Manufacture use method of furniture type no-frame honeycombed sheet

A technology of honeycomb panels and furniture, which is applied in the direction of manufacturing tools, joining of wooden veneers, wood processing appliances, etc. It can solve the problems of affecting the shape of honeycomb panels, inconvenient transportation, and heavy weight, so as to achieve less harmful gas release and save wood Resource and manufacturing cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

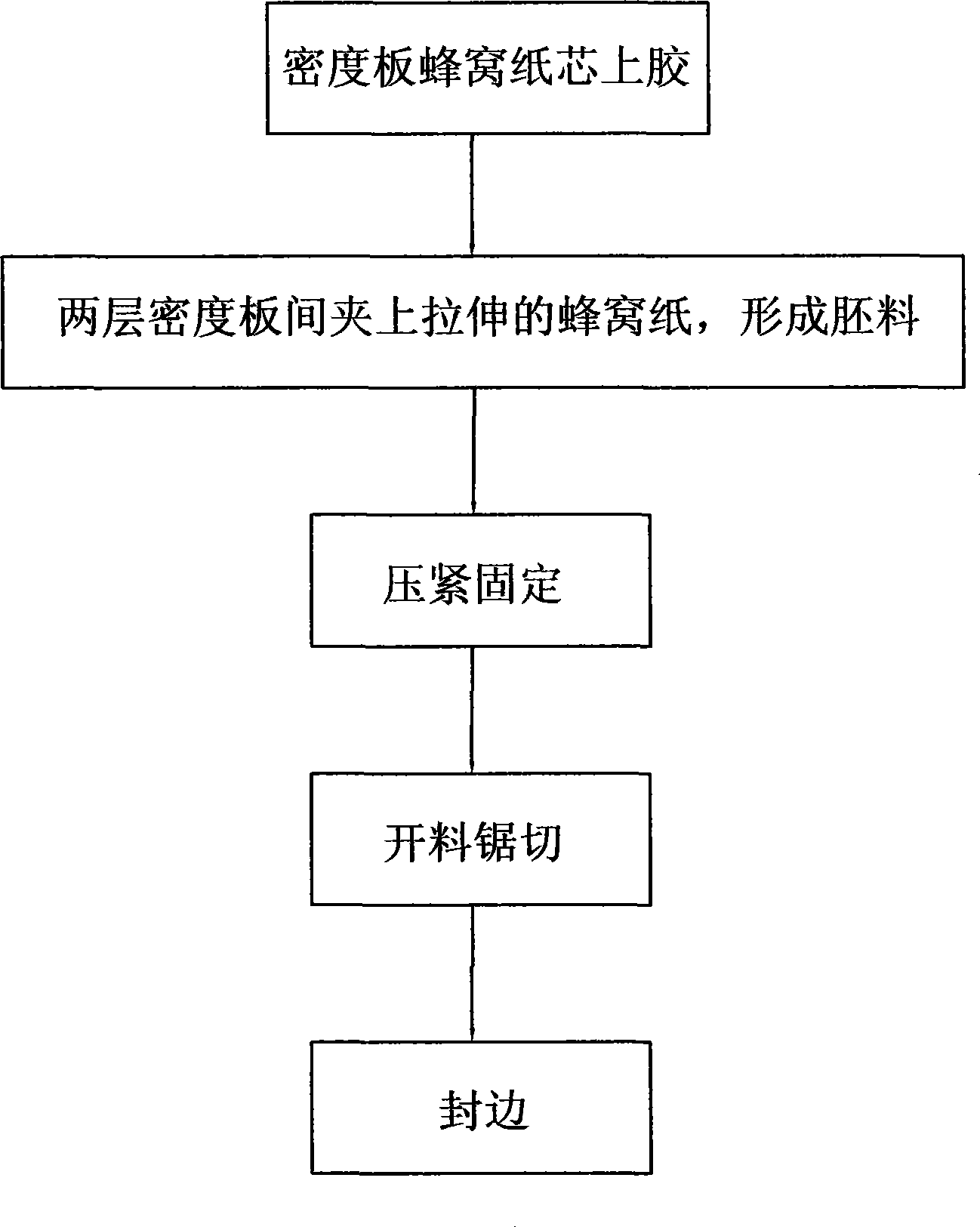

