Filtration processing system and processing method of water supply plant

A treatment system and treatment method technology, applied in the field of tap water filtration treatment, can solve the problems of high ultrafiltration operation cost, non-compliance, and increased costs, and achieve the effects of reducing ultrafiltration flocculation processes, improving water utilization, and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

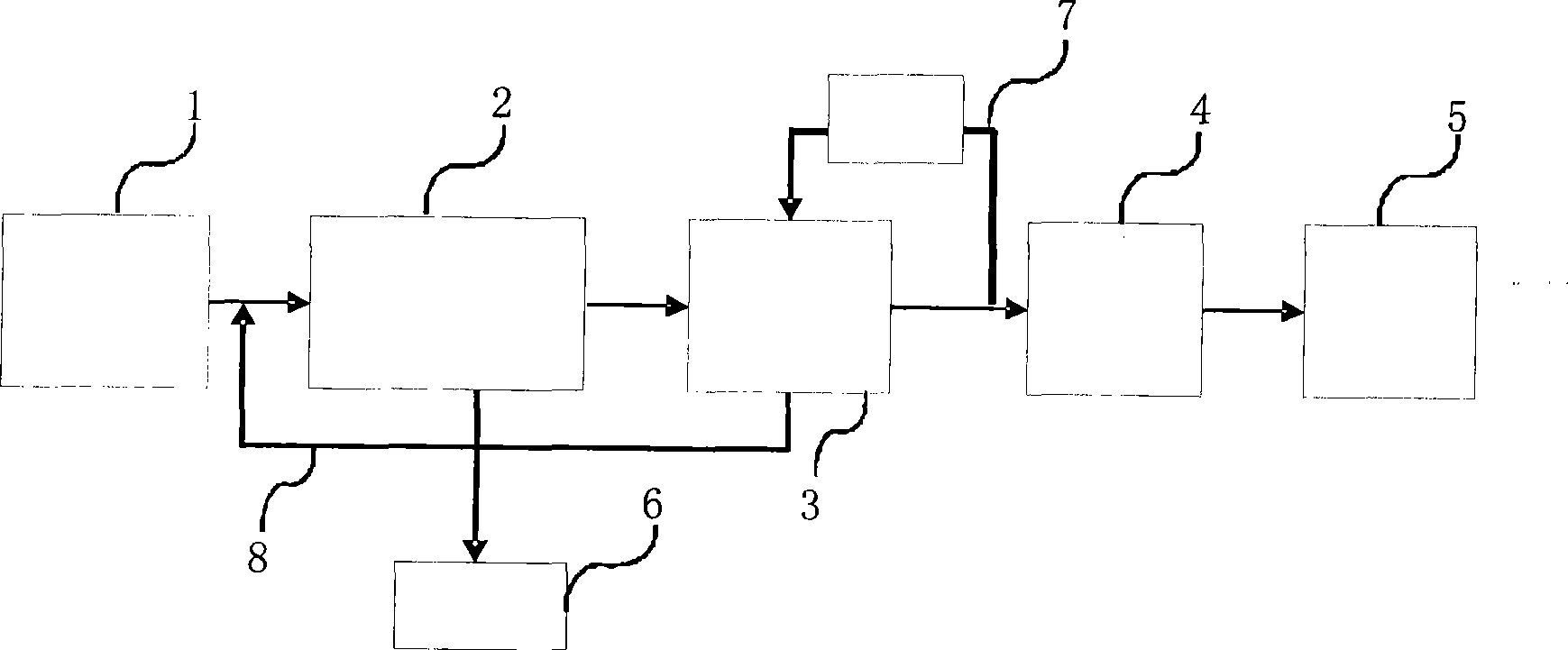

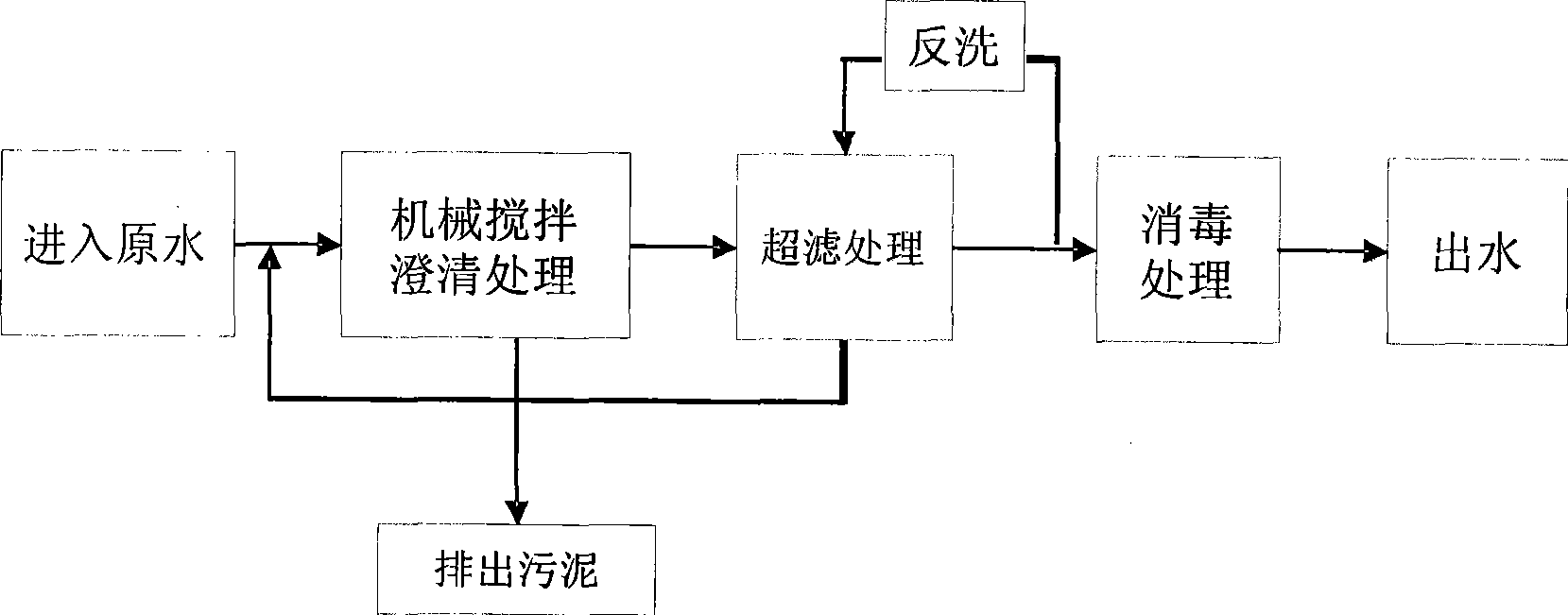

[0027] This embodiment provides a water supply plant filtration treatment system, which is used to filter water in the water supply plant, such as figure 1 As shown, the system includes:

