Edulcoration purification process for rhizoma paris saponin extract solution

The technology of Chonglou saponin and extract is applied in the directions of pharmaceutical formulations, medical preparations containing active ingredients, plant raw materials, etc., can solve problems such as low efficiency, and achieve the effects of easy operation, simple process and high content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

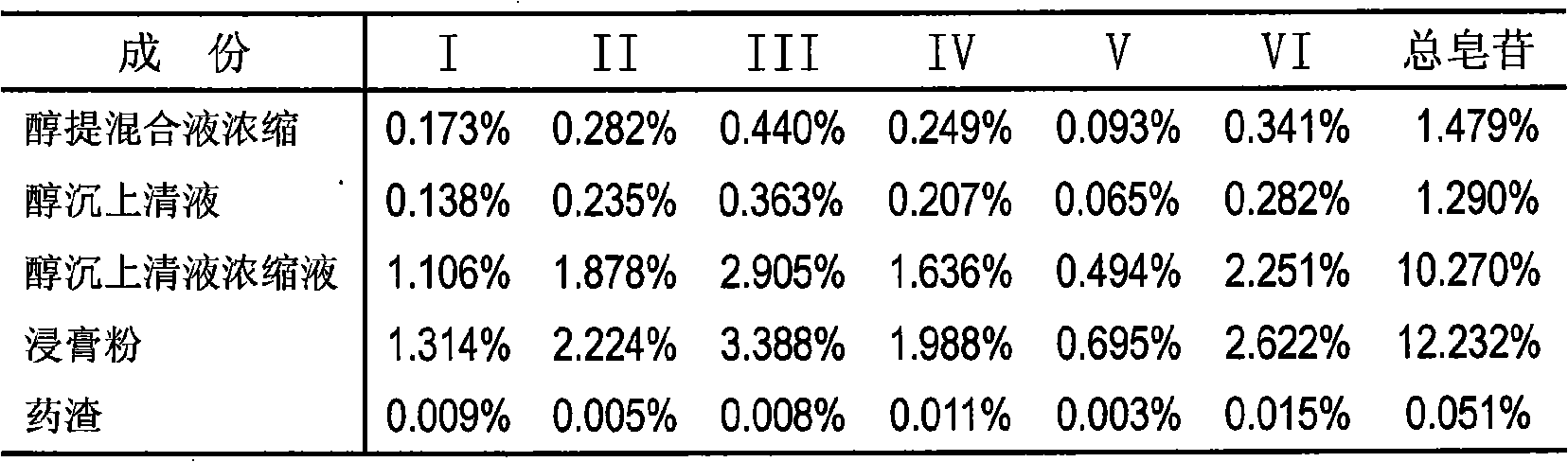

[0049]Example 1: Take 100 kilograms of dried rhizomes of Yunnan Zhonglou, crush them into coarse powder, extract them with 1,000, 500, and 500 kilograms of 70% ethanol for 5, 4, and 3 hours respectively, combine the extracts, and filter to remove impurities such as medicine residue and mud , The crude extract of saponins from Chonglou saponins is obtained, and the organic solvent is recovered after concentration under reduced pressure. 1g of amylase or pectinase is added to each liter of concentrated solution to make a suspension, and the ethanol content in the suspension is controlled to be less than 5 %, the final solution density is 1.01 (measured with a densimeter at 25°C) and the volume is 0.40 cubic meters. The suspension was filtered with an inorganic ceramic membrane, the ceramic membrane material was zirconium dioxide (ZrO2) membrane, the membrane pore size was 0.05μm, the retentate was collected, concentrated, and dried to obtain 5.4 kg of the extract of saponins of sapo...

Embodiment 2

[0050] Example 2: Take 80 kilograms of dried rhizomes of Yunnan Zhonglou, crush them into coarse powder, extract them with 800, 400, and 400 kilograms of 60% ethanol for 5, 4, and 3 hours respectively, combine the extracts, and filter to remove impurities such as slag and mud , The crude extract of saponins from Chonglou saponins is obtained, and the organic solvent is recovered after concentration under reduced pressure. 2g of amylase or pectinase is added to each liter of concentrated solution to make a suspension, and the ethanol content in the suspension is controlled to be less than 7 %, the final solution density is 1.01 (measured with a densimeter at 25°C) and the volume is 0.35 cubic meters. The suspension was filtered with an inorganic ceramic membrane. The material of the ceramic membrane was a zirconium dioxide (ZrO2) membrane with a pore size of 0.05μm. The retentate was collected, concentrated, and dried to obtain 4.0 kg of the extract of the saponins of the saponins ...

Embodiment 3

[0051] Example 3: Take 50 kilograms of dried rhizomes of Aesculus vulgaris, crush them into coarse powder, extract them with 500, 400, and 400 kilograms of 80% ethanol for 8, 5, and 3 hours respectively, combine the extracts, and filter to remove medicine residues, silt, etc. Impurities, the crude extract of saponins from Chonglou saponins is obtained, and the organic solvent is recovered after concentration under reduced pressure. 3g of amylase or pectinase is added to each liter of concentrated solution to make a suspension, and the ethanol content in the suspension is controlled to be lower than 10%, so that the final solution density is 1.02 (measured with a densimeter at 25°C) and the volume is 0.15 cubic meters. The suspension was filtered with an inorganic ceramic membrane, the ceramic membrane material was zirconium dioxide (ZrO2) membrane, the membrane pore size was 0.10μm, the retentate was collected, concentrated, and dried to obtain 2.3 kg of Chonglou saponin extract, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Membrane pore size | aaaaa | aaaaa |

| Membrane pore size | aaaaa | aaaaa |

| Membrane pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com