Convection heat radiating device of led lamp

A light-emitting diode and heat dissipation device technology, which is applied in the cooling/heating device of the lighting device, the semiconductor device of the light-emitting element, the lighting device, etc., can solve the problems of fan damage and fan heat dissipation limitation, improve the heat dissipation effect and reduce the replacement of heat dissipation unit opportunity, the effect of significant cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

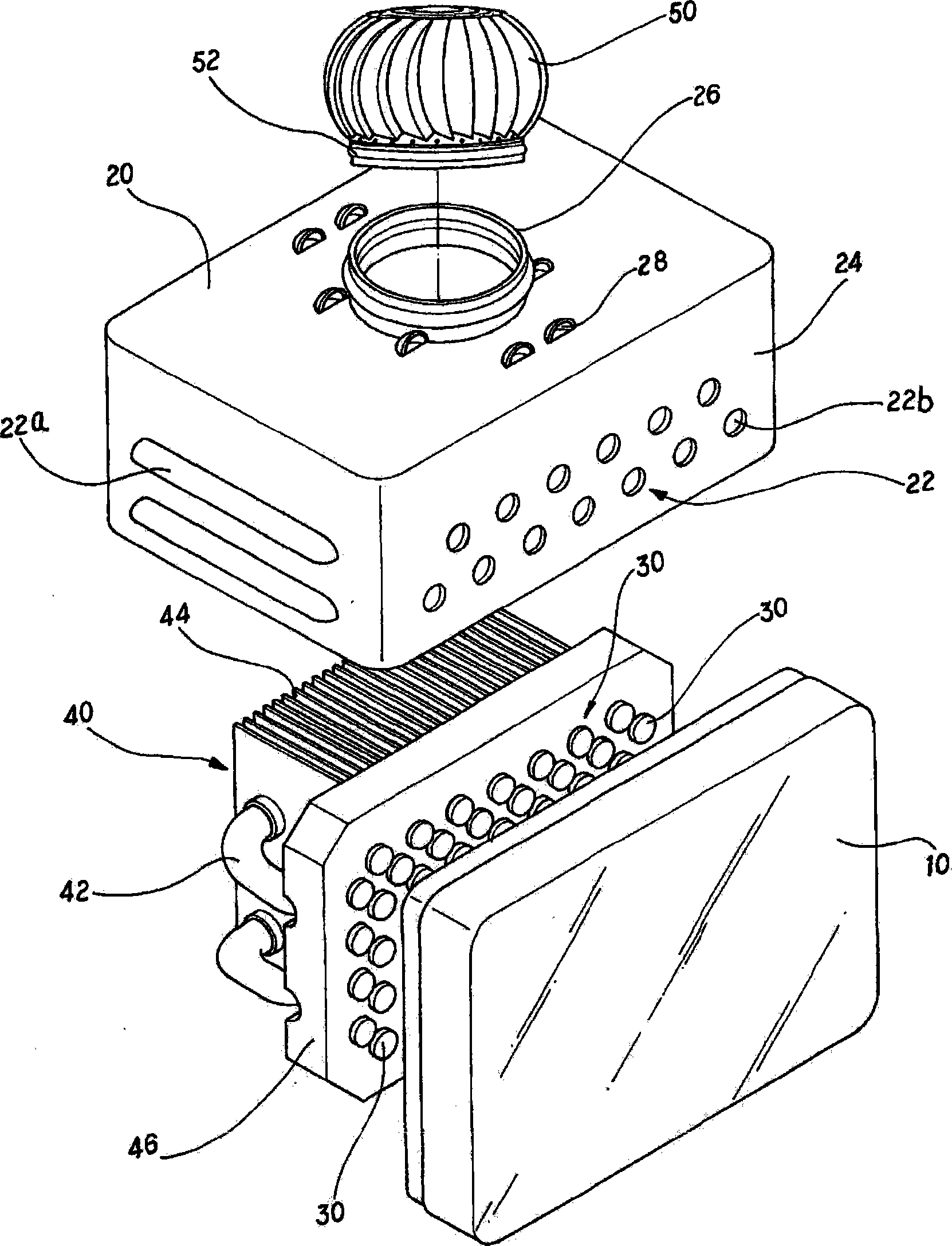

