Pixel, pixel module and liquid-crystal display panel

A liquid crystal display panel, pixel technology, applied in static indicators, nonlinear optics, instruments, etc., can solve problems such as difficult to drive pixels, and achieve the effect of reducing the total number of source/gate channels and reducing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

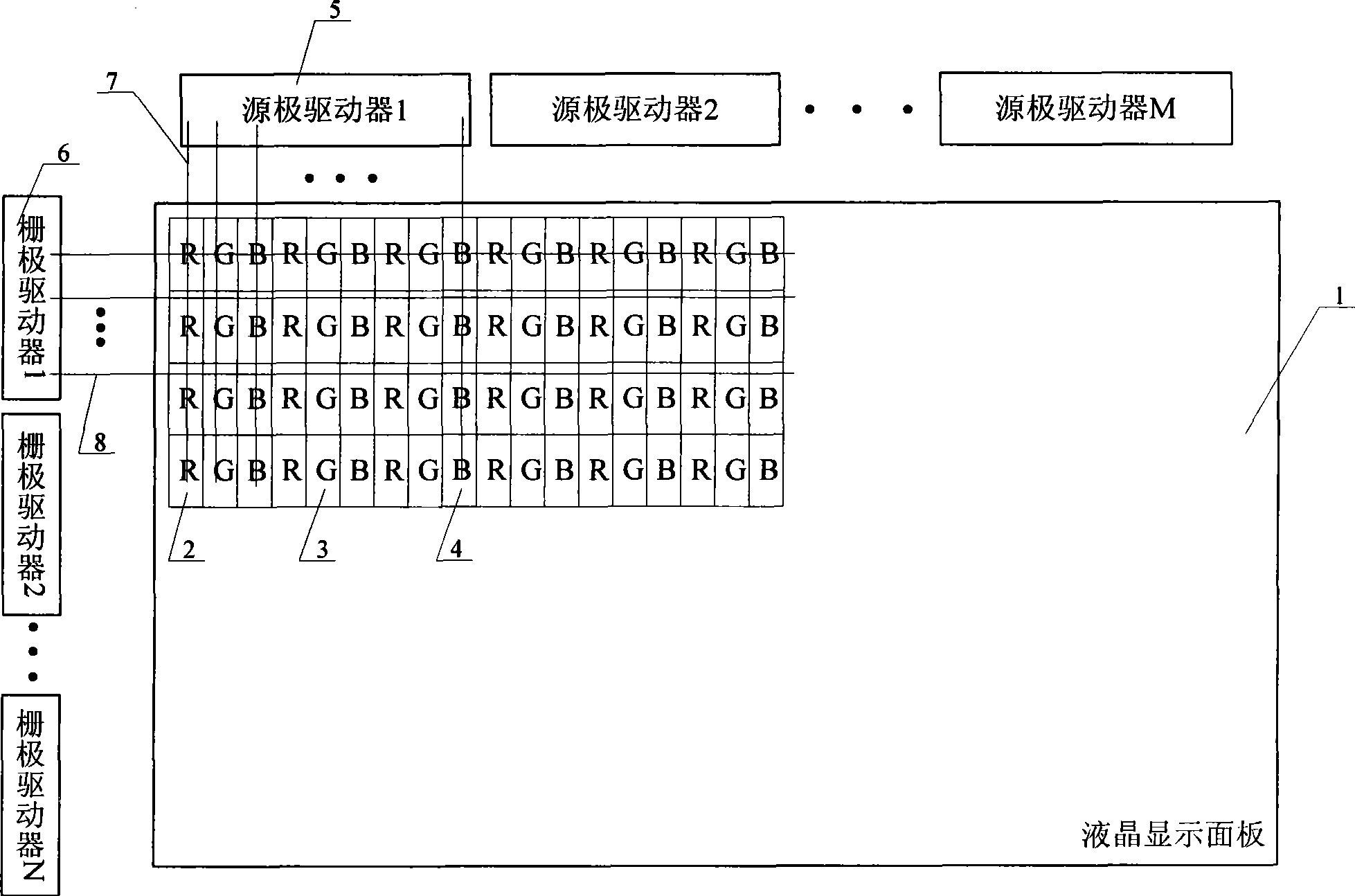

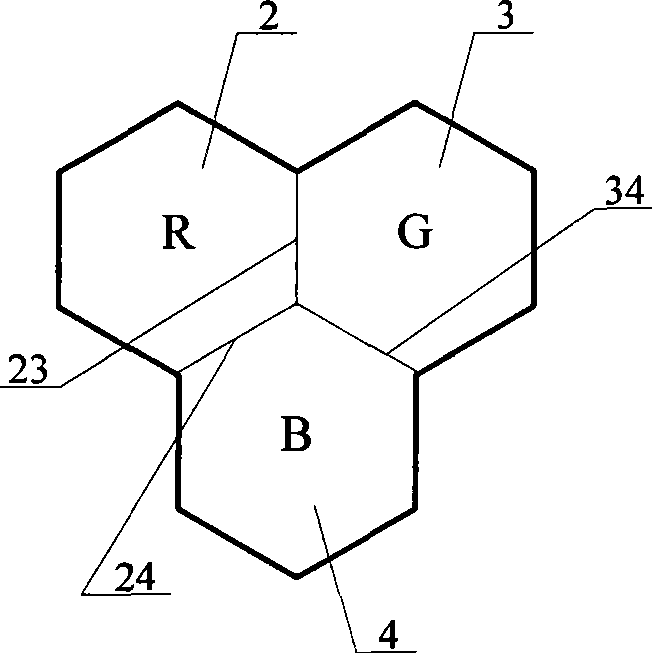

[0028] Such as Figure 3A Shown is the arrangement structure of multiple pixels on the liquid crystal display panel in this embodiment. The central connection lines of the three sub-pixels are arranged in an equilateral triangle. There is no pixel of the same color as the pixel among the six adjacent sub-pixels around the pixel. Such as Figure 3A As shown in , the six sub-pixels adjacent to each side of the sub-pixel R2′ are respectively arranged at intervals of G sub-pixels and B sub-pixels; for the sub-pixels at the edge of the liquid crystal display panel 1, such as R 2", the two sides of which are not shown adjacent to the sub-pixel are respectively adjacent to the G sub-pixel 101 and the B sub-pixel 102 corresponding to the bottom side. Figure 3A The first row where the pixels 9 and 10 are located, the second row where the pixels 11 and 12 are located, and so on, the pixels of the honeycomb distribution are arranged in a 6 (column) × 4 (row) dot matrix; Figure 3B Th...

Embodiment 2

[0030] In the embodiment of the present invention, the direction in which the central lines of sub-pixels are connected in a straight line is the horizontal direction of the pixel module, such as Figure 4A Middle gate channel 8 is connected to the pixel direction or Figure 4B The middle source