Fully-automatic speed-changer of bicycle

A fully automatic, transmission technology, applied in the direction of bicycle gear shifting mechanism, bicycle accessories, vehicle transmission, etc., can solve the problems of uncoordinated components, stuck transmission transmission, and failure of transmission shifting action, etc., to achieve stable and reliable contact, The effect of avoiding action failure and easy shifting control

Inactive Publication Date: 2009-04-01

程辉

View PDF2 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

But because the back of the pawl in this kind of transmission is a completely smooth curved surface, the long cantilever of the return spring cannot be positioned stably. Once the phenomenon of slipping with the pawl occurs during the very frequent swing process, it will cause the complete failure of the speed change action of the transmission. As a result, the entire transmission transmission is stuck and the transmission components are damaged.

[0005] 2. Unreliable movement of centrifugal weight balance plate

In addition, various factors such as the accuracy of the parts (such as flatness, coaxiality, and axial pressing force) and the surface roughness of the parts will also cause inconsistency and large individual differences in the components that complete the shifting action

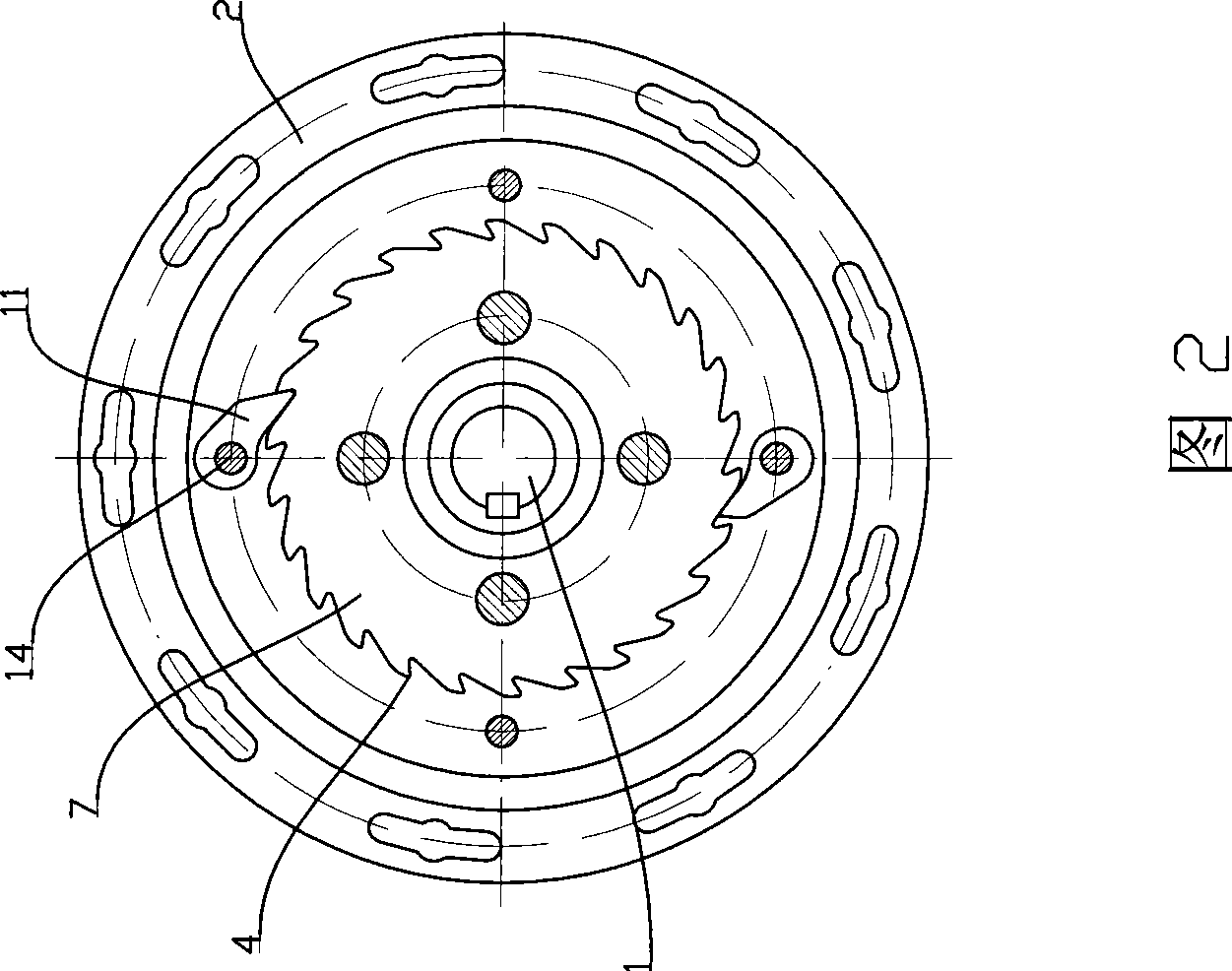

[0006] 3. Centrifugal mass balance accuracy is low

In this kind of transmission, the component that completes the swinging action in the centrifugal weight balance plate, that is, the swing lever plate and the fixed plate form a plane friction pair, and the swing lever plate and the fixed plate must form a certain radial direction between the rotating circumferential surfaces. Therefore, it will inevitably lead to the uncertainty of the center of rotation of the centrifugal block, which naturally forms a variable radius of rotation, so that the symmetrically arranged centrifugal blocks cannot achieve mass balance, resulting in the radial non-positioning of the swing rod disc, and finally making it impossible for the transmission to form a definite Shift action

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

[0035] The inner diameter of the rolling bearing may be 22mm, the outer diameter may be 28mm; the bead diameter may be 1.0mm.

Embodiment 3

[0037] The inner diameter of the rolling bearing may be 25mm, the outer diameter may be 31mm; the bead diameter may be 1.50mm.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