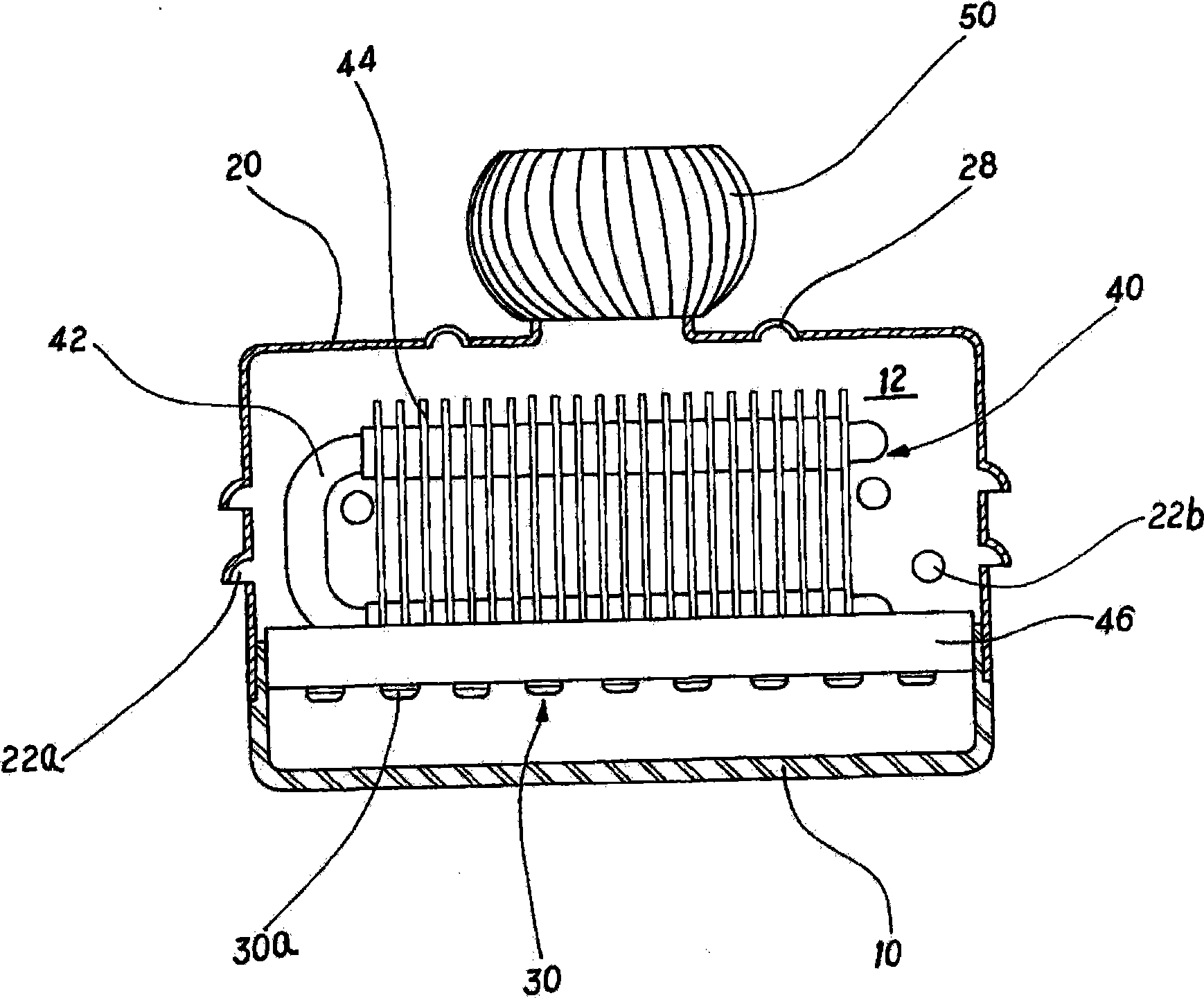

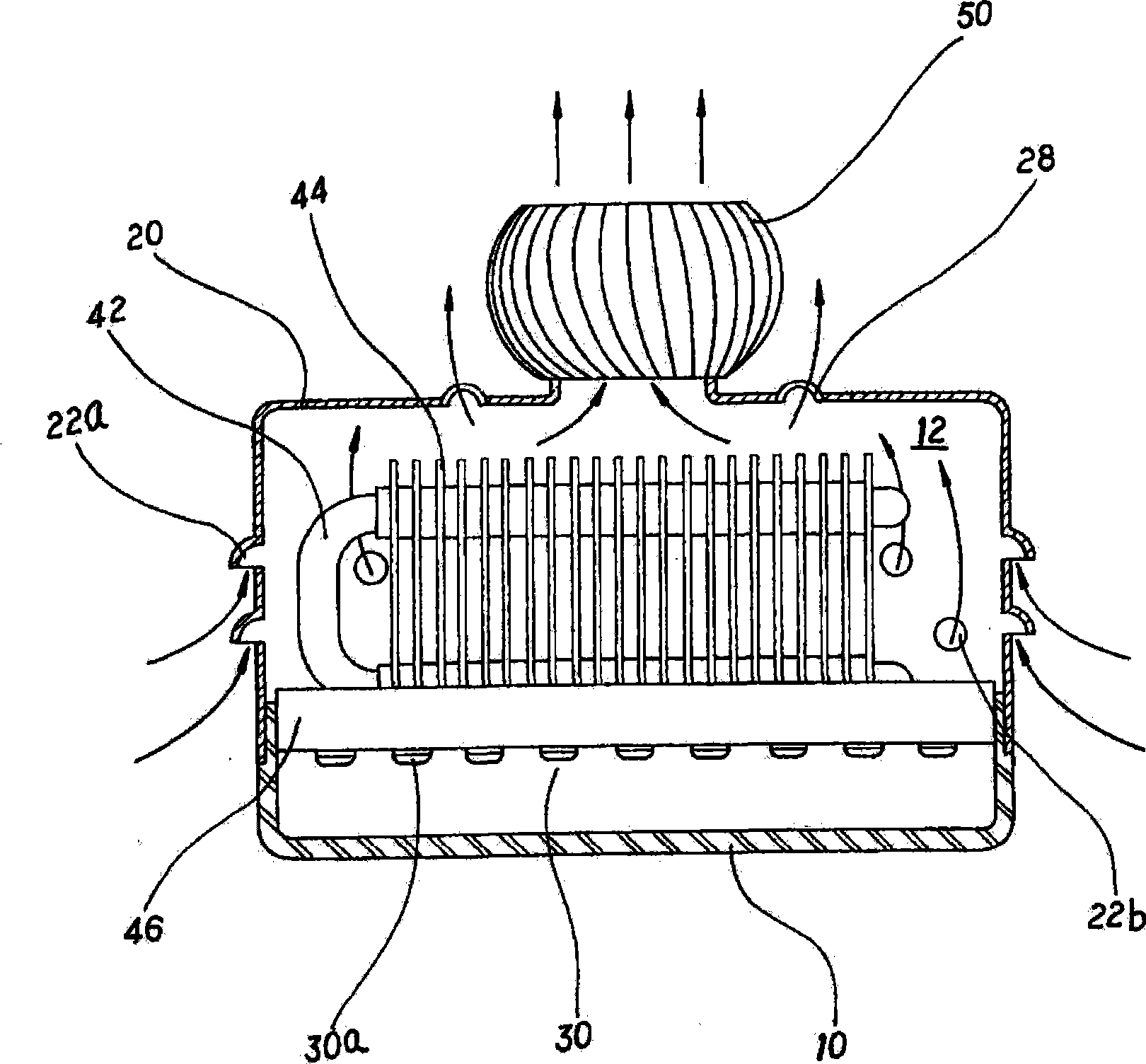

[0030] see figure 1 As shown, the lamp of the present invention has a light cover 10, the light cover 10 is a light-transmitting material, such as: plastic or glass formed, and combined with the cover body 20 to form an internal space 12, the light cover 10 will be arranged in front of the LED module 30 to evenly project the light emitted by the LED module 30 . The heat dissipation unit 40 can conduct heat conduction (heat dissipation) to the heat energy generated by the LED module 30, and is arranged at the rear end of the LED module 30. In this embodiment, the heat dissipation unit 40 includes a combination of a heat pipe 42, a heat sink 44, and a base 46. , but not limited to this combination, aluminum extrusion can also be used to form heat sinks. The LED modules 30 can be arranged in a variety of ways. The LEDs 30a can be directly planted on the base 46 of the cooling unit 40 as shown in the figure of this embodiment, or the LEDs 30a can be installed on a substrate first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com