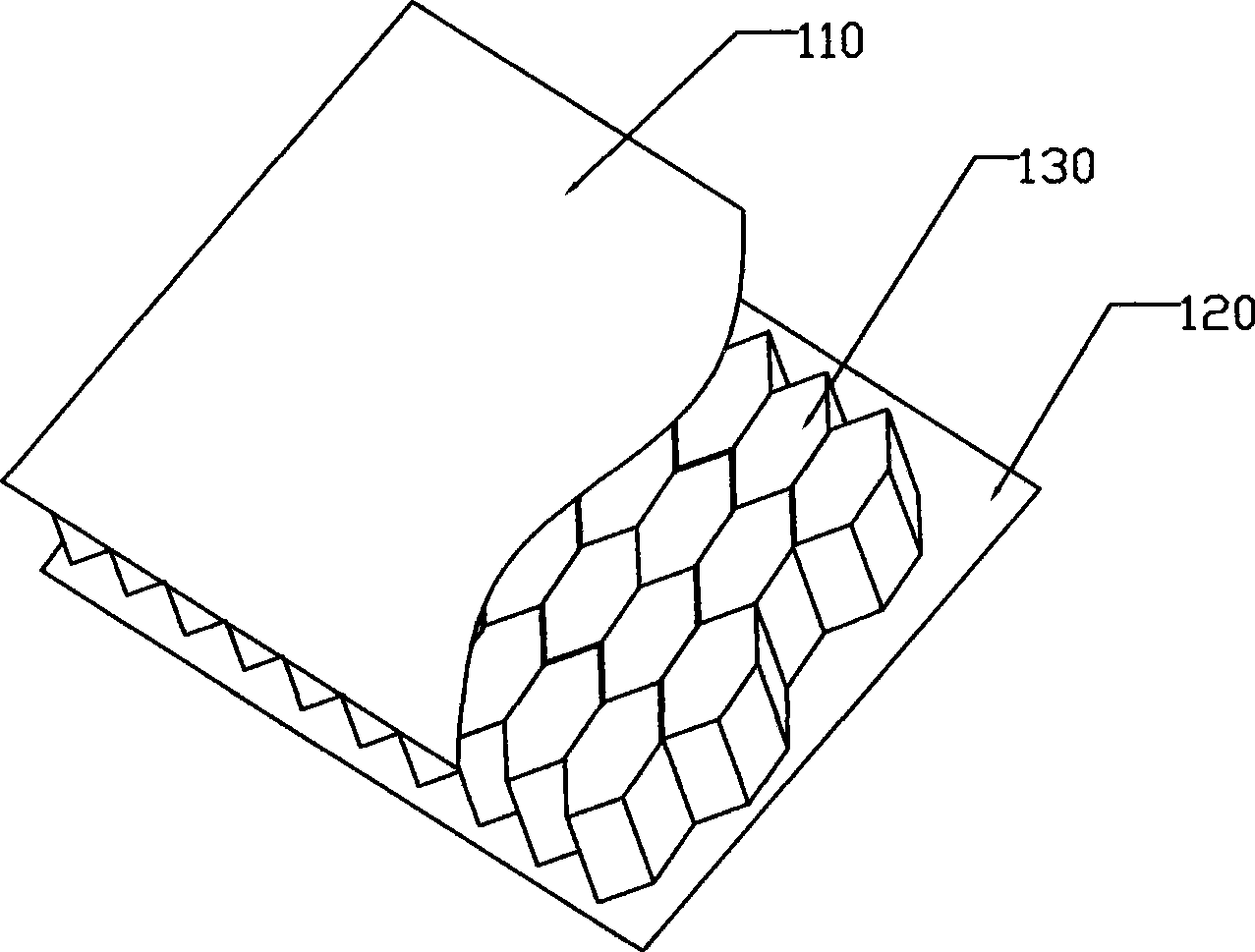

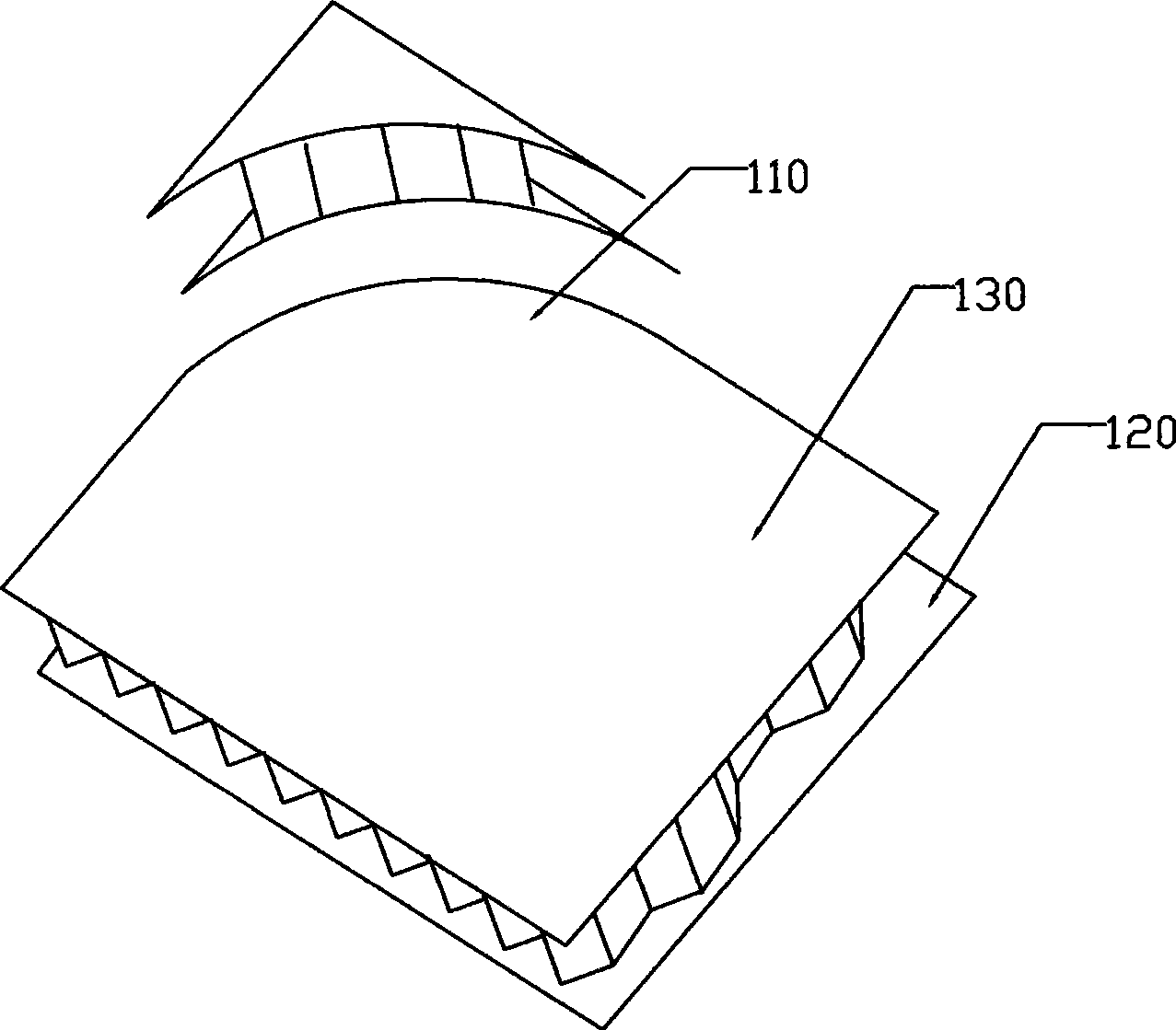

[0017] Such as Figure 1-Figure 4 As shown, first, 2 pieces of medium and high density boards are glued. In the glueing step, the glue can be applied to the contact surface between the inner side of the board and the honeycomb paper or on the contact part between the honeycomb paper and the board. The stretched honeycomb paper in the middle is formed as figure 2 The three-layer large-slab blank 100 shown includes medium and high-density boards 110 and 120 on both sides and honeycomb paper 130 sandwiched therein, and then the three-layer large-slab blank 100 is processed by hot pressing in a hot press Press and fix, and then image 3 As shown, use an electronic cutting saw or a panel cutting machine to cut the material into the required size and shape, and finally Figure 4 As shown, make supporting edge strips or embed solid particle board strips, and finally use an edge banding machine to seal the edges of the decorative edge strips.

[0018] The same principle, using CNC...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com