Modified emulsified bitumen for tie coat

A technology for emulsified asphalt and adhesive layer, which is used in road engineering modified emulsified asphalt and its processing and application fields, can solve problems such as insufficient viscosity and low solid content, and achieve the effects of improving waterproof performance and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Get 670g CNPC 70# common asphalt, 40g cationic styrene-butadiene polymer latex modifier (PC-1468), 3.5g fast-cracking emulsifier (INDULIN DF-42E) and 286.5g water for subsequent use.

[0018] Prepare the quick-cracking emulsifier (INDULIN DF-42E) and water according to the above proportions to make a soap solution, add the modifier cationic styrene-butadiene polymer latex (PC-1468) to the soap solution, and use 36% concentrated hydrochloric acid to dissolve the soap solution Adjust the pH value to 2.0, heat the soap solution to 58°C, and then circulate the colloid mill at a speed of 5000rpm at high speed to disperse the particles in the soap solution evenly, then slowly add PetroChina that has been heated to 132°C to the running colloid mill 70# asphalt, and then recirculate until the emulsion is evenly dispersed, and the obtained emulsion is the modified emulsified asphalt for the adhesive layer.

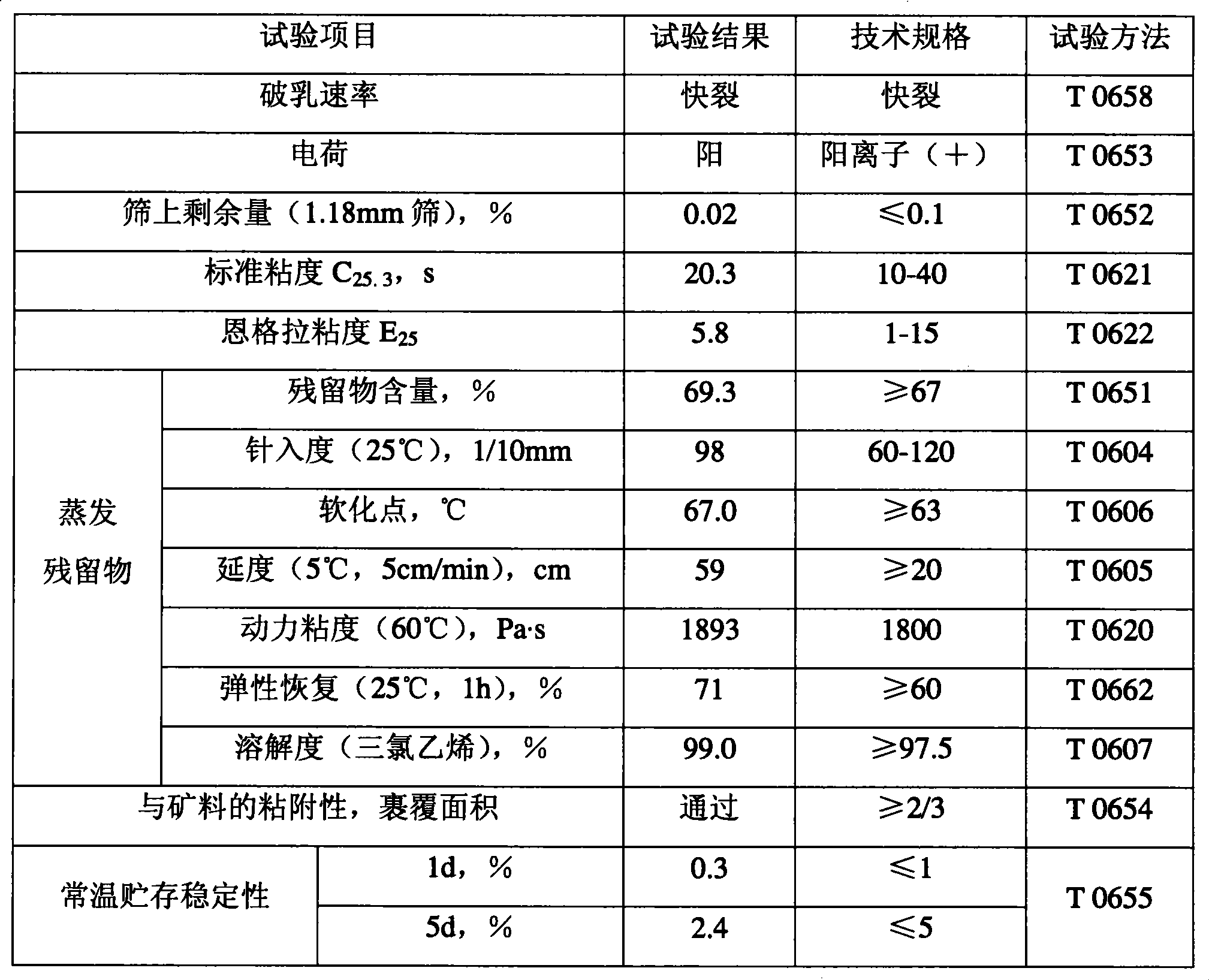

[0019] The technical indicators of the modified emulsified asphalt, esp...

