Square cone bottom spraying pot

A cone-bottomed, square-shaped technology, used in digesters, textiles and papermaking, fiber raw material processing, etc., can solve problems such as many failures and easy blockage, and achieve the effects of saving investment costs, eliminating deposits and blockages, and saving energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

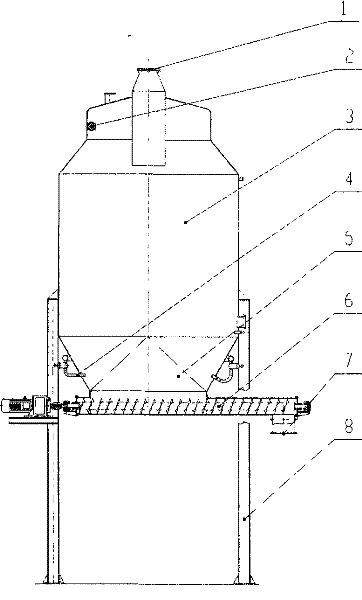

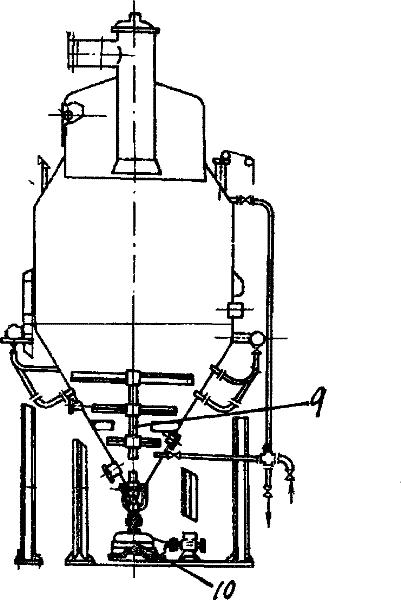

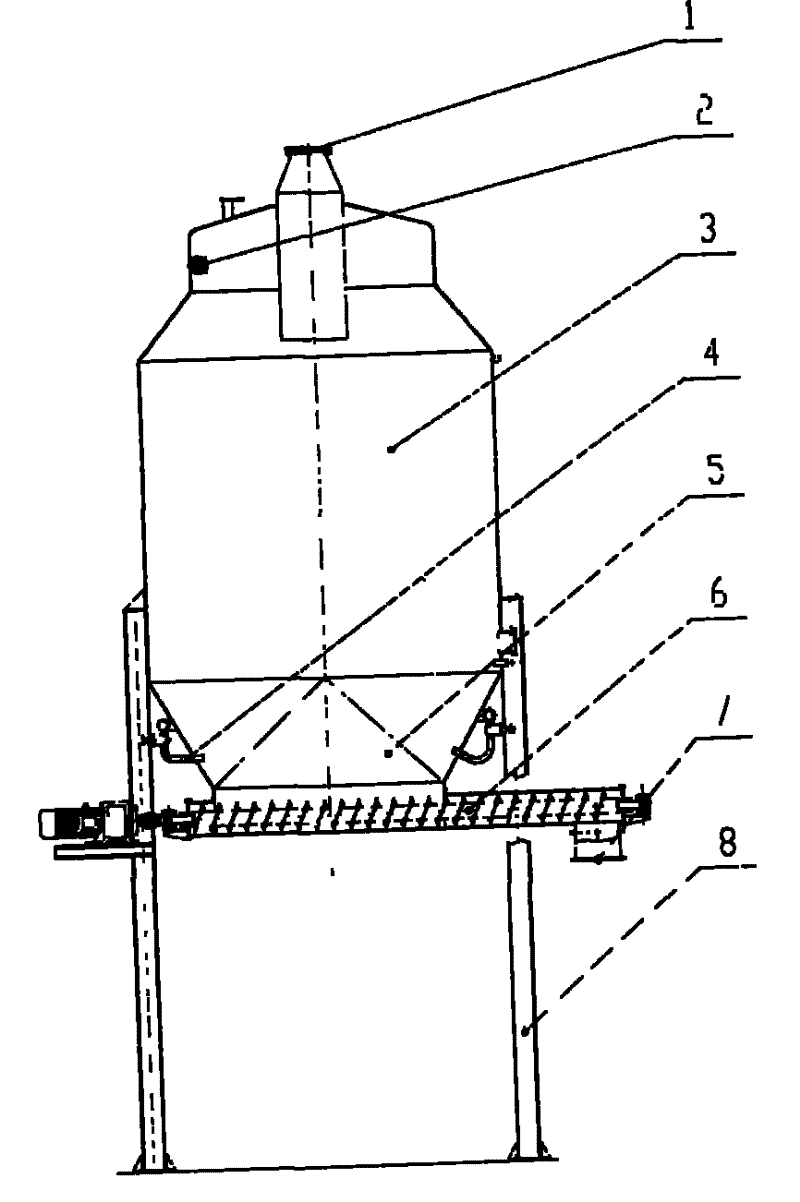

[0011] Such as figure 1 As shown, the present invention is mainly made up of pot body 3, square conical bottom 5, screw discharger 6, and pot body and square conical bottom are combined to form a conical bottom structure at the bottom of the upper circle. Ground installation, screw feeder 6 is horizontally placed at the bottom of square conical bottom 5, forms a unified assembly with spray pot. The screw discharger 6 is a closed cylindrical structure, and its square inlet is directly connected with the square cone outlet at the bottom of the cone. The top of the spraying pot is provided with an exhaust port 1 and a spraying pipe interface 2, and liquid feeding nozzles are arranged around the square cone bottom.

[0012] When working, the slurry of the continuous digester is continuously sprayed into the spray pot through the discharge port, and the induction inner cylinder in the pot guides the slurry to spin down along the inner wall of the pot and fall into the bottom of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com