Electro-optical device and electronic apparatus

一种电光学装置、电极的技术,应用在电光源、辨认装置、照明装置等方向,能够解决发光亮度不均匀、有机EL薄膜困难、膜厚高度不均匀等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

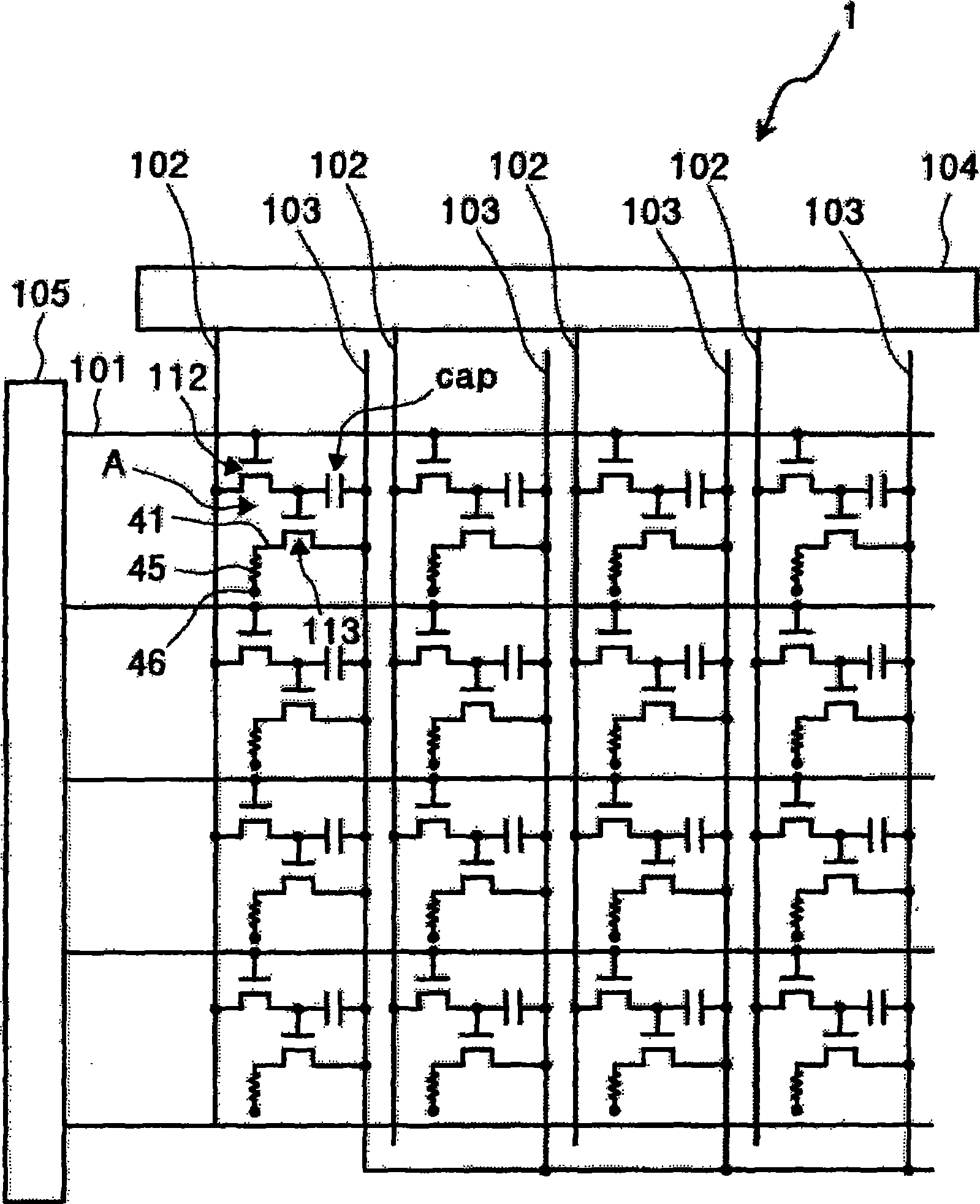

[0054] figure 1 A schematic plan view showing the wiring structure of the electro-optical device according to the present invention. as it should figure 1 As shown in , the electro-optical device 1 is respectively arranged with: a plurality of scanning lines 101; a plurality of signal lines 102 spaced apart from the scanning lines 101 and extending in a direction substantially perpendicular to each other; A plurality of power lines 103. Next, pixel regions A are provided in a matrix near each intersection of the scanning lines 101 and the signal lines 102 .

