Silicon chip product defect analysis method and device

A defect analysis and silicon wafer technology, applied in measurement devices, analysis materials, material analysis by optical means, etc., can solve the problems of high level requirements, untimely response, low production efficiency, etc., to ensure repeatability and comparability performance, saving storage space, and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

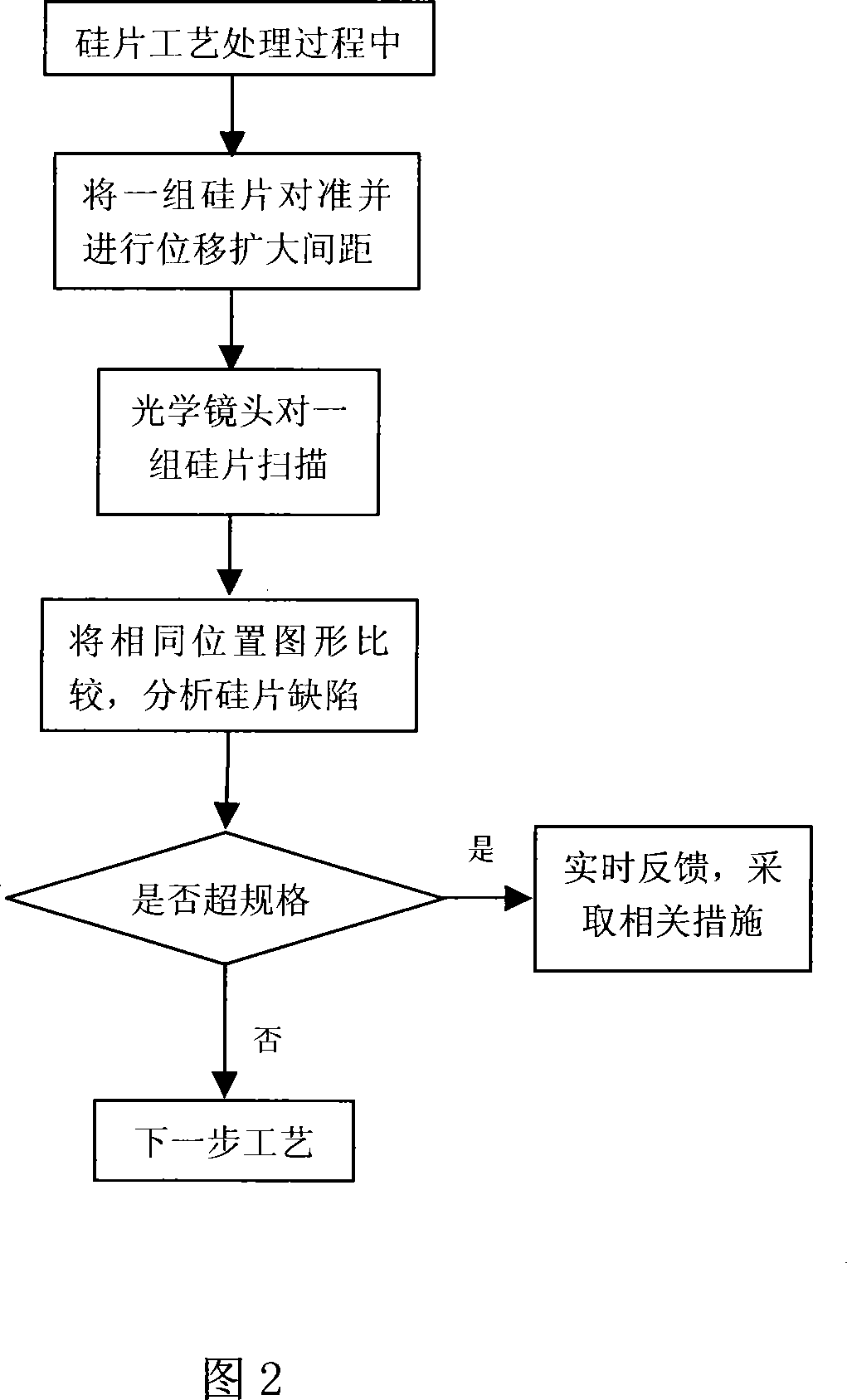

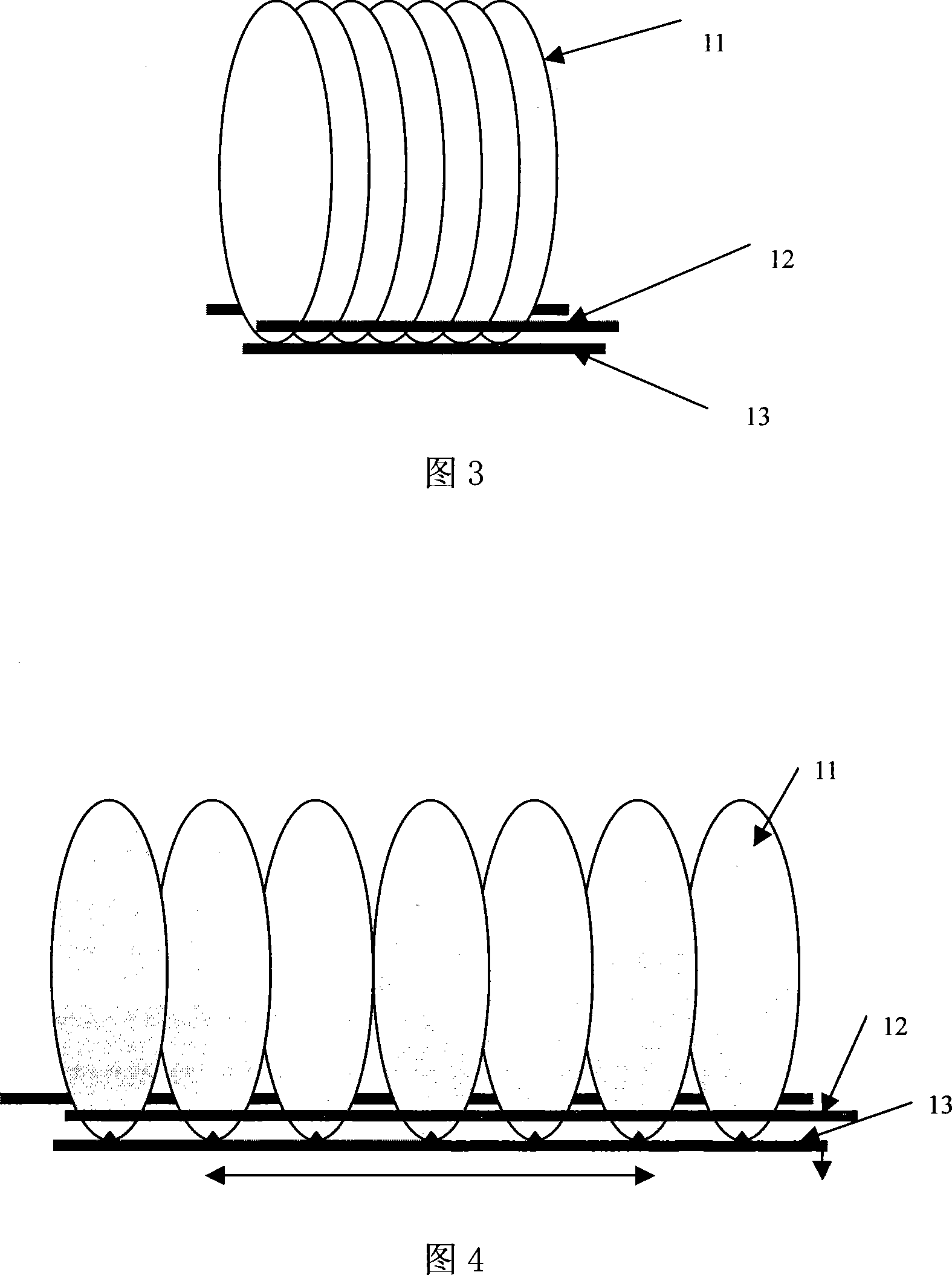

[0021] One embodiment of the defect analysis method for silicon wafer products of the present invention is as follows: figure 2 As shown, in the manufacturing process of silicon wafer products, the graphics at the same position of a batch of silicon wafer products should be the same, and a group of identical silicon wafer products (such as 3 to 25 pieces) are placed on the silicon wafer displacement device, Correspond to the same position of the same group of silicon wafer products, and adjust the distance between each silicon wafer product, so that a set of scanning lenses is placed between the group of silicon wafer products, and at the same time, the same position of the same group of silicon wafer products Scan the graphics, and then use special defect analysis equipment to compare the graphics scanned at the same position of the same group of silicon wafer products to find deviations and abnormalities in the graphics, that is, to find a certain silicon wafer in the group ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com