High-sealing aluminum foil-plastic-aluminum foil

A tropical-type blister aluminum, high-sealing technology, applied in the field of packaging materials, can solve the problems of poor tensile properties of aluminum, uneven surface gloss, monotonous color, etc., and achieve excellent deep tensile properties, colorful appearance, The effect of extending the shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

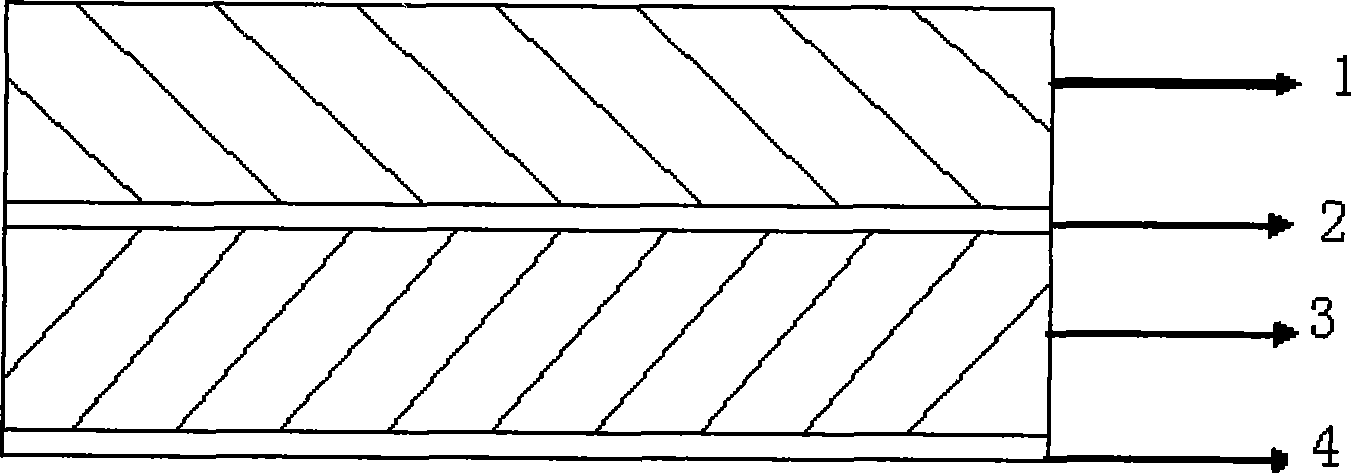

[0014] Use the nylon layer as the base layer, coat a layer of polyurethane, then bond the soft aluminum foil layer, and then coat the heat-sealing coating on the bonded soft aluminum foil layer. The thickness of the nylon layer is 15 microns, and the soft aluminum foil layer is The thickness is 75 microns.

Embodiment 2

[0016] The nylon layer is the base layer, coated with a layer of polyurethane, and then bonded with a soft aluminum foil layer, and then coated with a heat-sealing coating on the bonded soft aluminum foil layer. The thickness of the nylon layer is 25 microns, and the thickness of the soft aluminum The thickness is 60 microns.

Embodiment 3

[0018] Nylon layer 1 is the base layer, coated with a polyurethane layer, then bonded with a soft aluminum foil layer, and then coated with a heat-seal coating on the bonded soft aluminum foil layer, the thickness of the nylon layer is 30 microns, and the soft aluminum foil layer is The thickness is 45 microns.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com