Fine particle preparation device using supercritical fluid quick expansion

A technology of supercritical fluid and fine particles, applied in the direction of solution crystallization, etc., can solve the problems of unstable pressure of decompression precipitation device, failure to meet process quality requirements, uneven particle size of ejected matter, etc., and achieve extended drying time, dry Good effect and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

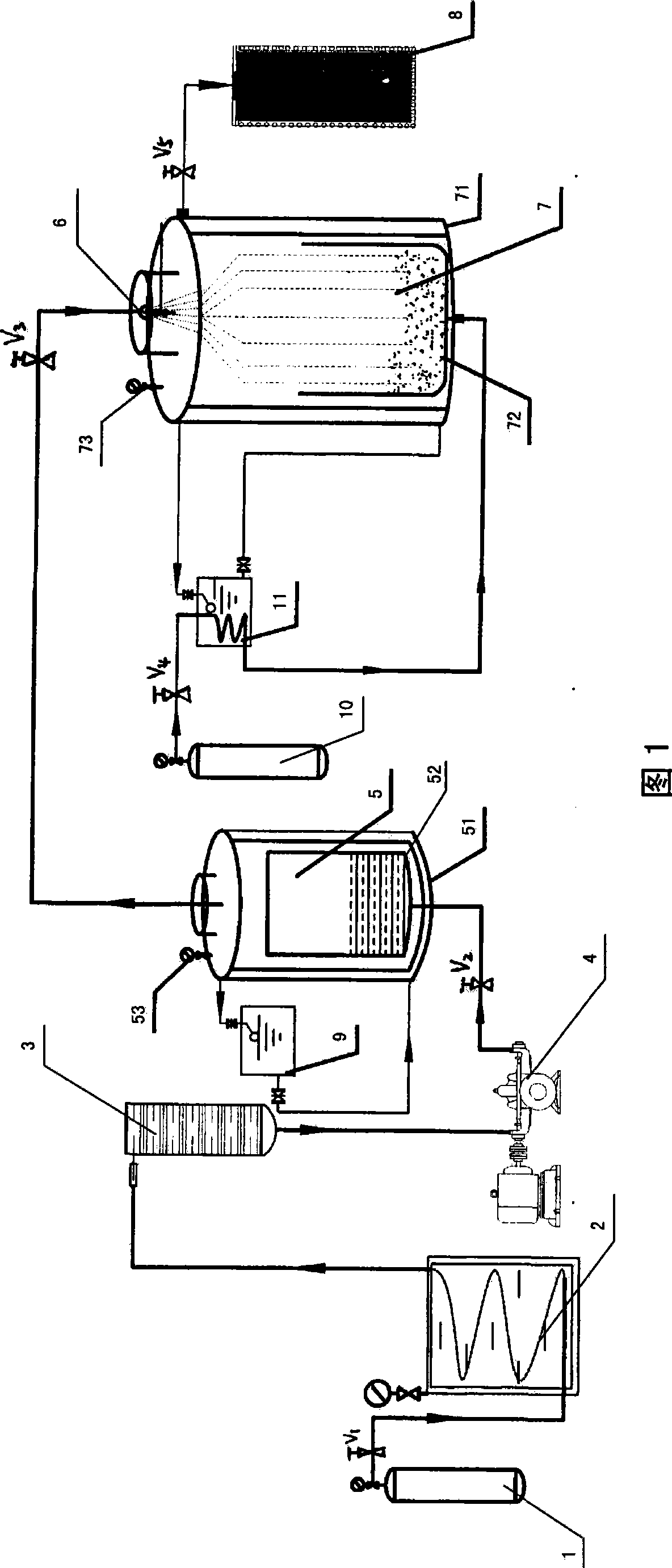

[0027] As shown in Figure 1, the structure of the supercritical fluid rapid expansion of the present invention to prepare the microparticle device embodiment is composed of CO 2 Solvent bottle 1, condensing compressor 2, solvent storage tank 3, high-pressure pump 4, extraction kettle 5, nozzle 6, crystallization kettle 7, exhaust and collection device 8 and several adjustment control valves; condensing compressor 2 and solvent storage tank 3 constitute a refrigeration unit; said extraction kettle 5 is covered with a water tank jacket 51, the water tank jacket 51 is connected with a constant temperature water tank 9, the water in the constant temperature water tank 9 and the water tank jacket 51 circulates through the circulation pump, and the water tank jacket 51 is installed in the extraction kettle There is a stainless steel material cylinder 52, and an electric contact pressure gauge 53 is also provided on the extraction kettle; the crystallization kettle 7 is covered with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com