Supersonic flaw detector and its method ultrasonic inspection apparatus and inspection thereof

A flaw detection device and ultrasonic technology, which are used in measurement devices, analysis of solids using sonic/ultrasonic/infrasonic waves, and material analysis using sonic/ultrasonic/infrasonic waves, to achieve the effects of low comprehensive manufacturing cost, stable process and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

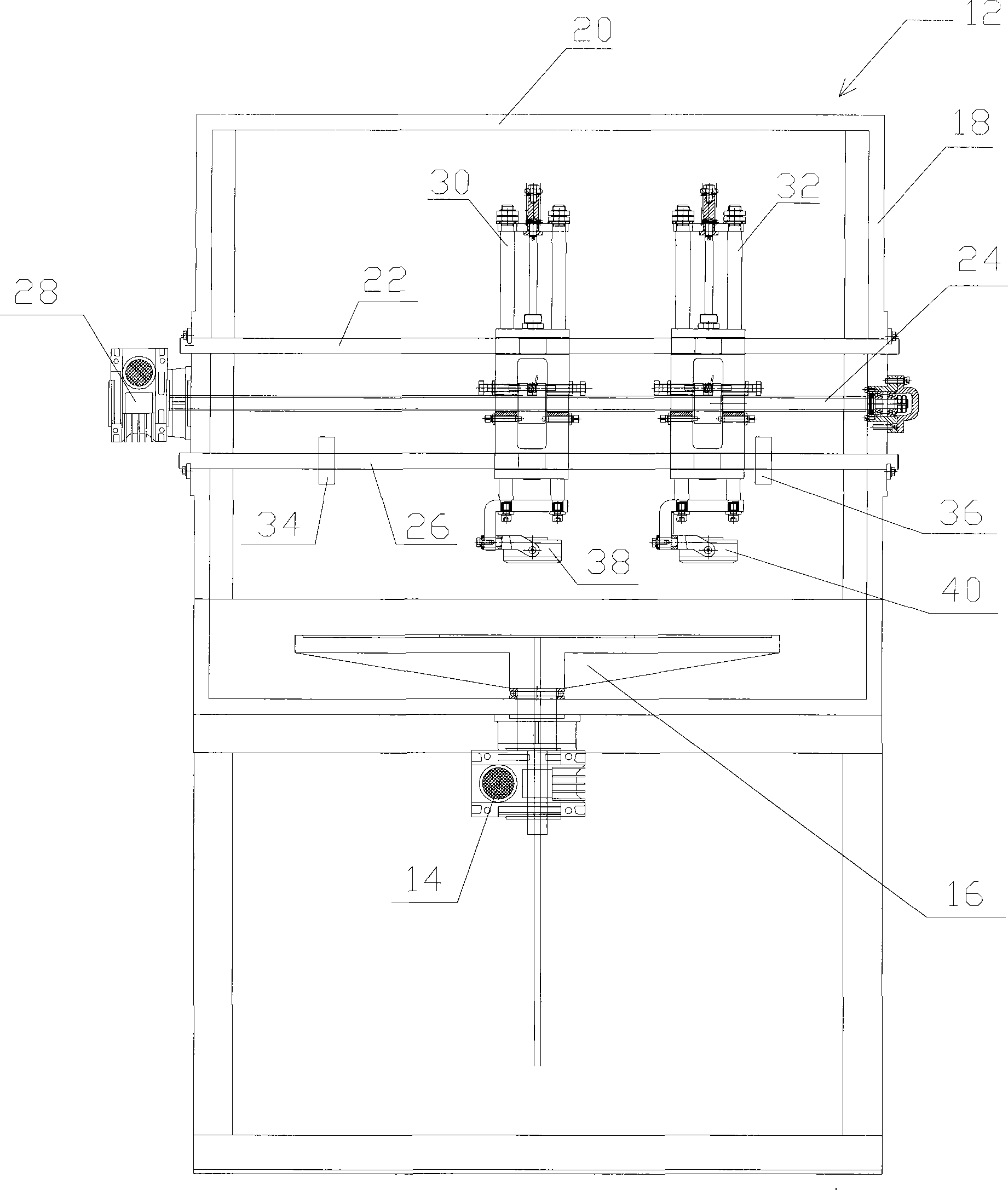

[0031] The invention discloses an ultrasonic flaw detection device, such as figure 1 As shown, an automatic scanning device 12 is included, and the automatic scanning device 12 includes a workpiece placement table 16 driven by a servo motor 14 to rotate; a gantry 18 positioned above the workpiece placement table 16; three mounting frames arranged parallel to the gantry beam 20 22, 24 and 26, wherein a mounting frame 24 in the middle is a screw rod, which is driven to rotate by a servo motor 28; two probe landing gears 30 and 32 are sleeved on the three mounting frames, and threaded with the screw rod mounting frame 24 therein connected, when the screw mounting frame 24 rotates, the probe landing gear 30 and 32 can be driven to translate axially; the two ends of a mounting frame 26 are respectively provided with limit switches 34 and 36, and the axial movement of the probe landing gear 30 and 32 is carried out. Limiting: Two probe landing gears 30 and 32 are provided with probe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com