[0055] A data drive circuit 104 including a shift register, a level shifter, a video line, and an analog switch is connected to the signal line 102 . Furthermore, a scanning-side driver circuit 105 including a shift register and a level shifter is connected to the scanning line 101 .

[0056] The pixel area A is respectively provided with: a TFT 112 for switching, which supplies a scanning signal to the gate electro...

no. 2 Embodiment approach

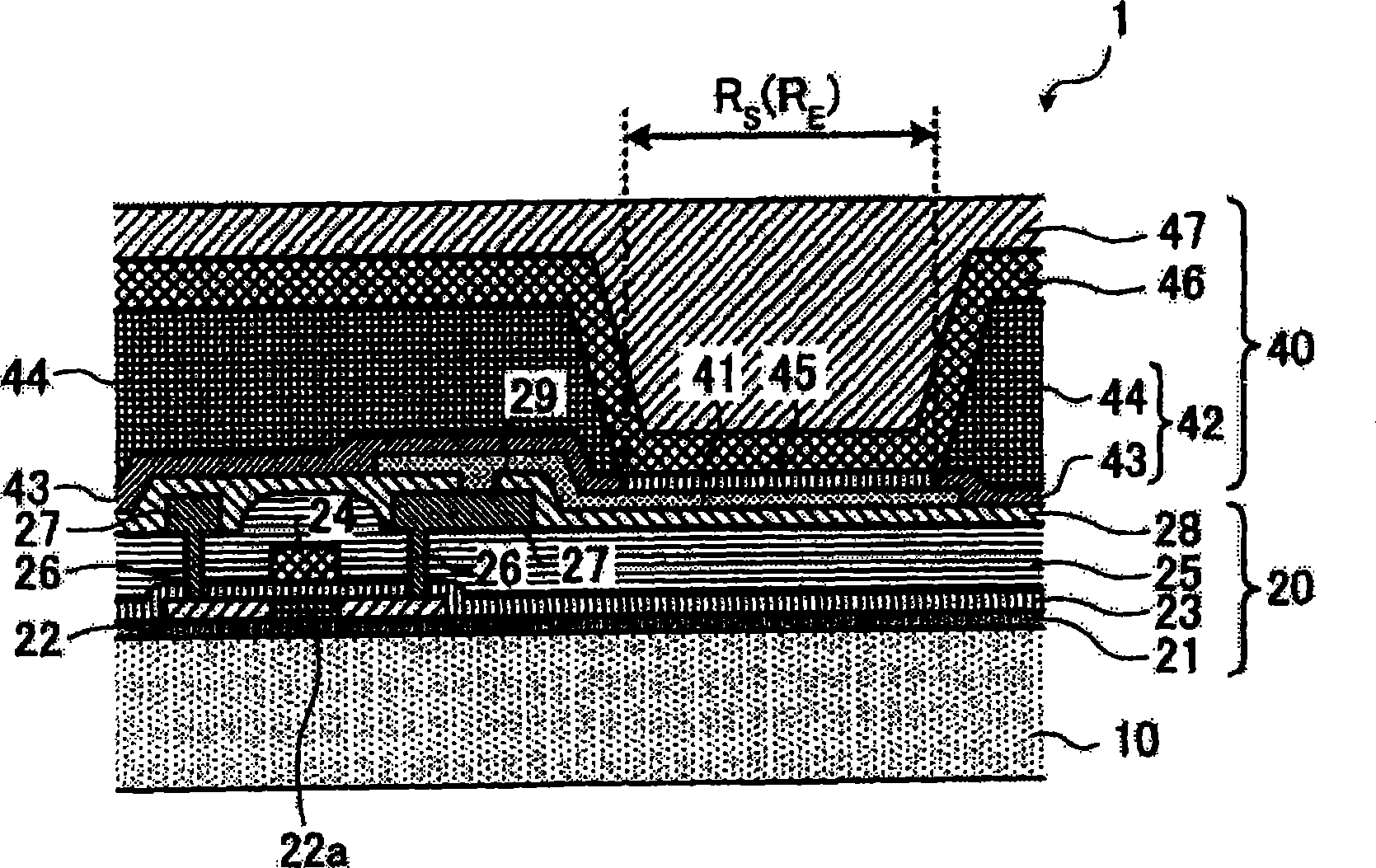

[0082] In the second embodiment, the configuration of the electro-optical device in the case where the functional layer 45 has at least a light-emitting layer and an auxiliary layer formed under the light-emitting layer will be described. Figure 9 A cross-sectional view showing a main part of a second embodiment of the electro-optical device according to the present invention. This electro-optical device is characterized in that the first partition wall 43a has a two-layer structure of the third partition wall 43aa and the fourth partition wall 43ab, and the partition wall 42a has a three-layer structure. The structure of the partition wall 42a includes: a third partition wall 43aa formed on the drive element portion 20, capable of surrounding the droplet ejection region R S and have lyophilicity; the fourth partition wall 43ab is formed on the third partition wall 43aa and has lyophilicity; the second partition wall 44a is formed on the fourth partition wall 43ab and has liq...

