Linear drive with a reduced axial force component, as well as a linear compressor and refrigerator

A linear compressor, linear drive technology, applied in the direction of electromechanical devices, electric components, magnetic circuit shape/style/structure, etc., can solve the problem that the back and forth motion cannot be controlled according to the required precision, the moving parts are difficult to drive, and the braking energy system Loss and other problems, to achieve the effect of easy control, reduced asymmetry, precise and efficient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

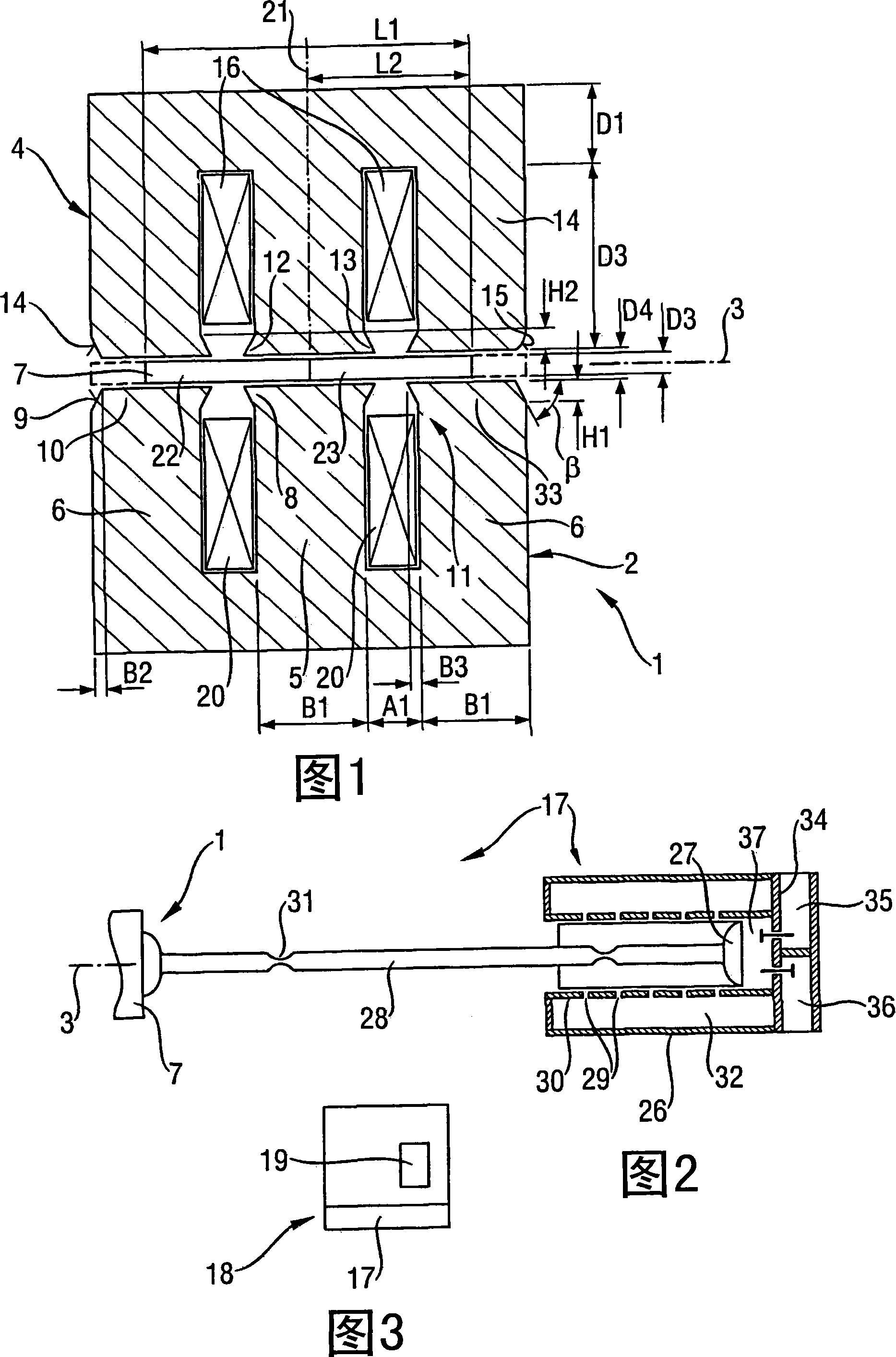

[0059] 1 shows a longitudinal section of a linear drive 1 according to the invention along the axis of motion 3 and along the coil axis 21 of the excitation coils 16 , 20 on the stator 2 . The linear drive 1 has a stator 2 and a moving part 7, and the moving part 7 moves oscillatingly back and forth along the axis 3 between two opposing points. The stator 2 has a magnetic field guiding core 4 with an inner leg 5 and two outer legs 6 each having a respective foot 8 , 33 extending approximately toward the moving part 7 . The inner foot 8 is arranged on the inner leg 5 and the outer foot 10 , 33 is arranged on the outer leg 6 . The feet 8 , 10 , 33 have inclined surfaces 9 and / or projections 12 , 13 . The inclined surface 9 can be implemented as a flat surface 14 or as a convexly curved surface 15 . The inner foot 8 has a first lug 12 and a second lug 13 each facing the adjacent outer foot 10 , 33 . The projections 12 , 13 are trapezoidal in longitudinal section along the axis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com