Resin for blending with rubber, and rubber composition

A rubber composition and rubber technology, applied in the field of rubber compounding resin and rubber composition, can solve problems such as insufficient rubber adhesion, and achieve high adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

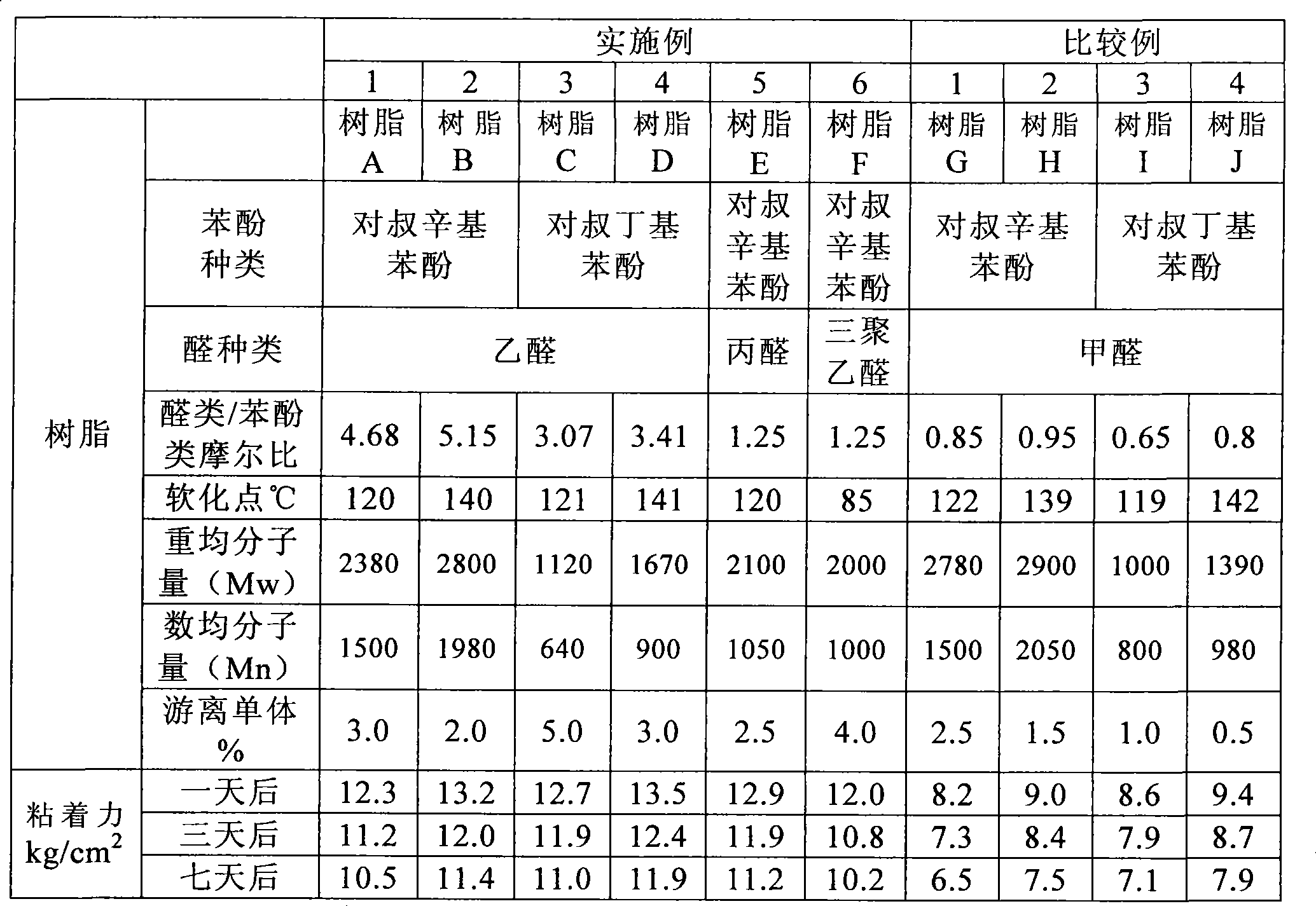

Examples

Embodiment 1

[0044] In a reactor with a stirring device, a reflux condenser and a thermometer, 1000 parts of p-tert-octylphenol, 1000 parts of acetaldehyde and 10 parts of p-toluenesulfonic acid were put into the reaction vessel under reflux for 3 hours. Next, dehydration and de-p-tert-octylphenol were carried out under reduced pressure until the amount of moisture and free monomer reached a predetermined level, and then it was taken out from the reactor to obtain resin A for rubber compounding. The softening point of this resin A was 120° C., and the free p-tert-octylphenol content was 3.0%.

Embodiment 2

[0046] In a reactor with a stirring device, a reflux condenser and a thermometer, 1000 parts of p-tert-octylphenol, 1100 parts of acetaldehyde and 10 parts of p-toluenesulfonic acid were put into the reaction vessel for 3 hours under reflux. Next, dehydration and de-p-tert-octylphenol were carried out under reduced pressure until the predetermined amount of water and free monomers was reached, and then it was taken out from the reactor to obtain resin B for rubber compounding. The softening point of this resin B was 140° C., and the free p-tert-octylphenol content was 2.0%.

Embodiment 3

[0048] In a reactor with a stirring device, a reflux condenser and a thermometer, 1000 parts of p-tert-butylphenol, 900 parts of acetaldehyde and 10 parts of p-toluenesulfonic acid were put in, and reacted under reflux for 3 hours. Next, dehydration and removal of p-tert-butylphenol were carried out under reduced pressure until the predetermined amount of moisture and free monomers was reached, and then it was taken out from the reactor to obtain resin C for rubber compounding. The softening point of this resin C was 121° C., and the amount of free p-tert-butylphenol was 5.0%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com