Steel sheet for submerged arc welding

A technology of submerged arc welding and steel plate, applied in welding medium, welding equipment, welding/cutting medium/material, etc., can solve the problems of reduced toughness of HAZ and base metal, no measurement of low temperature toughness of weld metal, reduced low temperature toughness of weld metal, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

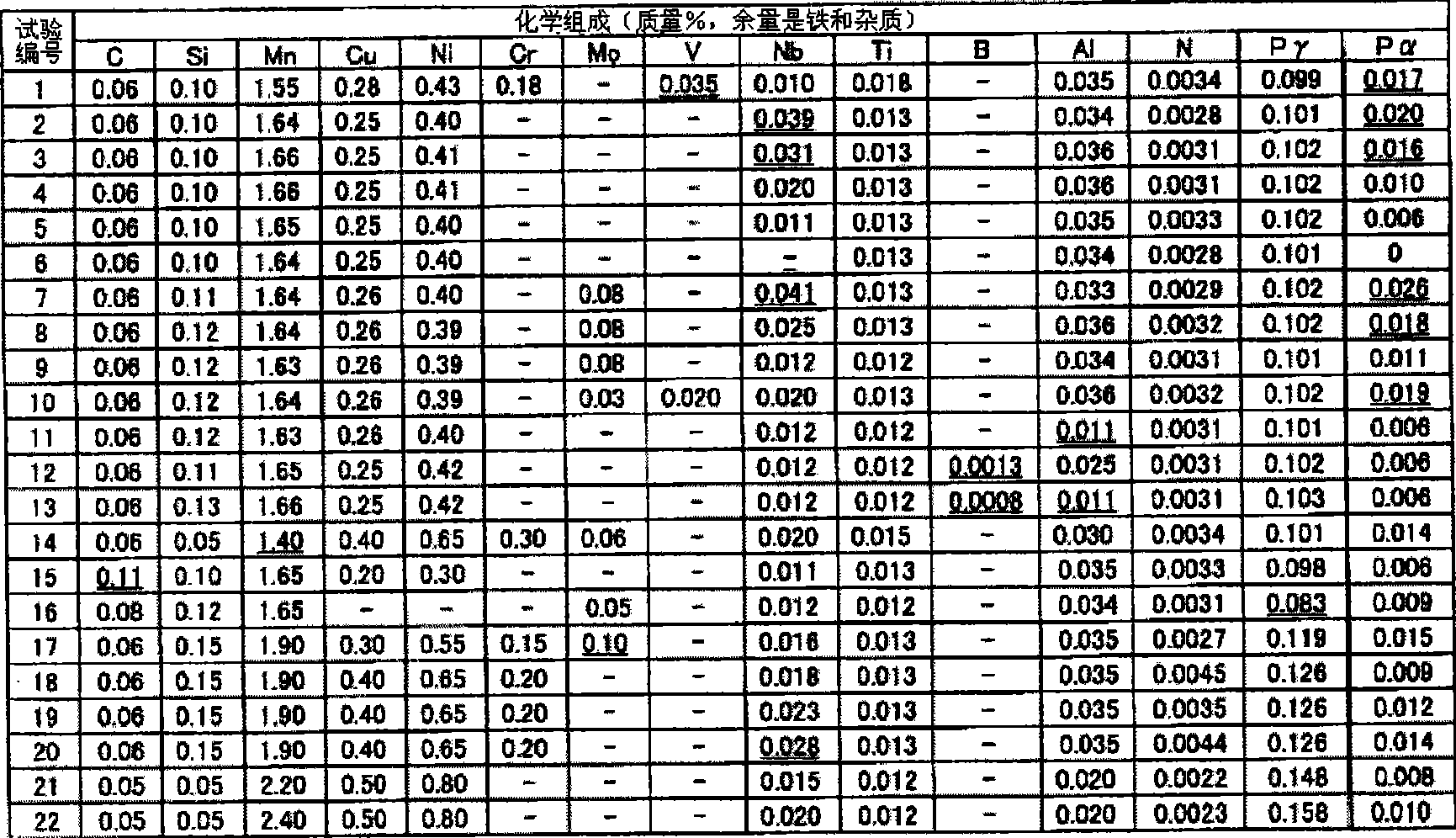

[0086] Steel sheets having the chemical compositions shown in Table 1 were produced, submerged arc welding was performed, and the low temperature toughness of welded parts was investigated.