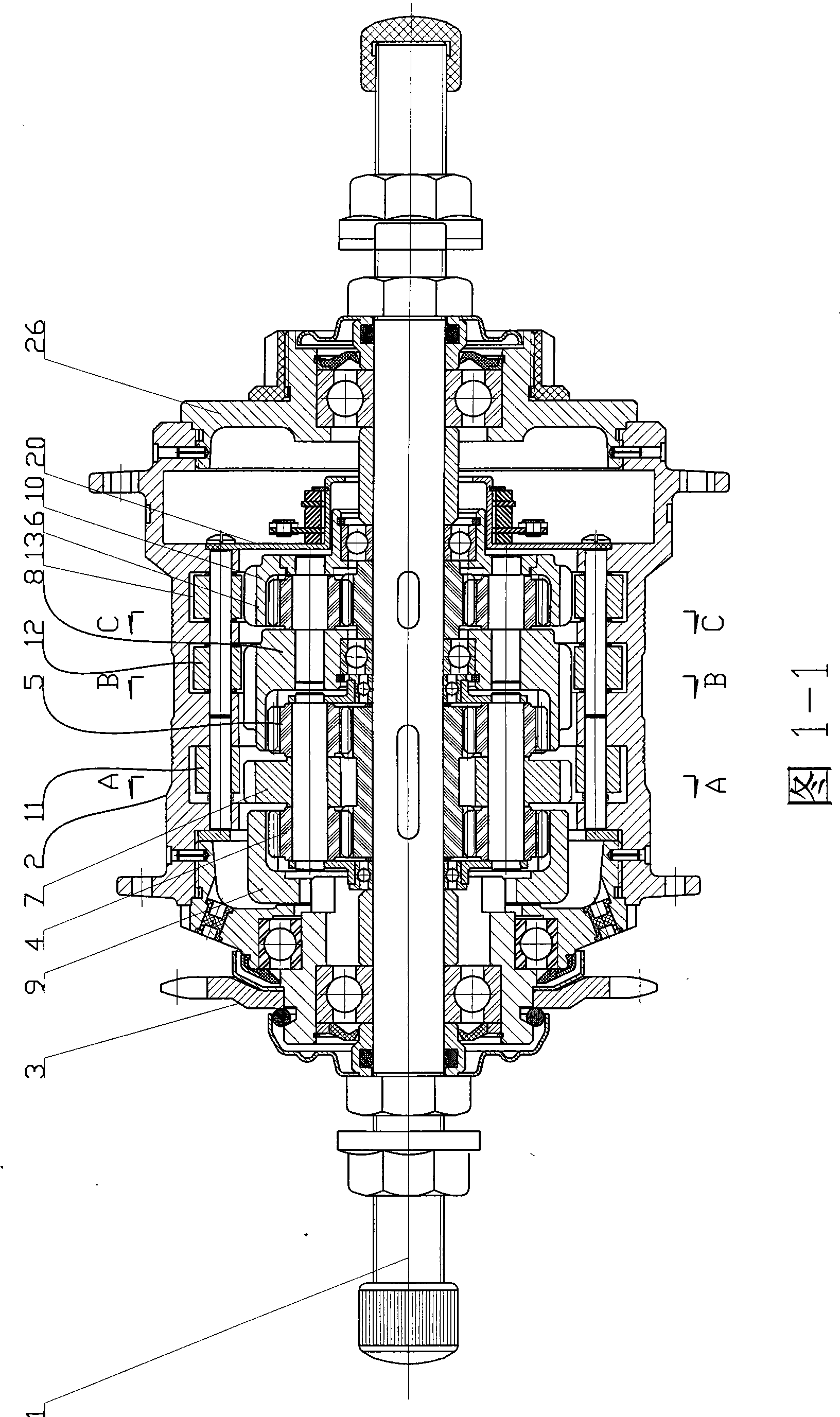

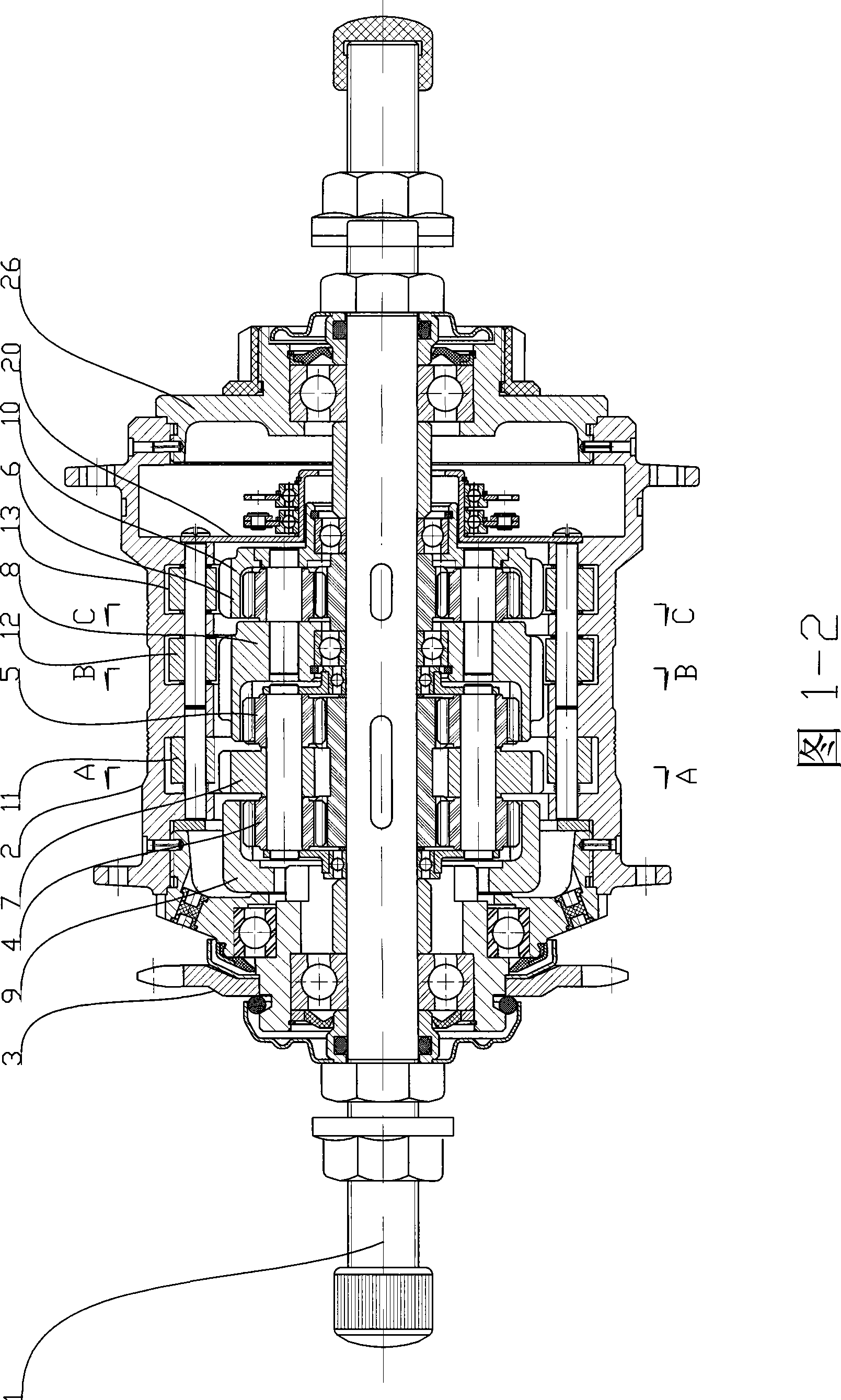

The invention discloses a full-automatic speed changer of bicycles. The speed changer comprises a variable speed drive device and a variable speed control device. The variable speed drive device is a three-stage planetary gear train structure which is coaxial with a main shaft, the variable speed control device comprises a part which comprises a constantly meshed output pawl and a constantly released control pawl which are evenly distributed on the outer circumference of the ring gear in the planetary gear train and three stages of the pawls are controlled by a reset spring; and an off-center block balance disc part which controls the meshing action of the pawls and the a ratchet. The off-center block balance disc comprises a fixed disc and a swing link disc which is arranged on the axial diameter of the fixed disc. The swing link disc is hinged with the control pawl through a gear connection rod and a pawl poke rod; a concave arc trough is arranged on the motion track formed by the sliding and swinging of the pawl poke arm along the reset spring; and a rolling bearing is arranged between the swing link disc and the axial diameter of the fixed disc. The full-automatic speed changer of bicycles has the advantages of high sensibility and high reliability of variable speed control.

Description

technical field [0001] The invention relates to a transmission structure, in particular to an improved structure of a bicycle automatic transmission. Background technique [0002] In the prior art, the Chinese Utility Model Patent (Patent No.: ZL 2004 2 0070090.3) discloses a solid-shaft automatic transmission for bicycles. The input mode, and the speed change control device must pass through a series of axial transmission devices, so it will generate a large axial transmission resistance, resulting in inflexible speed change; the speed change device has a planetary gear train, and the speed change is realized by changing the input position. In the three speed gears of low, medium and high, the gear cross wheel is the driving element of the transmission, and there is a relatively large bonding force between the gear cross wheel and the transmission element of the planetary gear train. Axial shifting and gear shifting, so when shifting, it is estimated that when the speed re...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B62M11/14B62M25/02

CPCB62M11/16B62M11/18

Inventor 程辉

Owner 程辉

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com