[0028] clarifier 2, ultrafiltration equipment 3 and disinfection equipment 4; the clarifier 2 is provided with a raw water 1 inlet, the clarifier 2 is provided with a stirring device, the bottom of the clarifier 2 is provided with a mud outlet, and the outlet of the clarifier 2 The water outlet is connected with the ultrafiltration equipment 3 and the disinfection equipment 4 in turn, and the outlet pipeline of the ultrafiltration equipment 3 connected with the disinfection equipment 4 is provided with a backwash pipeline 7, and the cleaning water outlet at the bottom of the ultrafiltration equipment 3 passes through the reuse pipeline 8 times are connected to the water inlet of clarifier tank 2.

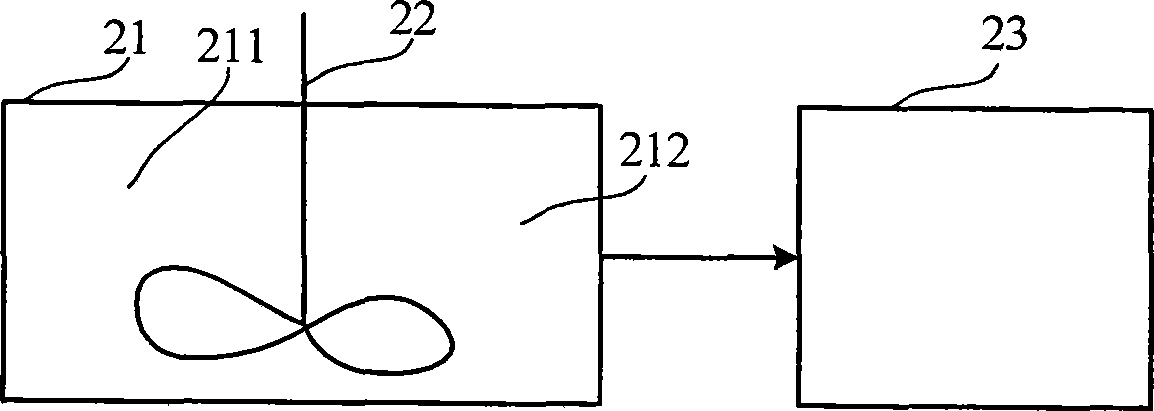

[0029] Such as figure 2 As shown, wherein, the clarification tank 2 is mainly composed of a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com