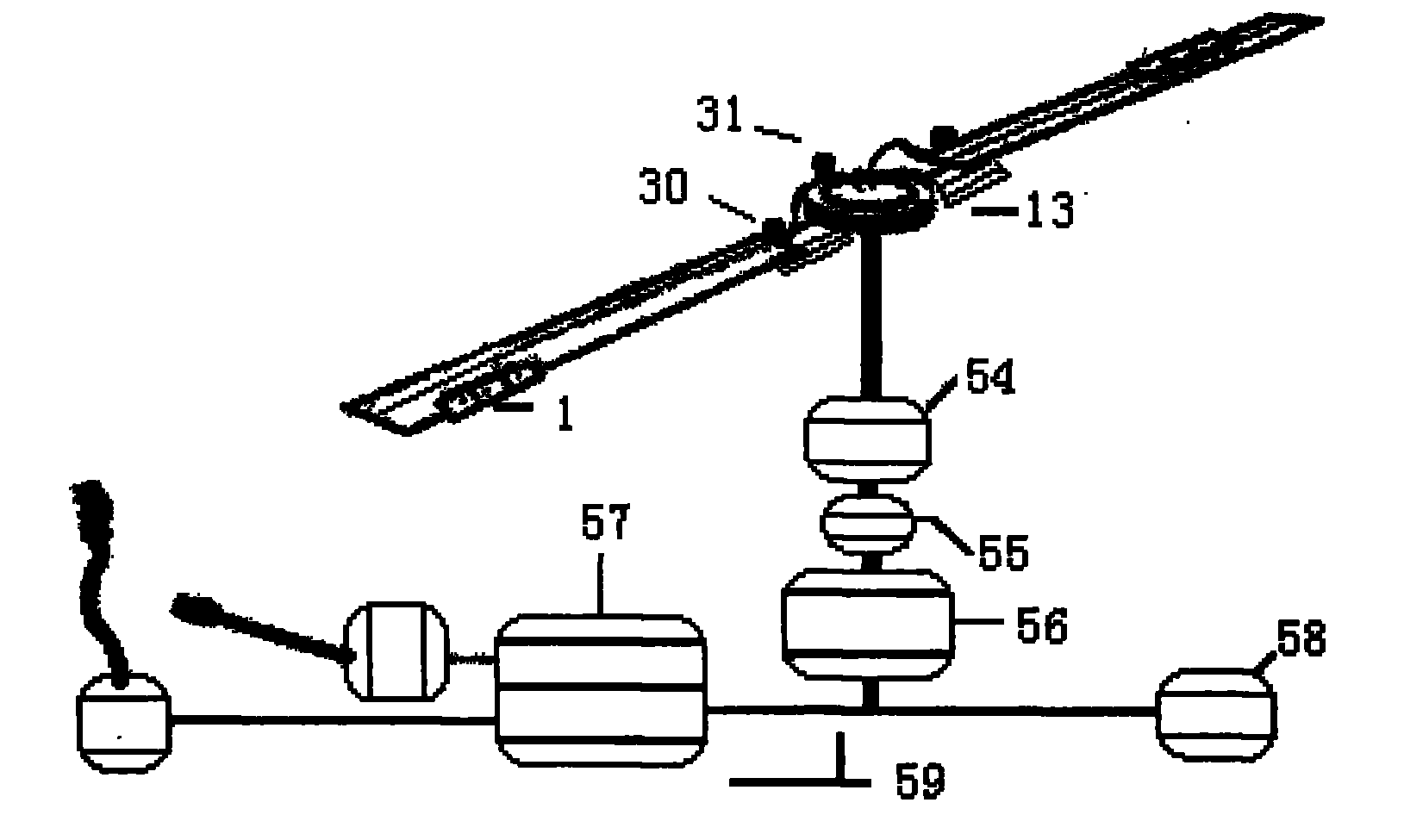

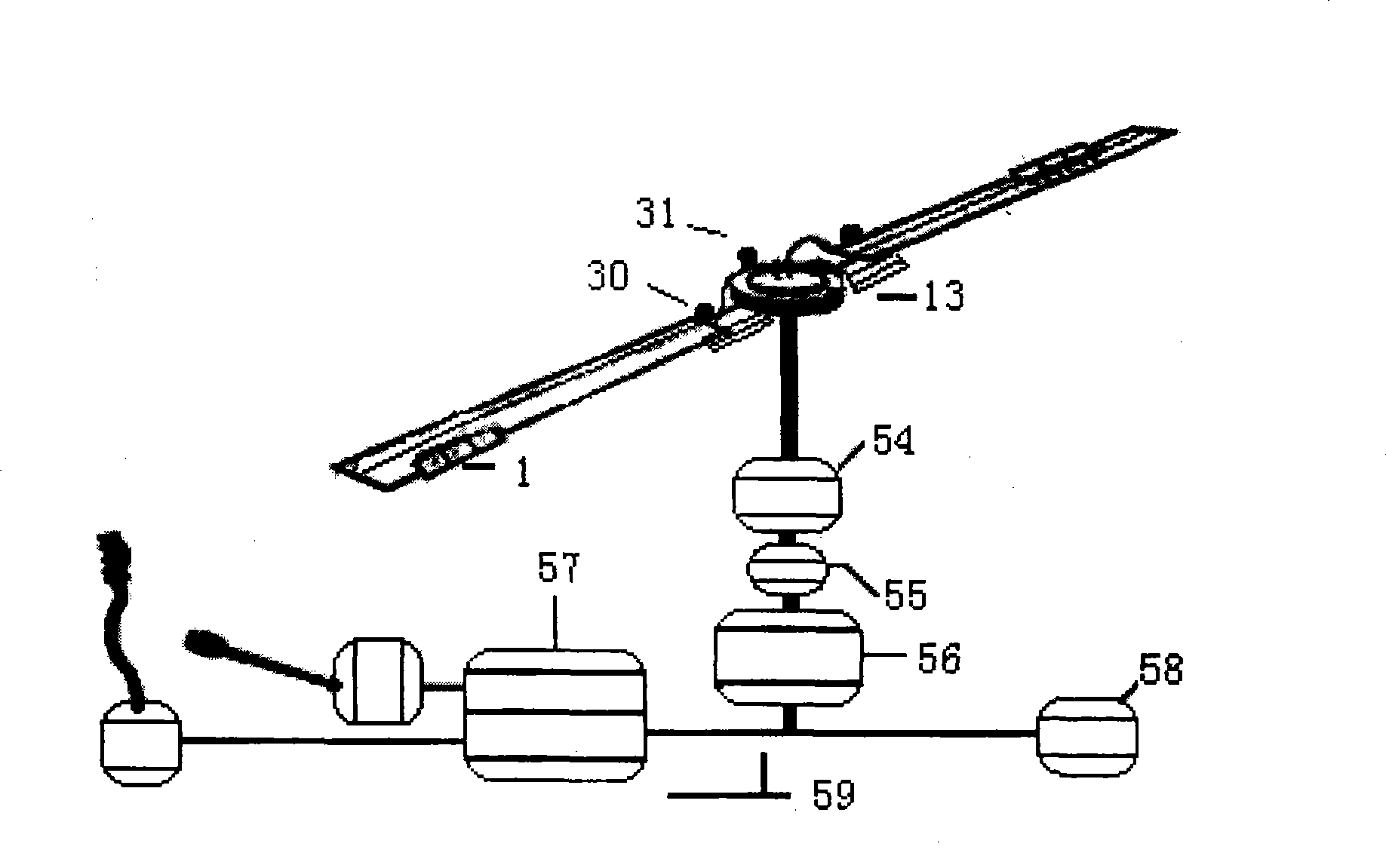

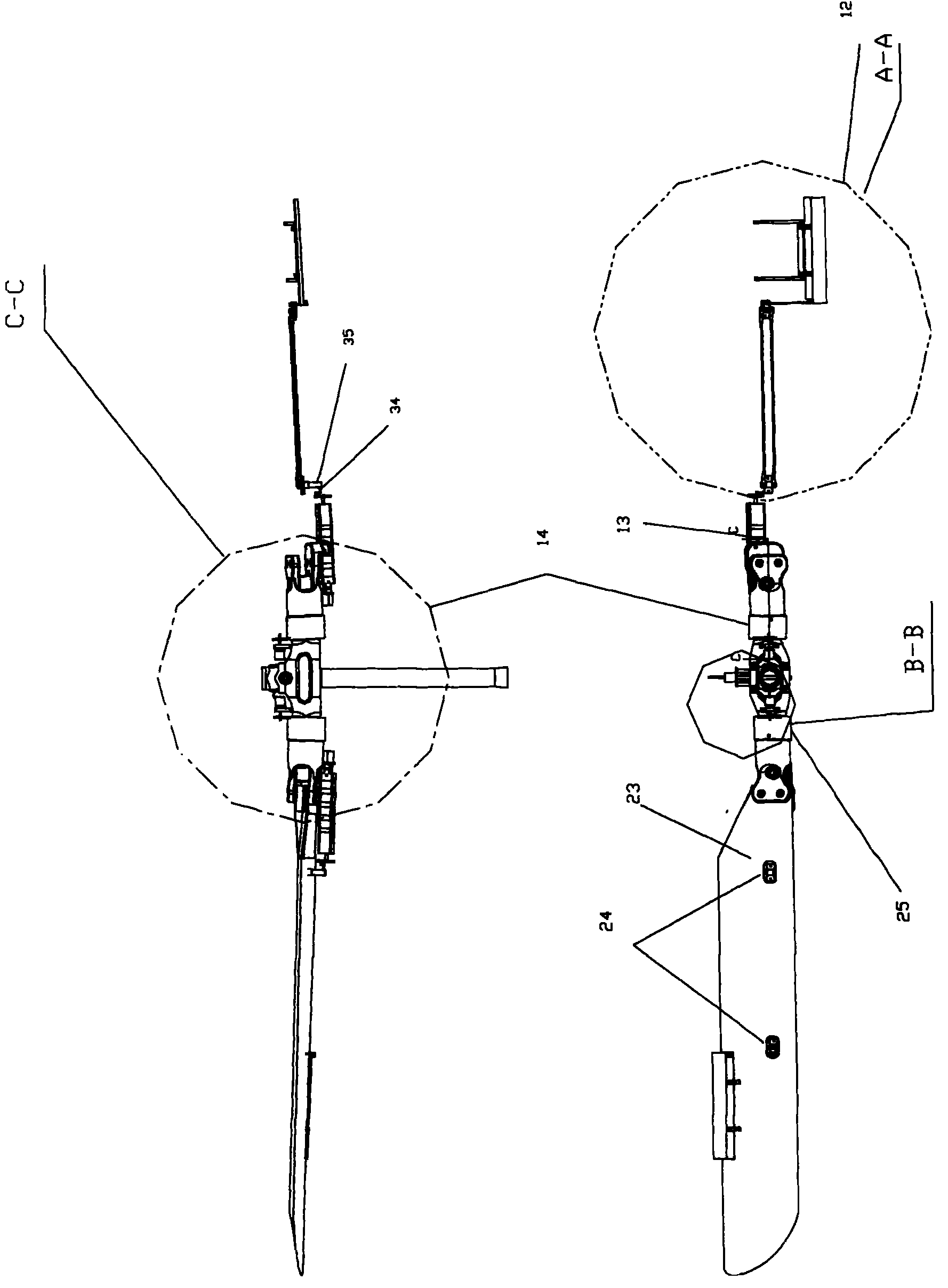

The invention relates to a control method and a system of a helicopter rotor, which belongs to the technical field of helicopter operation. The control method is characterized in that the distance changing of a blade is realized by adopting an actuator positioned on the stinger of each propeller boss to drive a flap positioned at the rear edge of the blade, so as to realize the control of a rotorsystem. The system comprises a demountable flap (1) installed at rear edge of the blade, torque soft propeller bosses (14), an actuator (13) installed on the stinger of torque soft propeller bosses, a flap control mechanism (1) with one end being connected with actuator (13) and the other end thereof being connected with the flap (1), and a test control system (59). The control method and the system have the advantages that the screw piston of each blade can be independently controlled, the structure is simple, the weight is light, the controllability is good, and the reliability and the security are high.

Description

Helicopter rotor control method and system Technical field The invention relates to a helicopter rotor control method and system, belonging to the technical field of helicopter control. technical background Due to its unique flight characteristics, the helicopter can hover, vertically lift, and fly in any direction, making it unique in the large family of aircraft; the reason why the helicopter has this ability is mainly due to the rotor and its operation. system. The rotor and its control system are the key components of the helicopter, which have an important impact on the performance, control stability and flight safety of the helicopter. Existing helicopter generally realizes helicopter manipulation by indirectly manipulating the automatic tilter, and the basic principle of its work is shown in the introduction in the reference: (Bosi. Russian Helicopter founder--Yuriev. , 2001(3).5~6.). The automatic tilter is composed of a rotating ring and a non-rotating ring. T...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G05D1/08B64C27/615B64C11/44G01B11/26

Inventor 陆洋夏鹤鸣王浩文高正肖荣

Owner NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com