Multi-station fully automatic rolled paper packaging machine

A packaging machine, fully automatic technology, applied in the direction of paper product packaging, packaging, transportation packaging, etc., can solve the problems of low packaging efficiency, slow movement speed, slow conveying speed, etc., to reduce labor intensity of workers and speed up conveying speed , The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the embodiments and accompanying drawings.

[0035] The following examples are non-limiting examples of the invention.

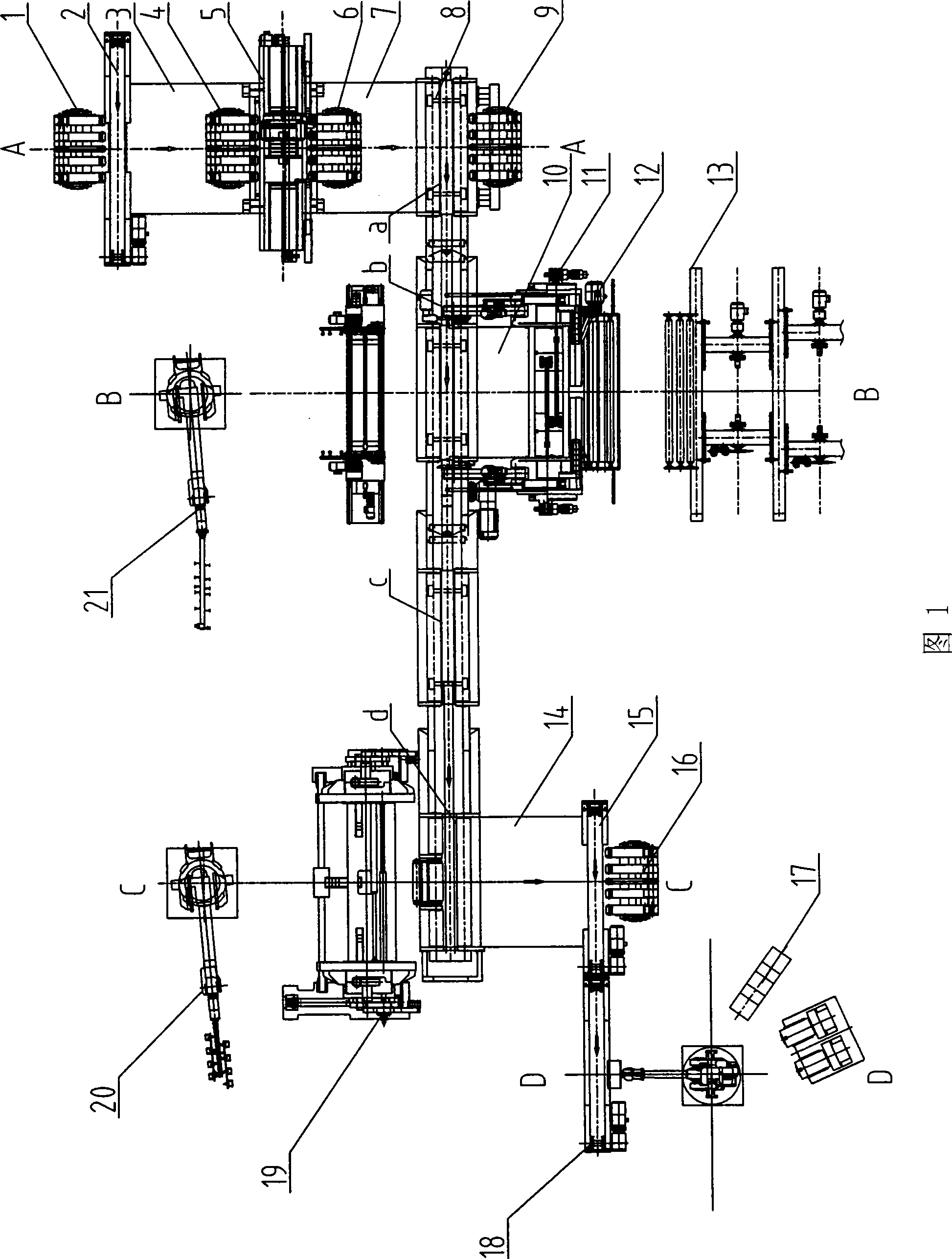

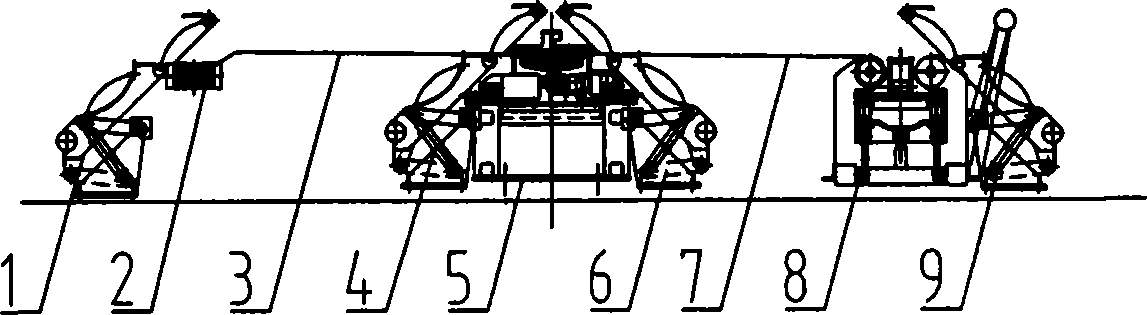

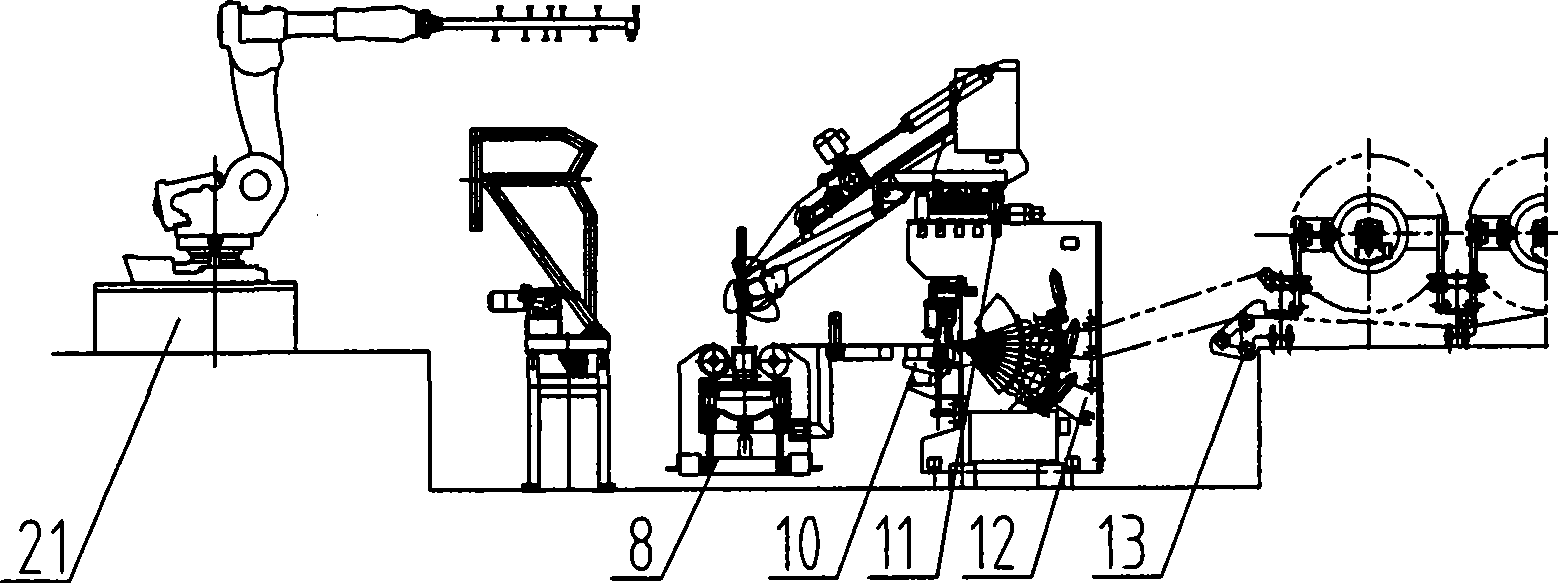

[0036]As shown in Figures 1, 1-1, 1-2, 1-3, and 1-4, the multi-station automatic paper roll packaging machine of the present invention includes a paper splicing system, a paper roll wrapping system, a thermal pressing system, and A paper roll conveying system for moving the paper roll between the above-mentioned systems and a control system for controlling the above-mentioned systems. Wherein, the paper roll conveying system adopts the station moving car system 8, and the station moving car system 8 includes a station frame 812, and the station rail 809 and the station trolley 807 on the station rail are arranged on the station frame 812 , the paper splicing system, paper roll wrapping system and thermal pressing system are arranged near the station frame 812 in seque...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com