Highly explosion preventing wane type switch

A rocker and switch technology, applied in electrical switches, electrical components, circuits, etc., can solve the problems of large size, poor reliability, and complex seal design of explosion-proof switches, and achieve small size, light action, and is conducive to arc extinguishing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

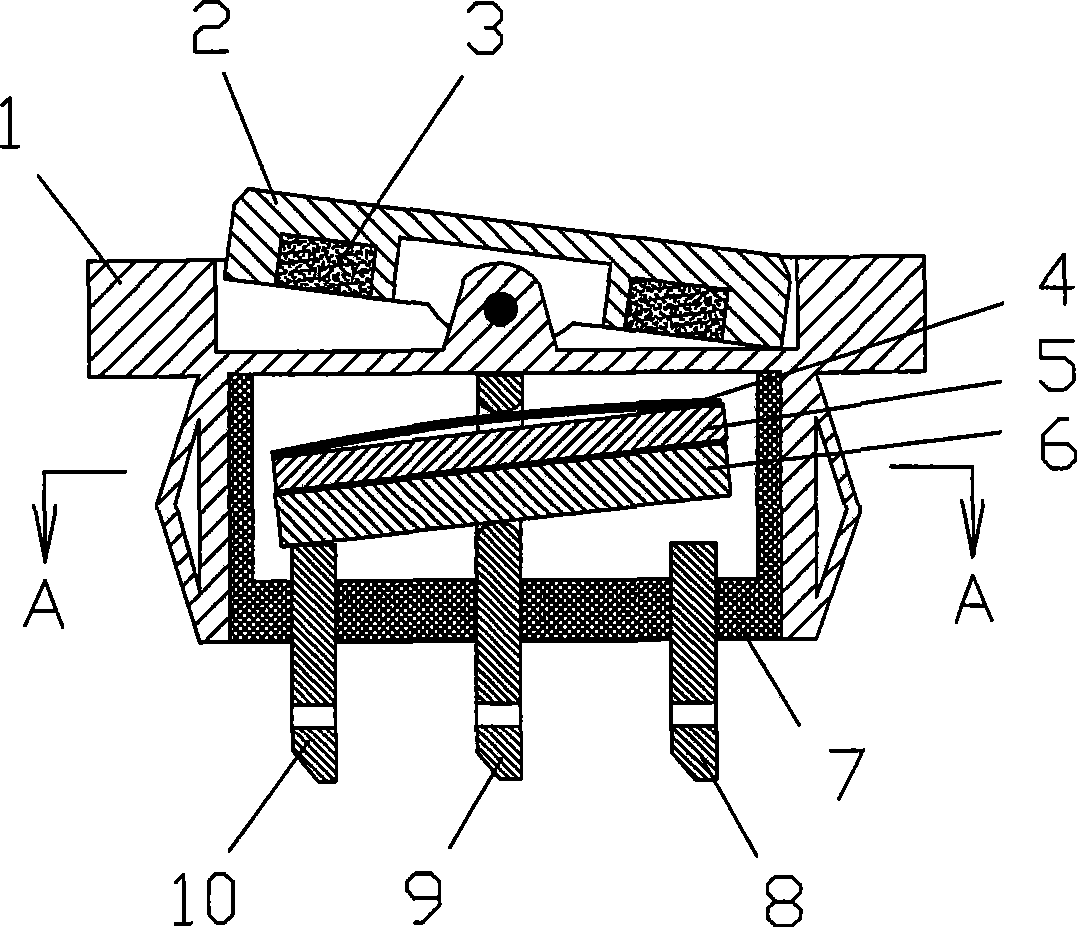

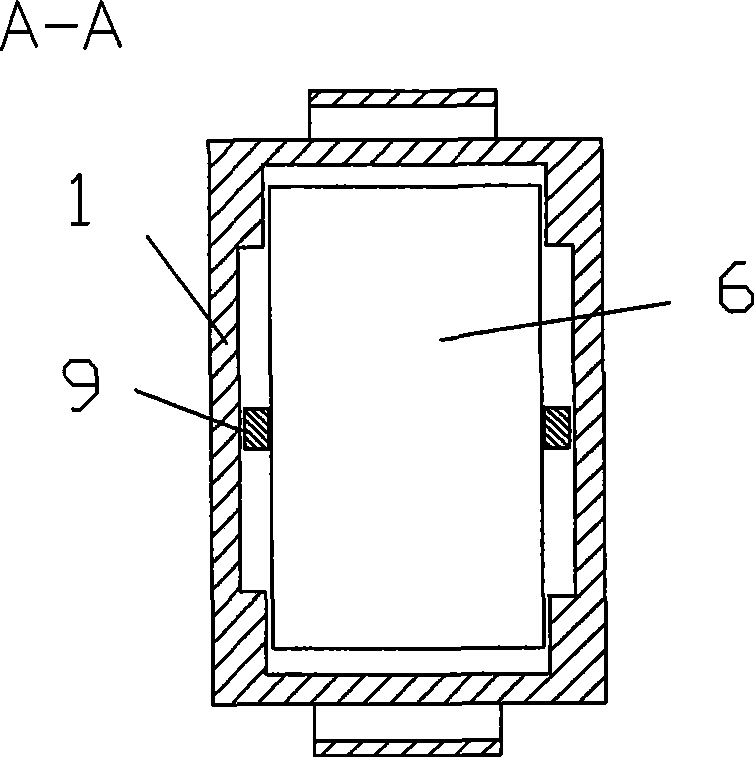

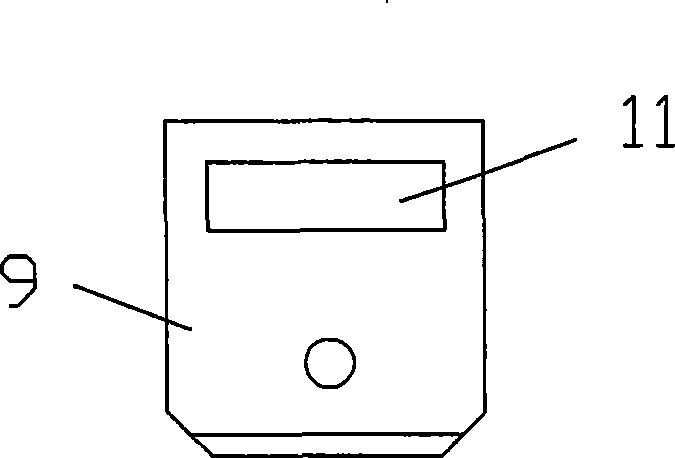

[0013] For the switch structure of the embodiment, see figure 1 with figure 2 , The selection of the on-off of the circuit is completed by the left contact piece 10, the right contact piece 8, the middle contact piece 9, and the moving contact piece 6. The moving contact piece 6 is placed on the middle contact piece 9 and can be tilted left and right. When the moving contact piece 6 When the left contact piece 10 is in contact, the left side is energized; when the moving contact piece 6 and the right contact piece 8 are in contact, the right side is energized.

[0014] The above-mentioned left contact piece 10, right contact piece 8, middle contact piece 9, and moving contact piece 6 are all in the switch chamber 7. The upper opening of the switch chamber 7 is sealed with the panel of the housing 1 to form a closed structure.

[0015] The panel of the shell 1 is equipped with a rocker 2, which is the operating part of the hand-operated switch, and two magnets 3 are installed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com