Buoy for DME fuel tank

A technology of fuel tanks and buoys, which is applied in the direction of buoy liquid level indicators, the arrangement combined with the fuel supply of internal combustion engines, and the charging system, which can solve problems such as the inability to correctly measure the liquid level of DME fuel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

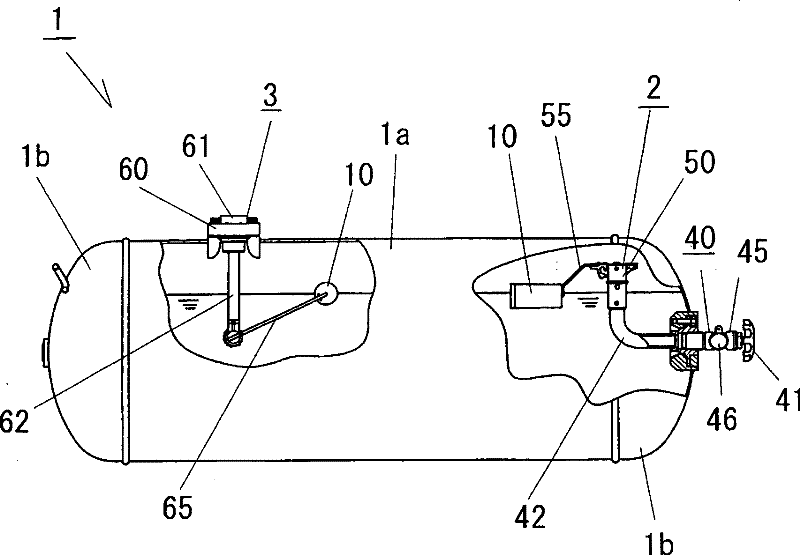

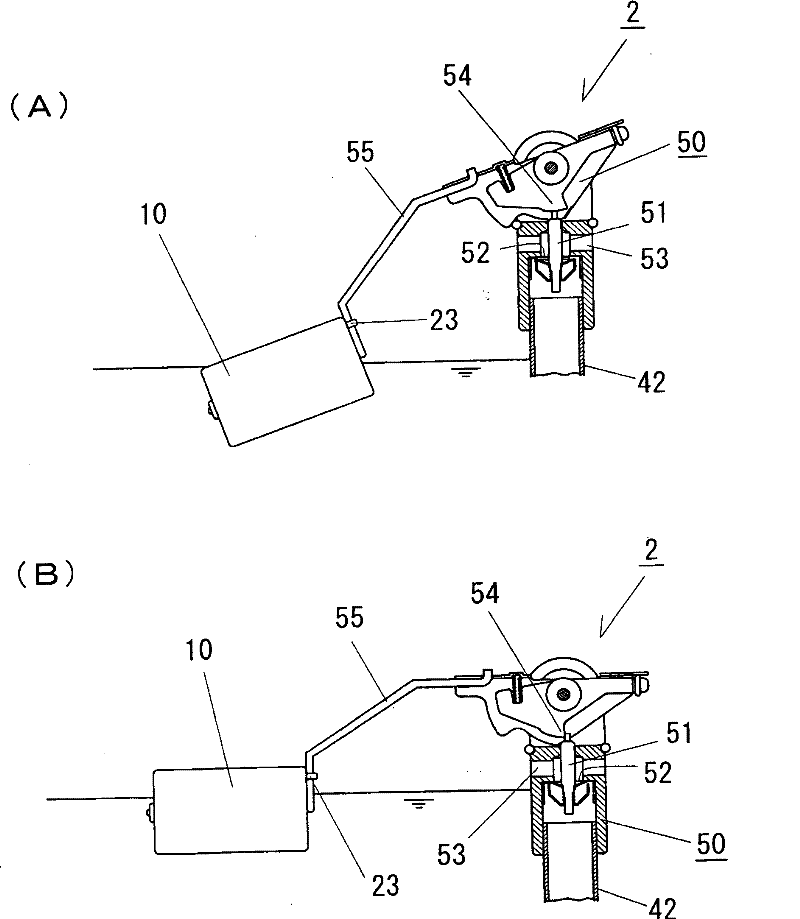

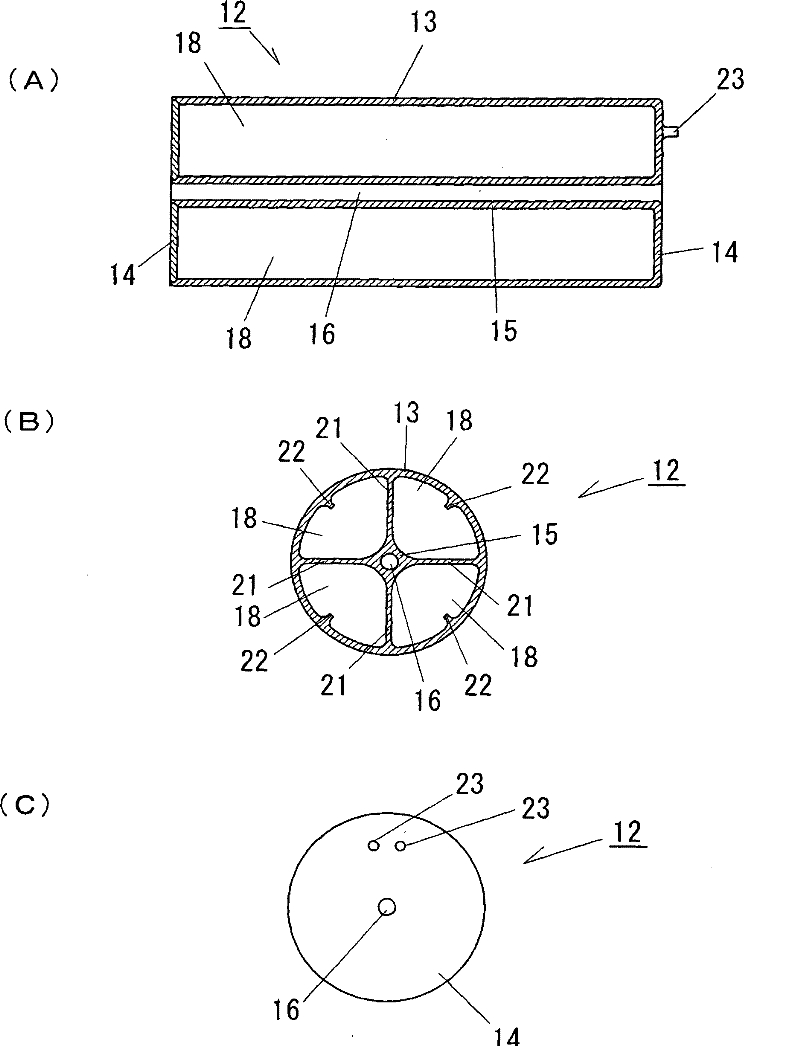

[0047] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

[0048] First, a immersion test was performed as a preliminary test for studying the material for molding the DME fuel tank buoy of the present invention, and the test results will be described.

[0049] As the buoy installed on the liquid level display device or the overfill prevention device installed in the fuel tank storing LPG (liquefied petroleum gas) fuel, as mentioned above, foam rubber (foamed nitrile rubber) is generally used. moldings. This is because foamed rubber has relatively low density and relatively high tensile yield strength, so buoys molded from foamed rubber can be molded to have a required specific gravity lower than the density of LPG fuel, and can fully withstand the storage of LPG. The compressive strength of the internal pressure of the fuel tank. However, since the foam rubber used in the fuel tank of LPG fuel permeates DME fuel, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com