Mobile bitumen regenerated heat mixing device

A kind of asphalt regeneration and mobile technology, which is applied in roads, road repairs, roads, etc., can solve problems that affect road performance and driving safety, diseases cannot be treated in time, and equipment production capacity is large, and achieve simple structure, reliable performance, good mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with embodiment.

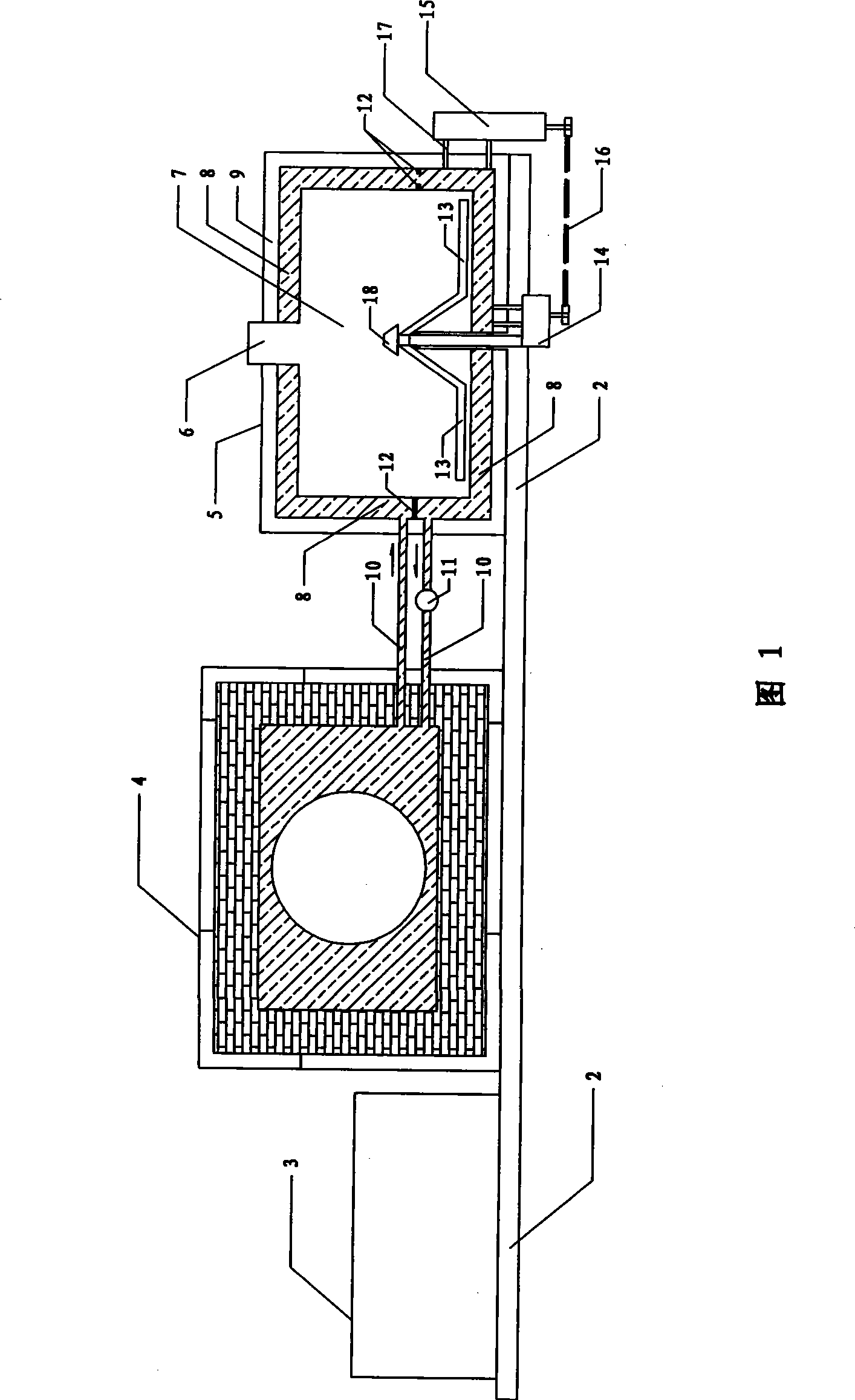

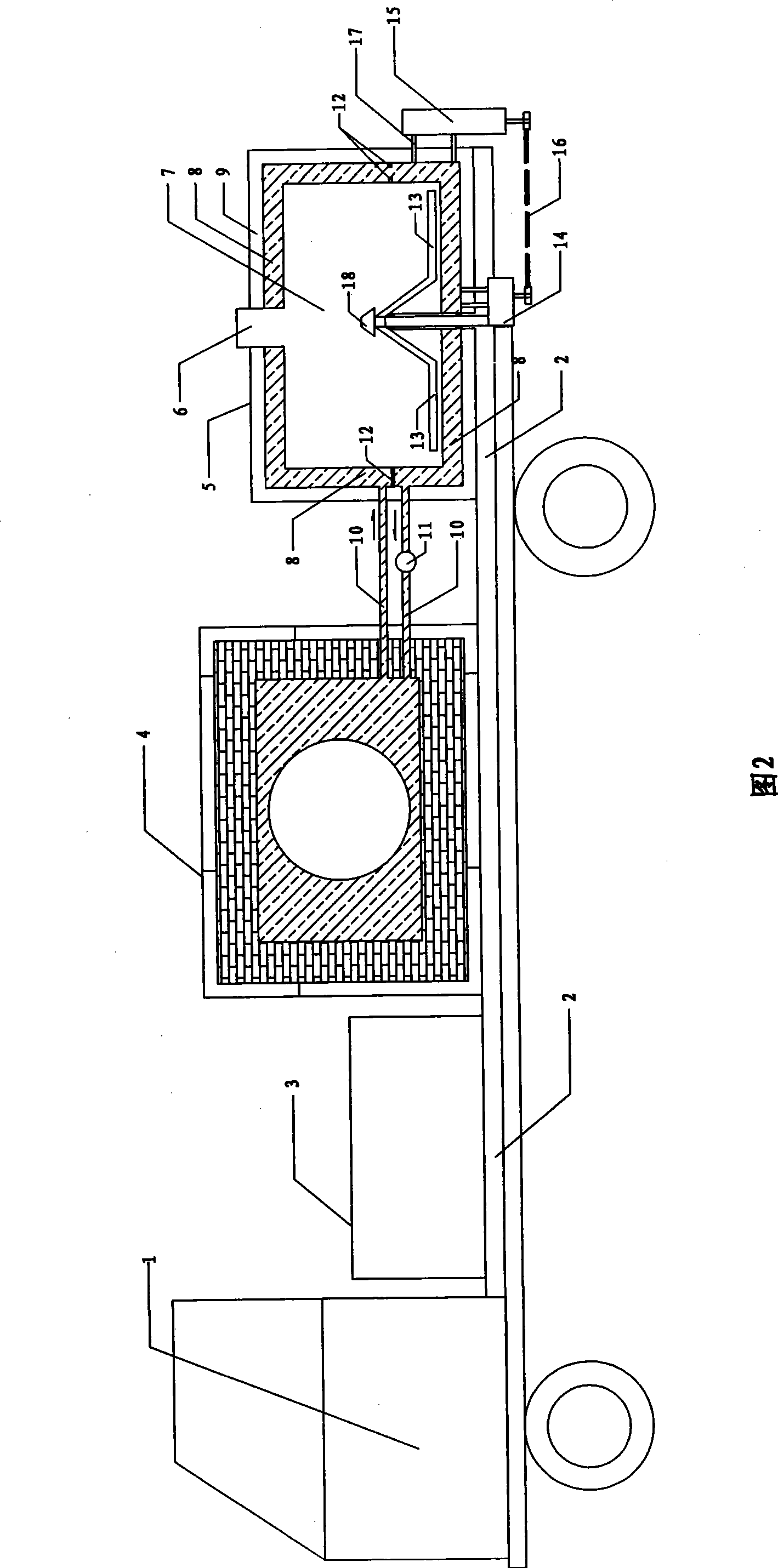

