Half- penetration and half-reflection LCD

A semi-transmissive, semi-reflective, liquid crystal display technology, applied to static indicators, instruments, nonlinear optics, etc., can solve the problem of high cost of semi-transmissive, semi-reflective liquid crystal displays, achieve increased inclination and twist, and increase birefringence efficiency and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

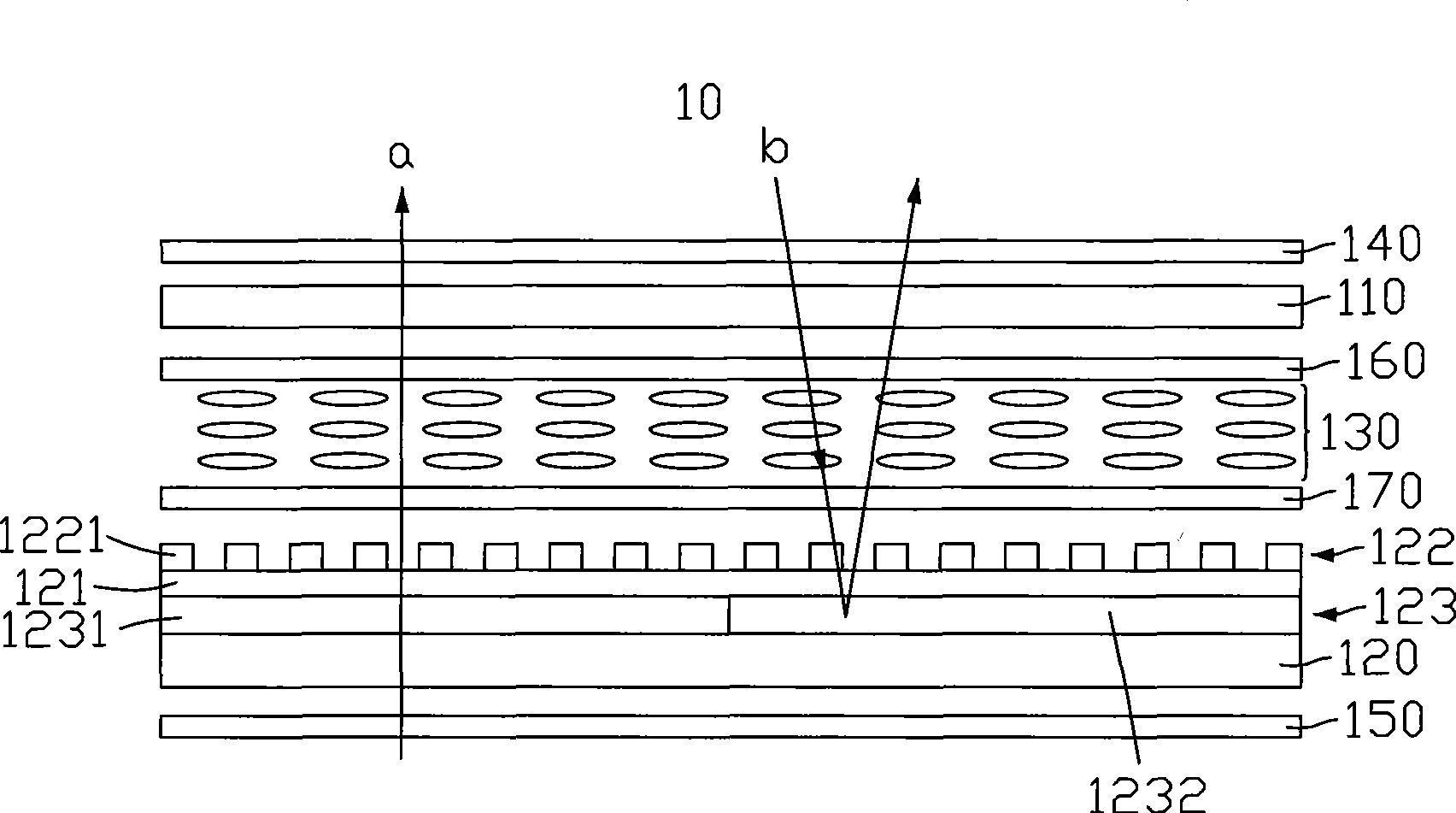

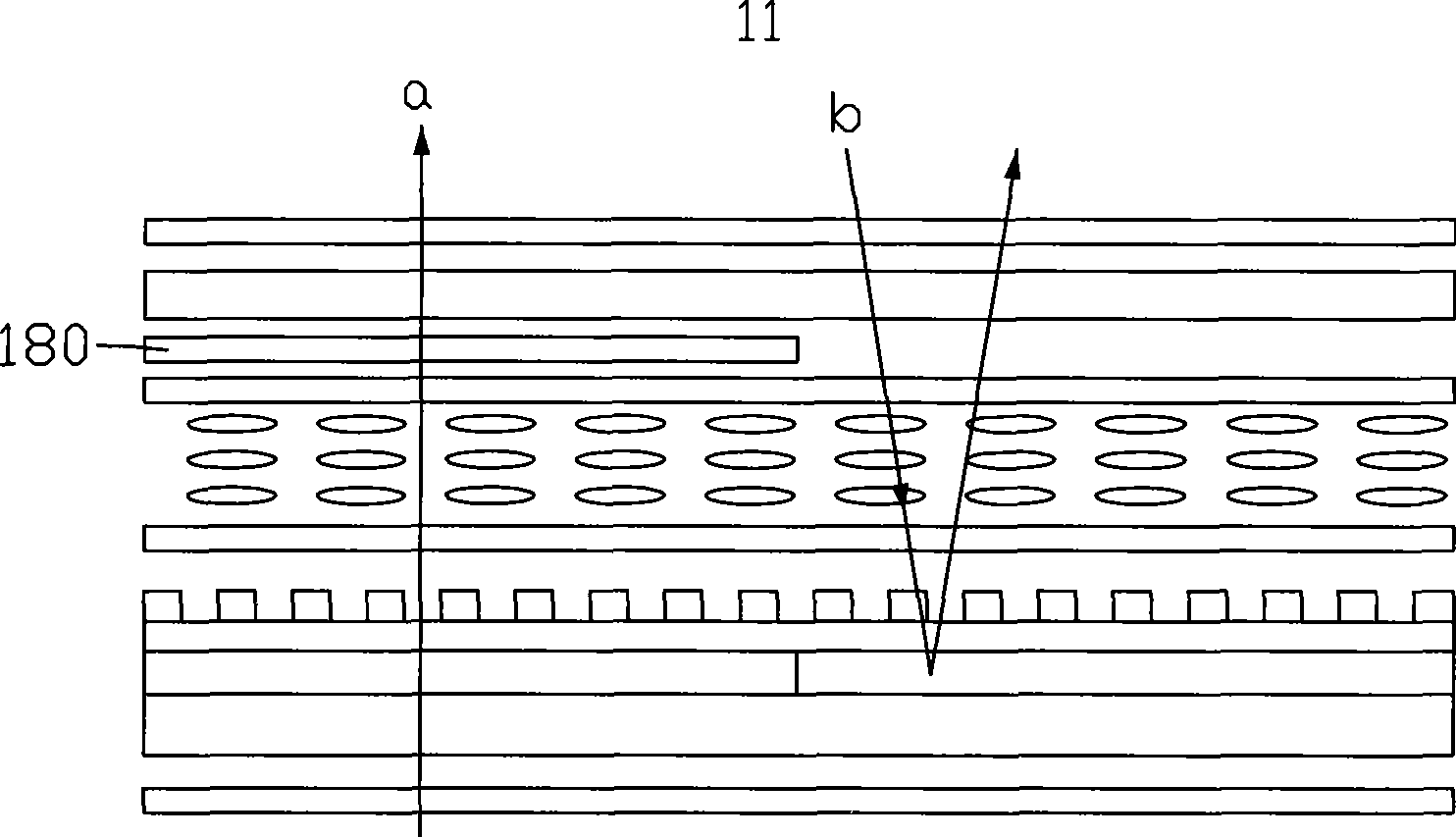

[0022] see Figure 5 , is a schematic diagram of the first embodiment of the transflective liquid crystal display of the present invention. The liquid crystal display 20 includes a first glass substrate 210, a second glass substrate 220 opposite to the first glass substrate 210, a liquid crystal layer 230 sandwiched between the two glass substrates 210, 220, a A first polarizer 240 on the outer surface of the glass substrate 210, a second polarizer 250 on the outer surface of the second glass substrate 220, a control electrode layer 280 on the inner surface of the first glass substrate 210 and a first The alignment layer 260 , a common electrode layer 223 , an insulating layer 221 , a pixel electrode layer 222 and a second alignment layer 270 are sequentially located on the inner surface of the second glass substrate 220 .

[0023] The common electrode layer 223 includes a transmissive region 2231 and a reflective region 2232 . The control electrode layer 280 is located on t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com