Embodiment 2

[0023] Get 680g Korean SK70# common asphalt, 40g cationic styrene-butadiene polymer latex modifier (PC-1468), 4.5g fast-cracking emulsifier (INDULIN DF-42E) and 275.5g water for subsequent use.

[0024] Prepare quick-cracking emulsifier (INDULIN DF-42E) and water according to the above ratio to make soap liquid, add modifier cationic styrene-butadiene polymer latex latex (PC-1468) to soap liquid, and use 38% concentrated hydrochloric acid to dissolve the soap liquid Adjust the pH value of the liquid to 3.0, heat the soap to 55°C, and pass through a colloid mill with a speed of 4000rpm to circulate at a high speed to disperse the particles in the soap liquid evenly, then slowly add soap that has been heated to 130°C to the running colloid mill Korean SK70# asphalt, and then recirculate until the emulsion is evenly dispersed, and the obtained emulsion is the modified emulsified asphalt for the adhesive layer.

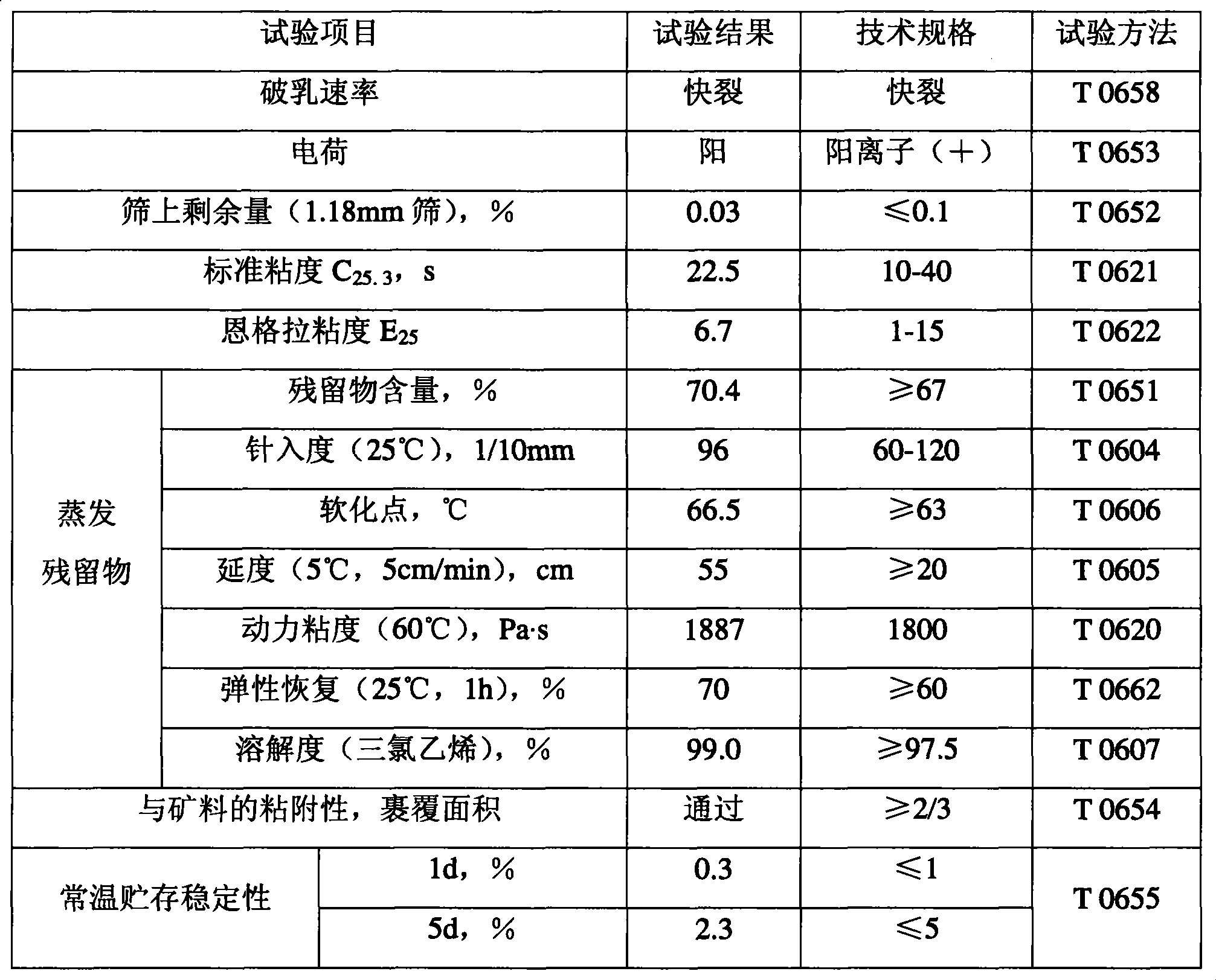

[0025] The technical indicators of the modified emulsified asphalt, ...