channel 7 is connected to the pixel direction; the direction in which the center line of the sub-pixel is zigzag connected is the longitudinal direction of the pixel module, such as Figure 4A The source channel 7 is connected in the pixel direction or as Figure 4B The middle gate channel 8 is connected to the pixel direction.

[0031] Such as Figure 4AAs shown, the pixel modules adopt the arrangement described in the above-mentioned embodiment 1, and it is defined that the central connection line of the sub-pixel is connected in a straight line as the horizontal direction of the pixel module, such as the direction of the gate channel 8 connecting the pixel; the central connection ...

Embodiment 3

[0033] Such as Figure 4B As shown, the pixel module adopts the arrangement described in the above-mentioned embodiment 1, and defines that the center line of the sub-pixel is connected in a straight line as the horizontal direction of the pixel module, such as the source channel 7 connecting the pixel direction; the center line of the sub-pixel is in the direction of The zigzag connection is the longitudinal direction of the pixel module, for example, the gate channel 8 is connected to the pixel direction. Horizontally, the sub-pixels whose center line is on the same straight line share one source channel 7; vertically, each of the sub-pixels on the same lateral edge shares one gate channel 8, except for the edges, the sub-pixels Connected in sequence, the sub-pixels on each connection share a gate channel 8, and connected in sequence: the center connection of the sub-pixel is the same shape as the center connection of the sub-pixels on both sides of the edge, such as Figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com