Ready-to-install needle bearing comprising an inner and outer ring

A technology of needle roller bearings and outer ring raceways, which is applied in the field of manufacturing needle roller bearings of the present invention, can solve the problems of difficult bearing assembly, cost hardening and grinding, etc., and achieve the effect of improving bearing capacity and small distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

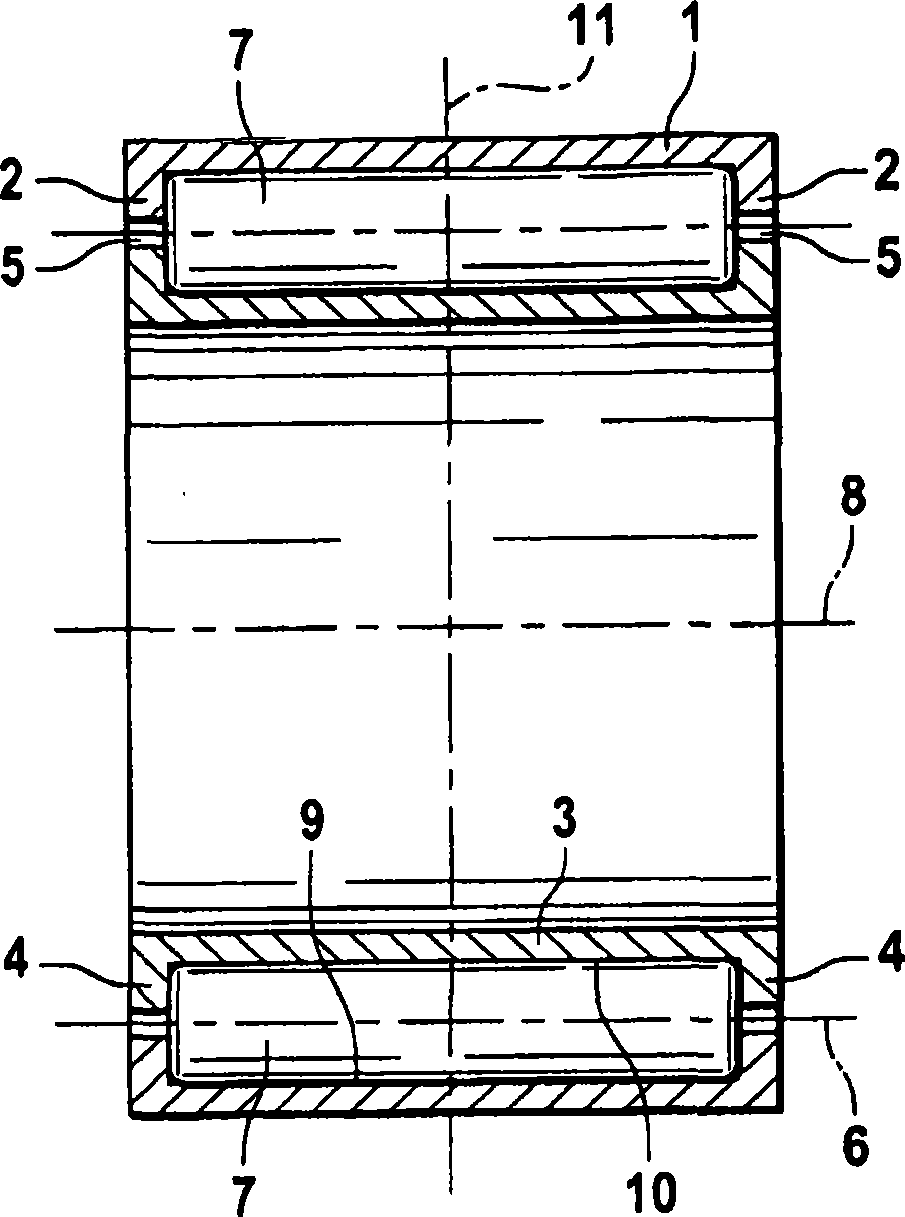

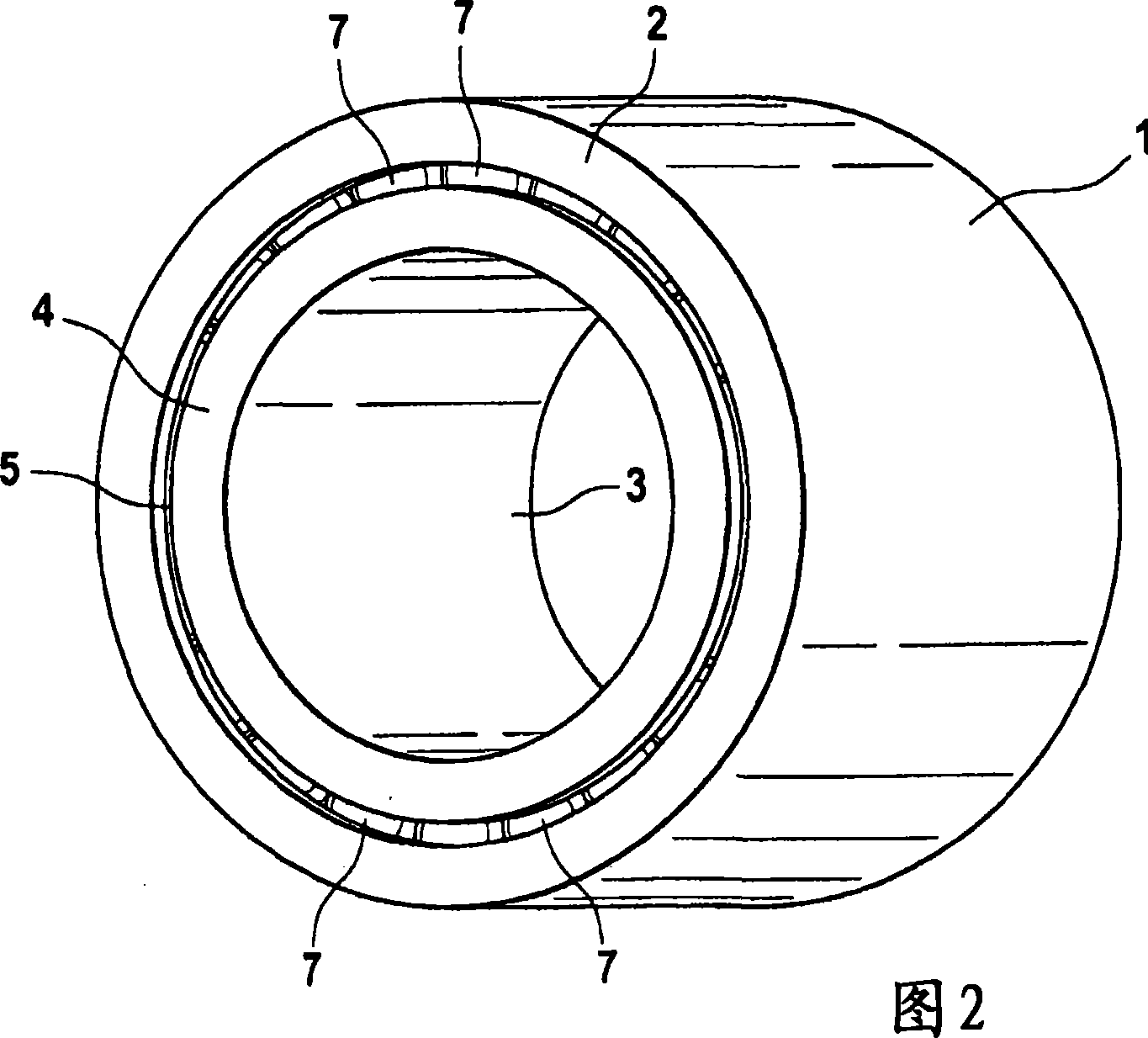

[0015] figure 1 The assembled needle roller bearing constructed according to the invention shown in and 2 comprises an outer ring 1 and an inner ring 3 which are arranged concentrically and nested within each other. Both the outer ring 1 and the inner ring 3 are provided on both sides at their axial ends with ribs 2 , 4 which are oriented radially inwardly and radially outwardly and at the same time form a surrounding annular gap 5 between them . Its radial extent can be varied by the length of the collars 2 , 4 , an advantageous sealing of the bearing being achieved with an as small as possible extent of the annular gap 5 . For this purpose, the radial extent of the collars 2, 4 is usually 25%-40% of the diameter of the needle roller 7, so that a secure axial stop is achieved. In the free space not described in more detail formed between the two rings 1, 3, a plurality of needle rollers 7 are mounted, which rotate about their own axis 6 when the bearing rotates about the ax...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com