Embodiment 3

[0029] Get 650g of Singapore ESSO 70# common asphalt, 30g of cationic styrene-butadiene polymer latex modifier (PC-1468), 2.5g of fast-cracking emulsifier (INDULIN DF-42E) and 317.5g of water for subsequent use.

[0030] Prepare the quick-cracking emulsifier (INDULIN DF-42E) and water according to the above proportions to make a soap solution, add the modifier cationic styrene-butadiene polymer latex (PC-1468) to the soap solution, and use 36% concentrated hydrochloric acid to dissolve the soap solution Adjust the pH value to 2.0, heat the soap to 60°C, and then circulate the colloid mill at a speed of 6000rpm at high speed to disperse the particles in the soap liquid evenly, then slowly add Singaporean soap heated to 145°C to the running colloid mill. ESSO70# asphalt, and then recirculate until the emulsion is uniformly dispersed, and the obtained emulsion is the modified emulsified asphalt for the adhesive layer.

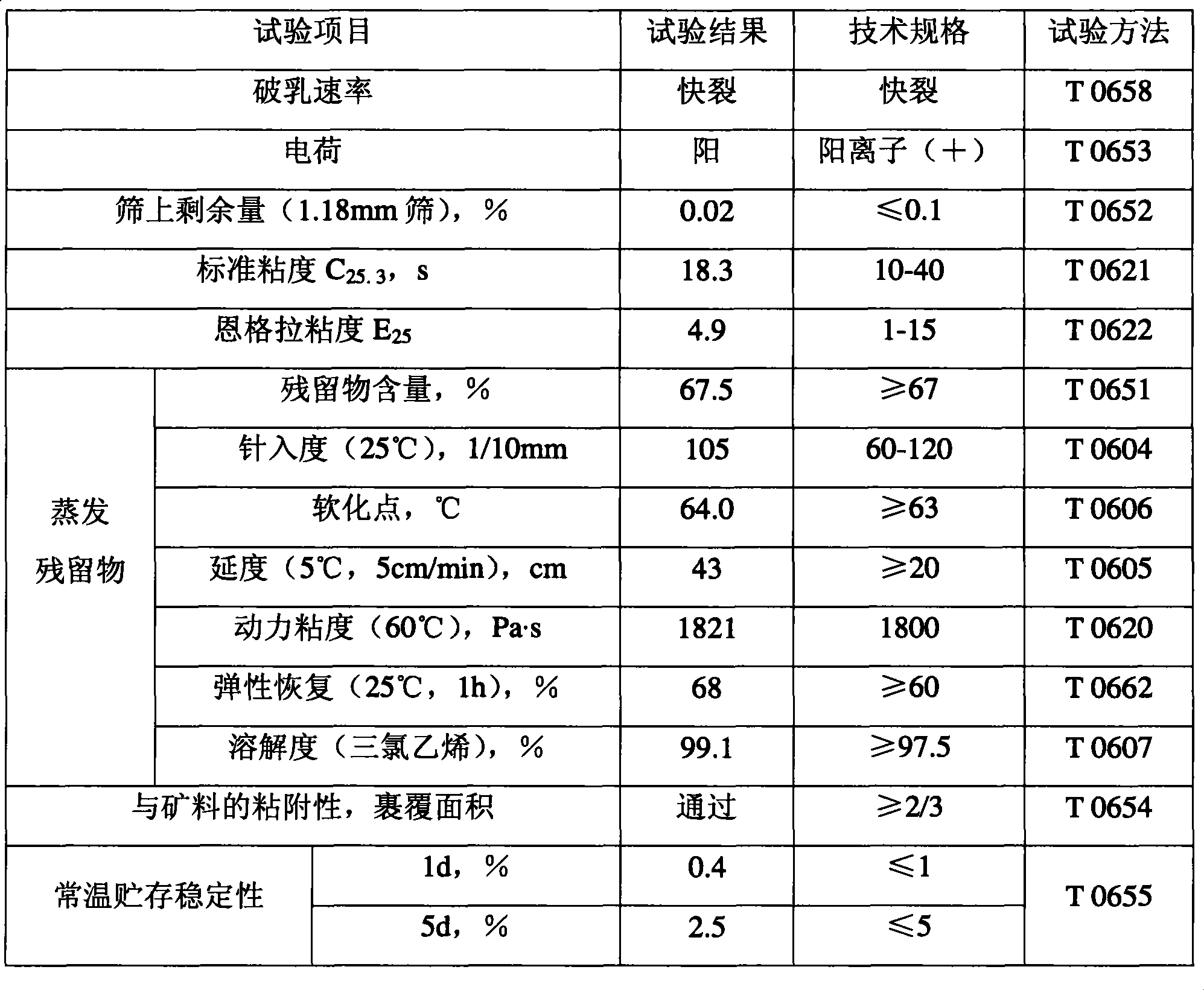

[0031] The technical indicators of the modified emulsified a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com