[0087] Table 1

[0088]

[0089] __ represents outside the scope of the present invention.

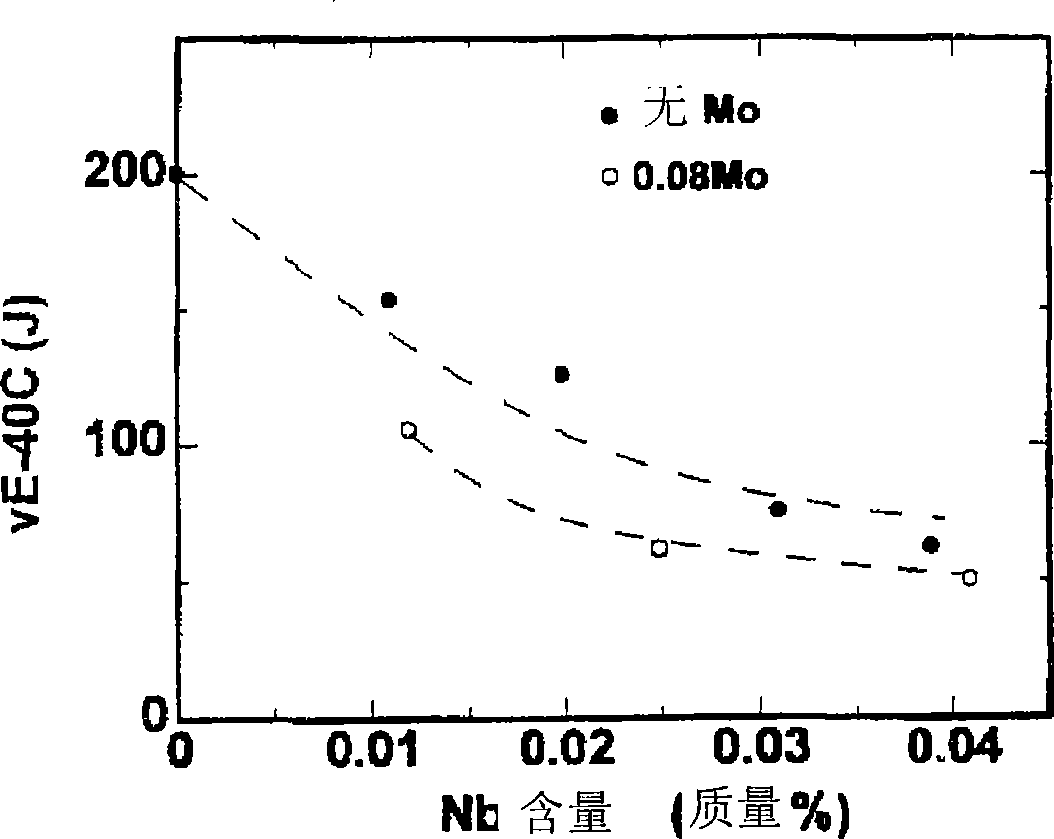

[0090] Pα=(Mo / 15+V / 3+Nb / 2)

[0091] Pγ=(Mn / 20+Cu / 20+Ni / 60)

[0092] Steel materials having the chemical compositions shown in Table 1 were prepared. In addition, the P content, S content, and O content of each test number were all within the range of the present invention. The prepared steel is melted in a small vacuum melting furnace with a capacity of 150kg to make ingots. After the manufactured ingot was heated at 1150°C for 2 hours, a steel sheet with a height of 150mm, a width of 130mm and a length of 130mm was made by forging. The temperature of the material during forging is 900-1150°C. After heating the manufactured steel sheet at 1100°C, it is rolled into a steel plate. By rolling,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com