Wiring box

A junction box and box cover technology, which is applied in the field of junction boxes, can solve problems such as the temperature rise of the metal connector group, the increase in the cost of the junction box, and the complex structure of the heat dissipation metal sheet.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

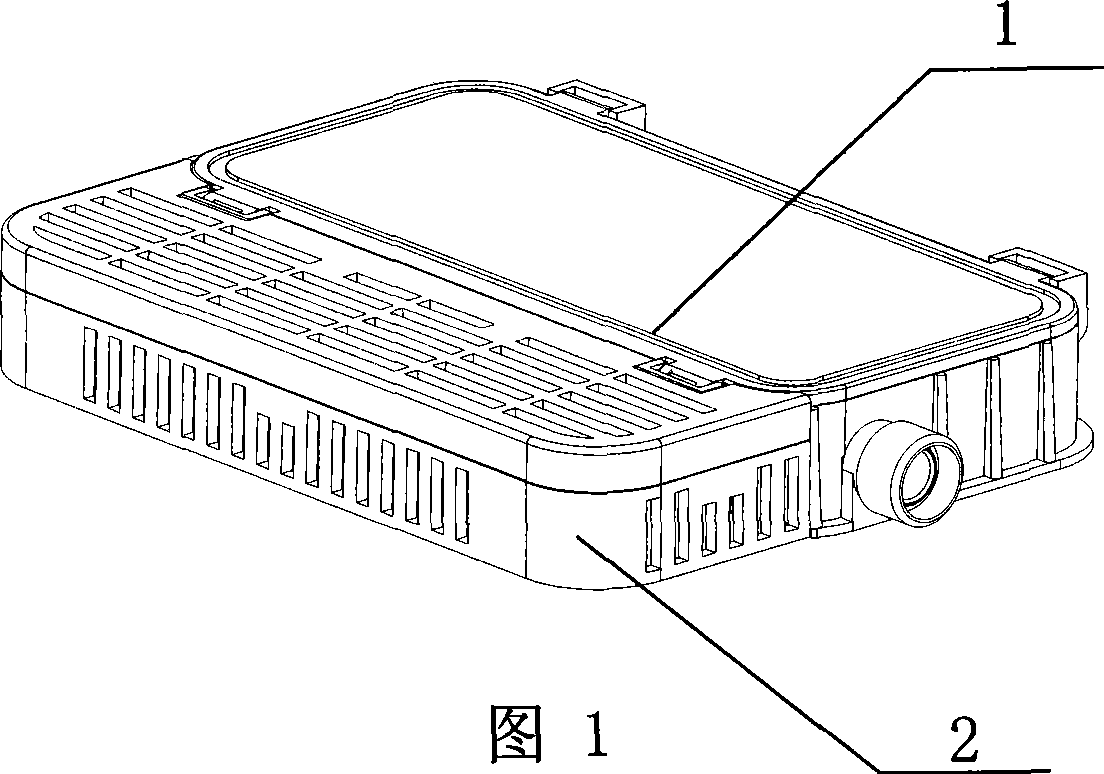

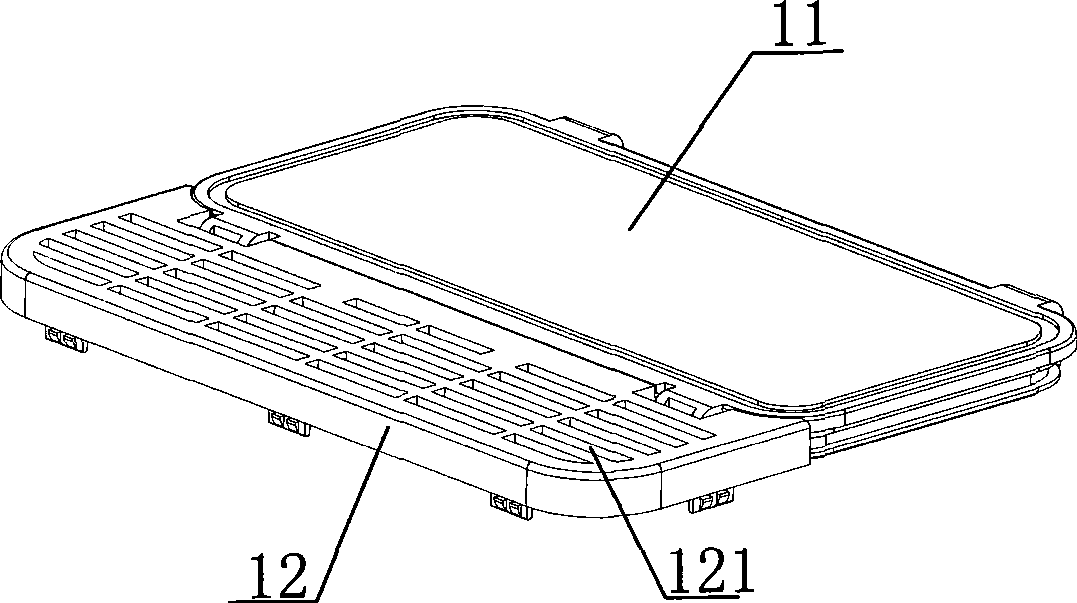

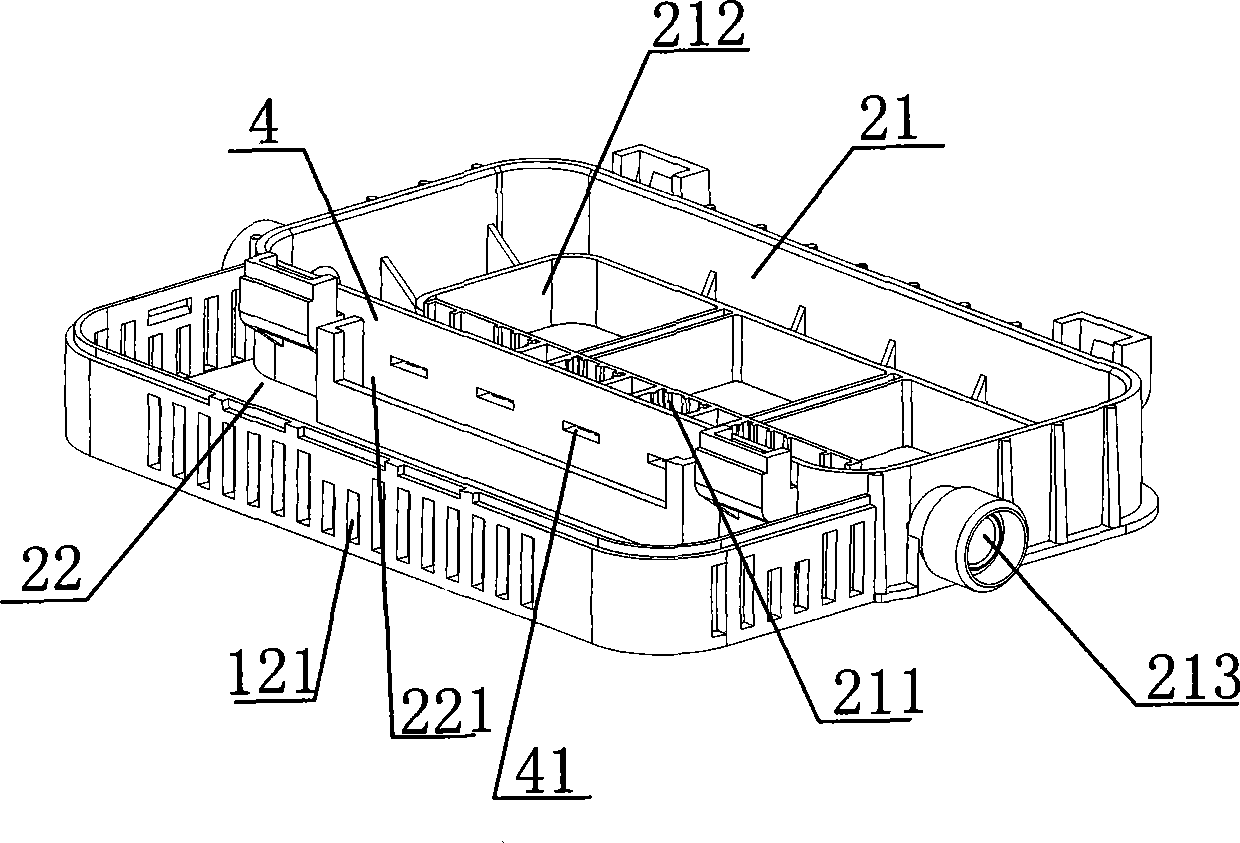

[0024] This embodiment relates to a junction box, which includes a box cover 1, a box body 2, and several parallel metal connectors 3. The box body 2 is divided into two chambers by a partition 4, which are respectively a closed chamber 21 and a heat dissipation chamber 22. A plurality of mounting grooves 211 are arranged side by side in the airtight chamber 21 close to the side of the partition 4, and the metal connector 3 is embedded in the installation groove 211. The bottom surface of the airtight chamber 21 away from the side of the partition 4 is provided with a hole 212. On the partition 4 There are two holes 41 corresponding to the metal connector 3; the box cover 1 is two, respectively an airtight cover 11 and a heat dissipation cover 12, which are matched with the corresponding airtight chamber 21 and heat dissipation chamber 22, and the sides of the heat dissipation chamber 22 or The heat dissipation cover 12 is provided with a heat dissipation hole 121 . The heat d...

Embodiment 2

[0027] Embodiment 2 is a further improvement on Embodiment 1. The improvement is that a glue injection groove 221 is provided in the cooling cavity 22 near the partition 4 along the length direction of the partition 4 .

[0028] The function of setting the glue injection groove 221 is to inject waterproof glue into the glue injection groove 221 when the diode template 5 is placed in the heat dissipation cavity 22 and passes through the hole 41 on the partition plate 4 to connect with the metal connector 3, and the hole 41 is airtight, which not only plays a waterproof role but also makes the diode template 5 and the metal connector 3 fully airtight.

Embodiment 3

[0030] Embodiment 3 is further improved on the basis of Embodiment 1. The improvement is that the outermost metal connector 3 is connected with a round tubular metal terminal 34, and the closed cavity 21 in the extending direction of the circular tubular metal terminal 34 is Wiring holes 213 are provided on the side. With this scheme, the distance from the connecting wire to the circular tubular metal terminal 34 is the shortest, and the connecting wire can be inserted into the circular tube during connection, making the connection more convenient and firm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com