Heating power direct drinking machine/water boiling machine/water heater

A technology of boiling water machine and direct drinking machine, applied in beverage preparation devices, household appliances, applications, etc., can solve the problems of energy waste, secondary pollution, increase initial investment, etc., to avoid repeated investment, increase production, and reduce energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

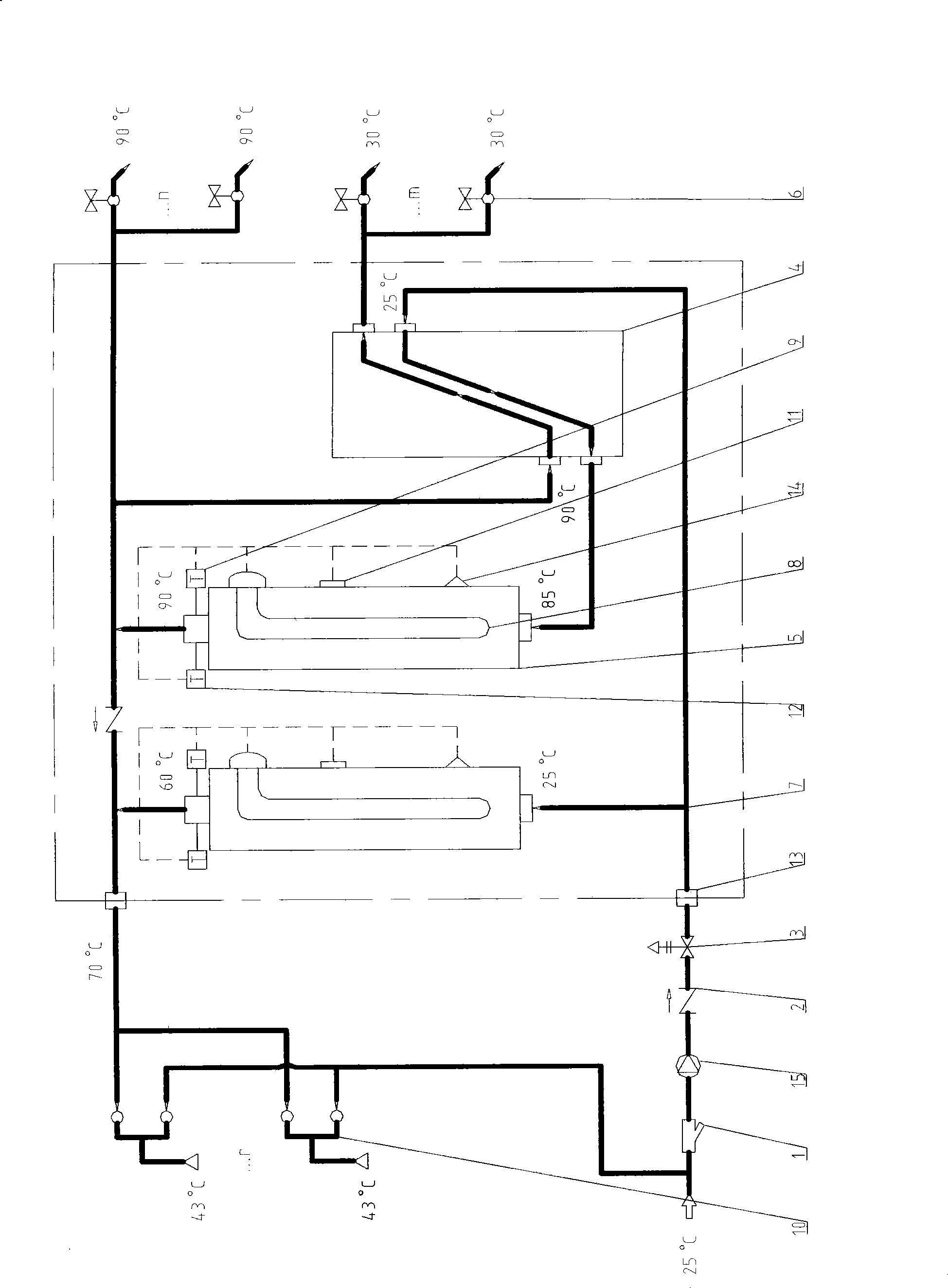

[0062] Embodiments of the thermal direct drinking machine / boiling water machine / water heater proposed by the present invention are attached figure 1 As shown, the description is as follows: It consists of DN15 outer wire stainless steel angle valve, DN15 inner wire stainless steel protective impurity filter 1 and DN15 inner wire stainless steel activated carbon filter 1, DN15 inner wire stainless steel check valve 2 and drain Pressure valve 3, DN15 inner wire anti-electricity isolation wall 13, heat exchange area 0.315m 2 The 316 stainless steel plate type thermal insulation regenerator 4 on the water side, the 304 stainless steel thermal insulation tank 5 with a diameter of 140mm and a height of 800mm, the drinking water side of the thermal insulation regenerator 4, 2 parallel DN15 inner wire stainless steel drinking water ball valves 6 and its diameter 15mm stainless steel connection The pipeline and two DN15 inner wire stainless steel tees 7, etc., form a thermal direct dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com