no. 3 Embodiment approach

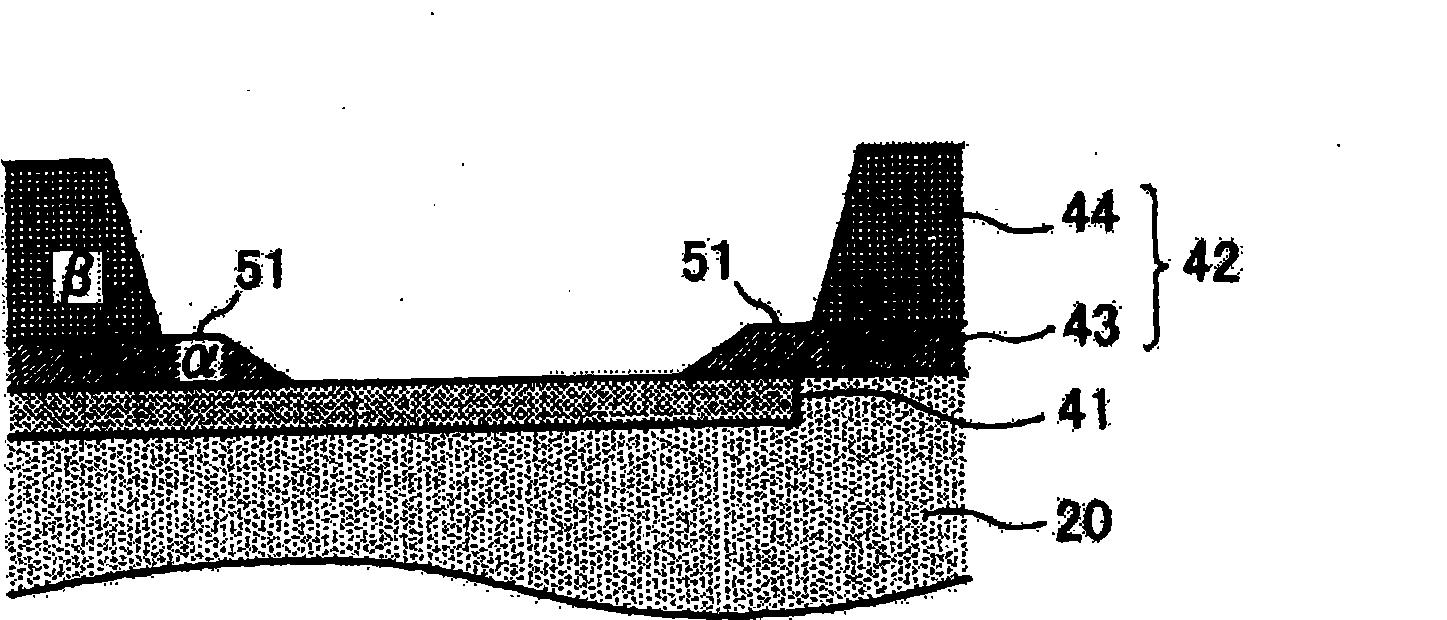

[0094] In this third embodiment, in the electro-optical device having a rectangular droplet ejection region, the region surrounding the first partition wall has a uniform film thickness, and the height of the surface of the functional layer in the droplet ejection region is The configuration of a uniform electro-optical device will be described.

[0095] Figure 10 A plan view showing the configuration of a third embodiment of the electro-optical device according to the present invention, Figure 11 express Figure 10 A—A sectional view of , and then Figure 12 express Figure 10 The B-B cross-sectional view. In these figures, only the droplet ejection region and the peripheral portion of the partition wall are shown. According to the electro-optical device of the third embodiment, the cross-sectional shape is the same as that of the second embodiment. Figure 9 Similarly, its partition wall 42a has a three-layer structure of the third and fourth partition walls 43aa, 43ab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| cure temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com