Device for preventing sway of suspended load

A load and swing angle technology, applied in the direction of load suspension components, motor control, transportation and packaging, etc., can solve the problems of complicated calculations, difficult to set swing angle detectors, etc., and achieve the effect of easy adjustment of control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

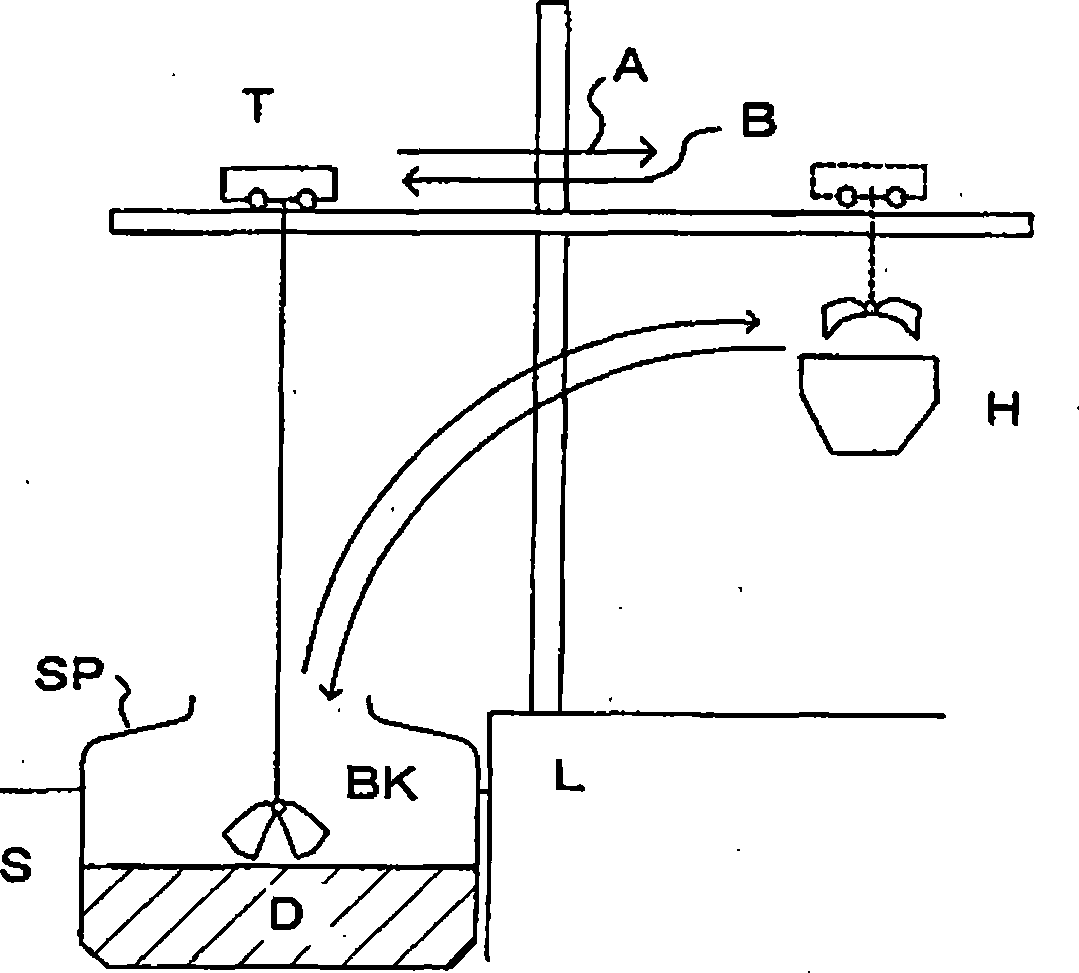

[0043] figure 1 It is a device schematic diagram of an unloader as an example of the object of the present invention.

[0044] figure 1 Among them, T is a trolley, A is for land, B is for ocean, H is hopper, SP is ship, BK is grab, S is ocean, L is land, and D is raw material.

[0045] In the figure, an unloader is installed on the land L facing the sea S, and a trolley T is installed at a specified height from the land L, and the built-in motor can horizontally reciprocate between the sea and the land.

[0046] A rope hoisting motor is also mounted on the trolley T, and a grab bucket BK is mounted on the front end of the rope.

[0047] The trolley moves to the top of the ship SP close to the land, lowers the grab bucket BK and grabs the load of the ship by the grab bucket BK, that is, the raw material D, then rolls up the sling to lift the grab bucket BK, and at the same time moves from the ocean S to the land L, and moves to the land Throw raw material D into the hopper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com