Soft smoothing agent for finishing after slopwork of wool and cashmere

A finishing and smoothing agent technology, applied in fiber processing, textiles and papermaking, animal fibers, etc., can solve the problems of unsatisfactory softness and fluffy feeling, and achieve the effect of good anti-felt shrinkage and good hand feeling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-10

[0047] Component A consists of silicone oil (E), (F), (J):

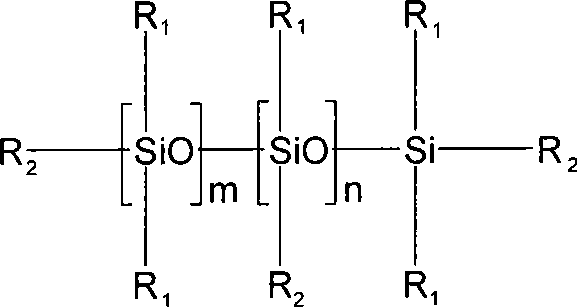

[0048] Silicone Oil (E)

[0049] Silicone Oil (F)

[0050]

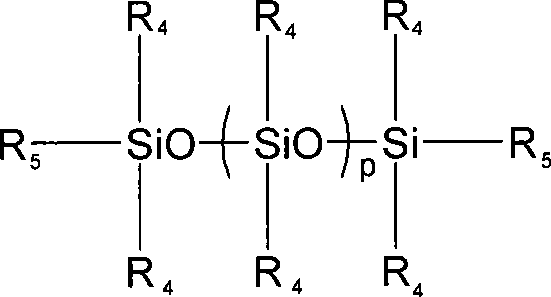

[0051] The structural formula of adding component B is

[0052]

[0053] The high dimethicone polydimethylsiloxane (G);

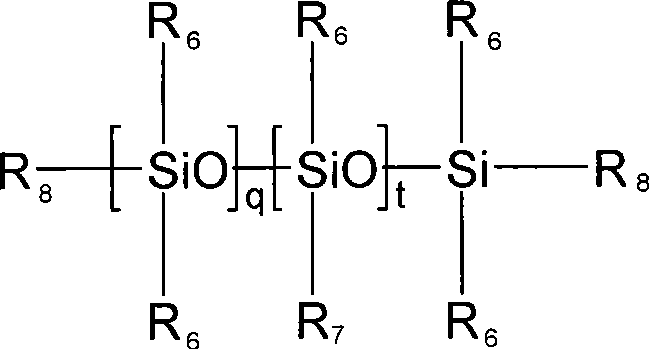

[0054] The structural formula of adding C component is

[0055] Silicone Oil (H)

[0056] ;\

[0057] Or add D component general formula (CH 3 )Si(OCH 3 ) 3 the oligomer (K),

[0058] The above-mentioned siloxanes are combined with surfactants BASF company T05, T07 is emulsified into an emulsion with a concentration of 30% by weight, and then diluted to 1%. After processing wool and cashmere garments, 5 people are used to blindly evaluate the hand feeling and anti-felt shrinkage, and measure the longitudinal and transverse shrinkage after washing. Washing conditions: bath ratio 1:50, temperature 40 ℃, time 15 minutes, weak alkaline or neutral detergent...

Embodiment 11-16

[0062] Among them, in component A,

[0063] In silicone oil (E), m=200, n=8;

[0064] In silicone oil (F), m=2800, n=5;

[0065] In silicone oil (J), m=1000, n=0;

[0066] In component B silicone oil (G), p=5500;

[0067] In component C silicone oil (H), q=0, t=35;

[0068] According to the same method of embodiment 1-10, its composition formula and use effect are as shown in table 2:

[0069] Table 2, embodiment 11-16 formula and use effect

[0070]

[0071] From Table 1 and Table 2, it can be concluded that the softening and smoothing agent of the present invention has better hand feeling and better anti-felt shrinkage compared with the existing amino-modified silicone oil smoothing agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com