White light light-emitting device and manufacturing method thereof

一种发光装置、制作方法的技术,应用在电气元件、电路、半导体器件等方向,能够解决白光颜色不均匀、光程差异大、白光发光二极管应用受限等问题,达到出光颜色均匀的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

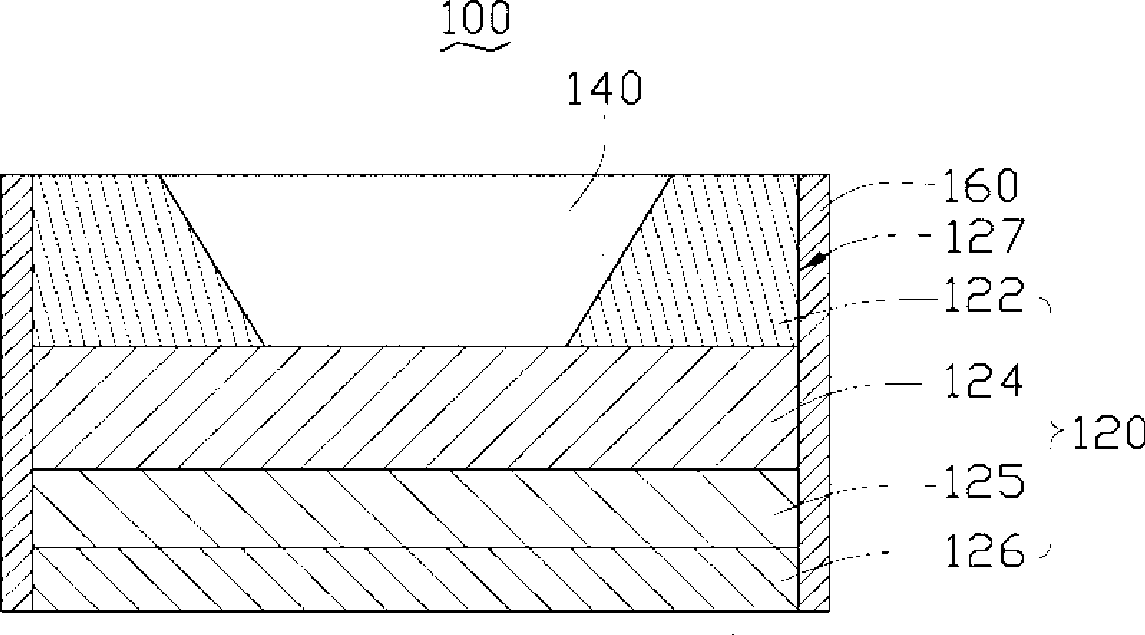

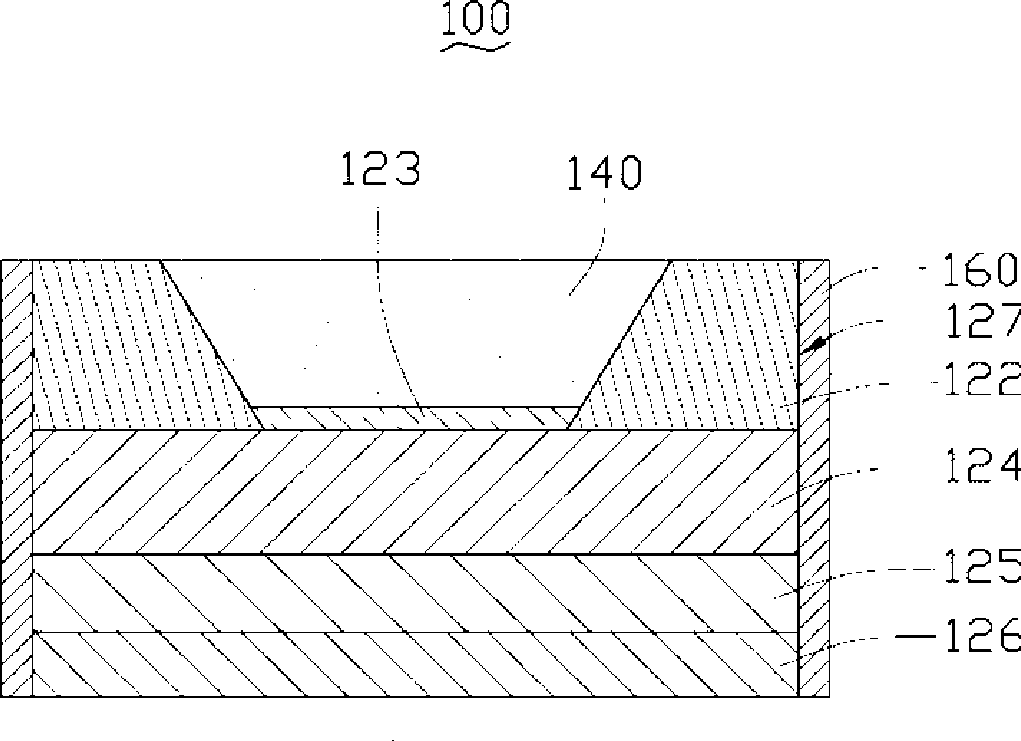

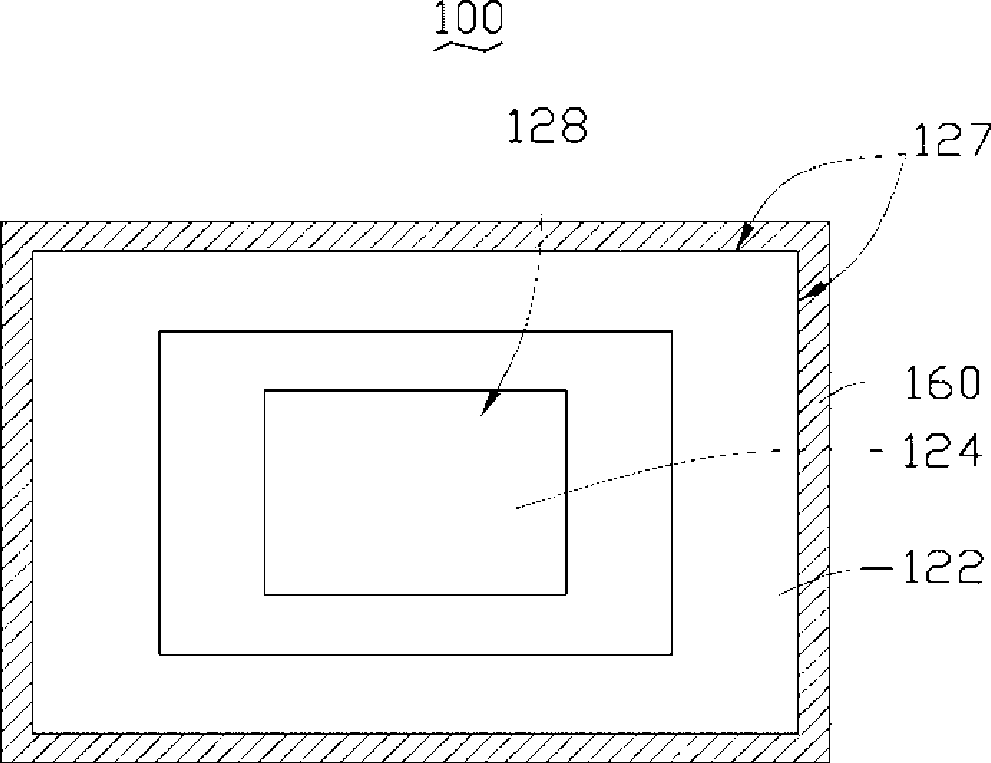

[0015] see Figure 1 to Figure 3 , a white light emitting device 100 provided by an embodiment of the present invention includes a light emitting diode chip 120 , a fluorescent substance layer 140 and a reflective layer 160 .

[0016] The light-emitting diode chip 120 includes a base 122, an n-type semiconductor layer 124, a p-type semiconductor layer 126 having a conductivity type opposite to that of the n-type semiconductor layer 124, and a The active layer 125 in between. The n-type semiconductor layer 124 , the active layer 125 and the p-type semiconductor layer 126 generally form a light emitting structure. The LED chip 120 has a plurality of side surfaces 127 .

[0017] The n-type semiconductor layer 124 , the active layer 125 and the p-type semiconductor layer 126 are disposed on the base 122 and arranged along a direction away fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com