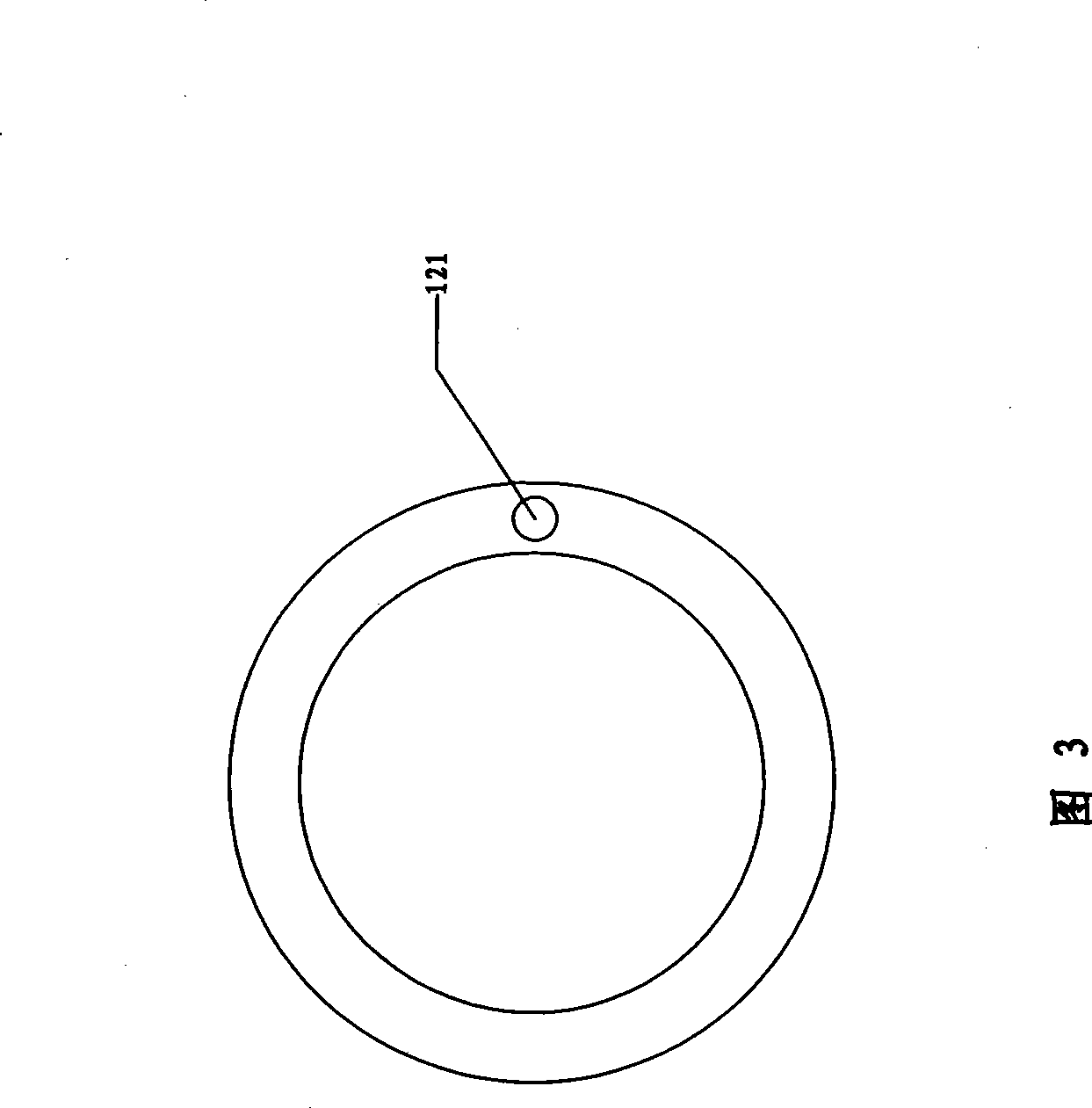

[0014] As shown in Figure 1, the mobile asphalt regeneration hot mixing equipment includes a base 2, a generator set 3, an organic heat carrier furnace 4, and a mixing pot 5, and the generator set, an organic heat carrier boiler, and a mixing pot are fixed on the base 2. The structure of the mixing pot is a mixing chamber 7, a heat transfer oil layer 8 and an insulation layer 9 from the inside to the outside, and the insulation layer is located outside the heat transfer oil layer to avoid heat loss. The mixing pot has a feed port and a discharge port, the feed port 6 is located above the stir pot, and the discharge port is located below the side of the stir pot. The heat-conducting oil layer 8 of the mixing pot is connected with the heat-conducting oil boiler through a heat-conducting oil pipe 10. The heat-conducting oil pipe includes an oil inlet pipe and an oil outlet pipe, and a h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com