Transformer heat exchanger adopting evaporation cooling technique

A technology of evaporative cooling and heat exchanger, which is applied in the direction of transformer/inductor cooling, indirect heat exchanger, lighting and heating equipment, etc. It can solve the problems of low cooling efficiency, limitation, leakage of water-cooled cooler, etc., and avoid water-cooled Effects of cooler and air-cooled cooler, reduction in size and weight, and improvement in operational reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

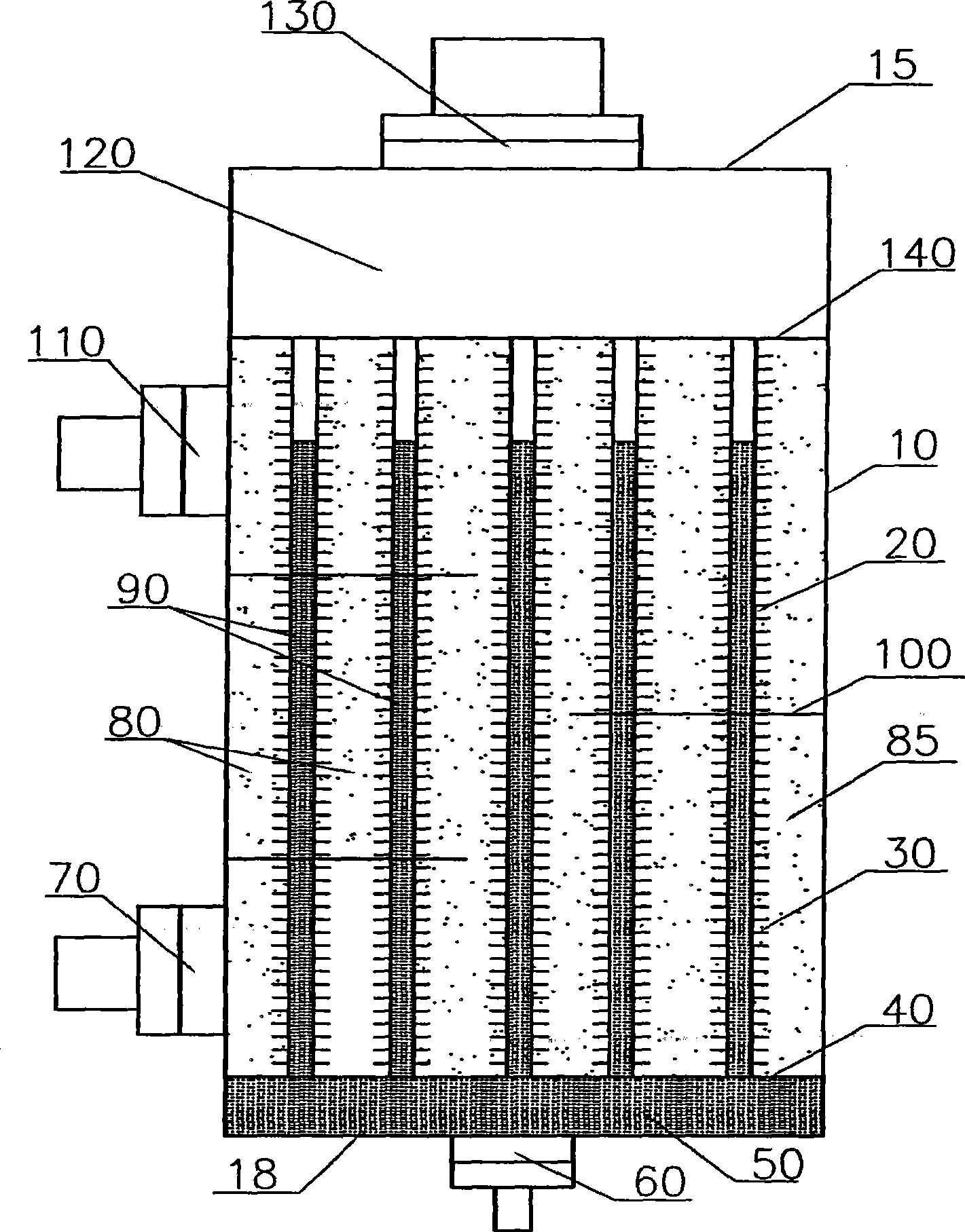

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0026] As shown in the drawings, the specific embodiment of the present invention consists of a sealed container shell wall 10, an upper top plate 15 of the sealed container, a lower bottom plate 18 of the sealed container, metal heat exchange tubes 20, tube fins 30, an oil-liquid separation bottom plate 40, and a liquid collection space. 50. Liquid inlet flange 60, oil outlet flange 70, transformer oil 80, oil chamber 85, evaporation liquid 90, tube side baffle 100, oil inlet flange 110, gas collection space 120, gas outlet flange 130, oil Separate the top plate 140 and other components.

[0027] The sealed container shell wall 10, the upper top plate 15 of the sealed container and the lower bottom plate 18 of the sealed container form the whole shell of the sealed container. A liquid collection space 50 is formed between the lower bottom pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com