Albumin based polyacrylic acid nano-carrier and preparation method thereof

A polyacrylic acid and nano-carrier technology, which is applied in the direction of inactive components of polymer compounds, can solve the problems of complex process, high equipment requirements, poor biocompatibility and biodegradability, etc., and achieves simple preparation process and strong hydrophilicity. , improve the effect of drug efficacy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

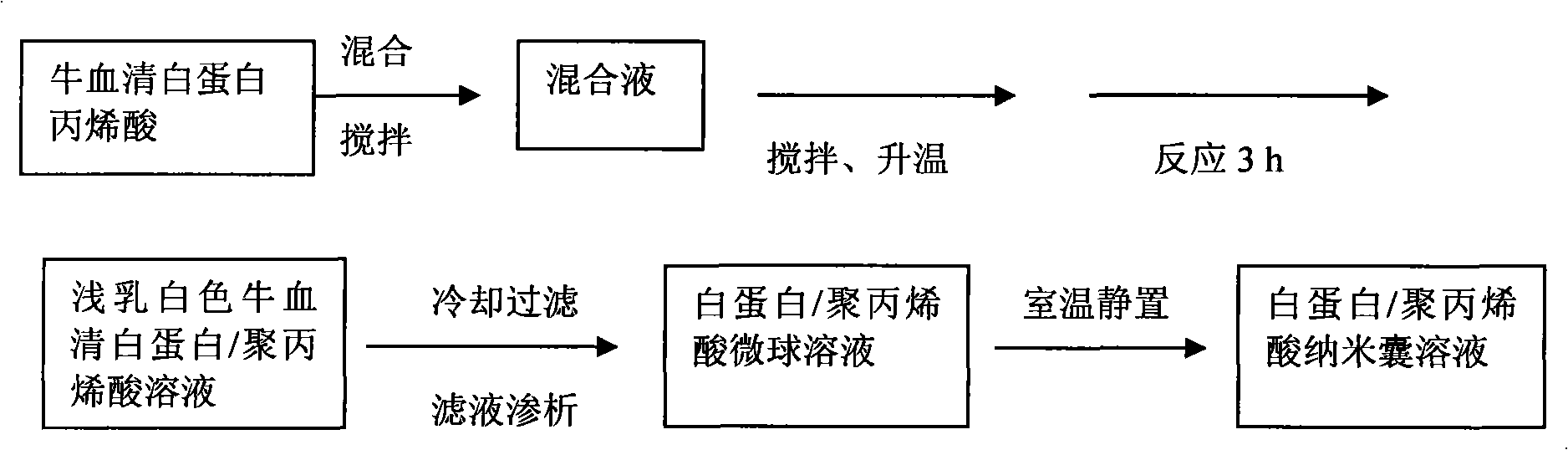

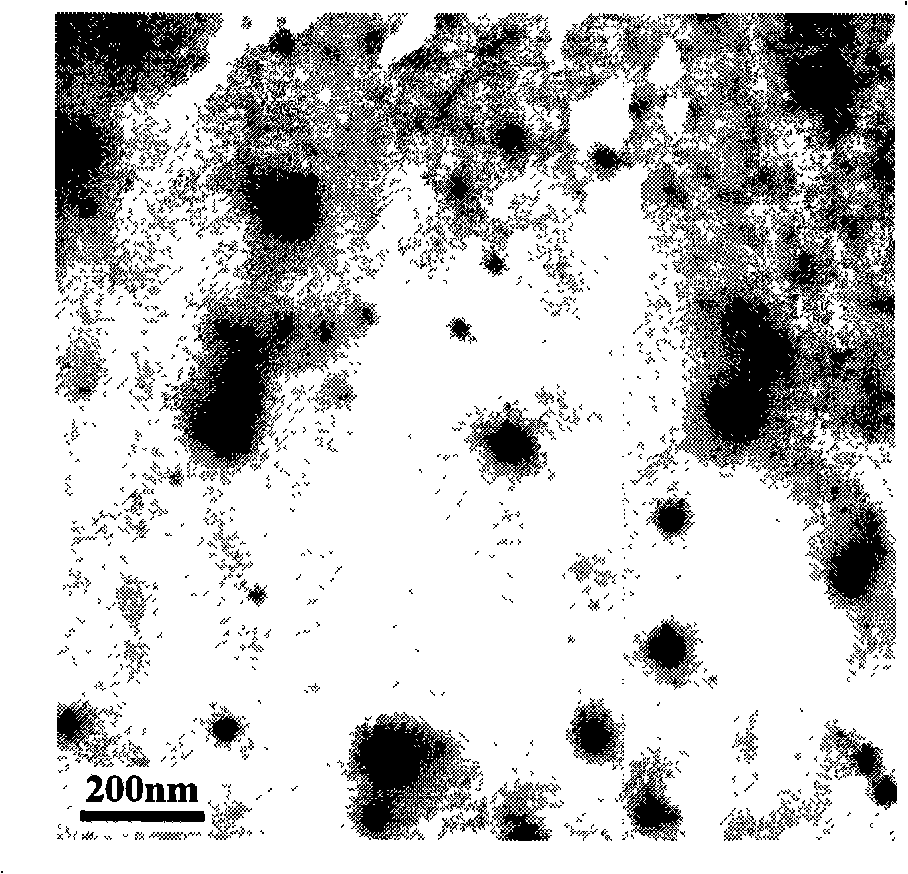

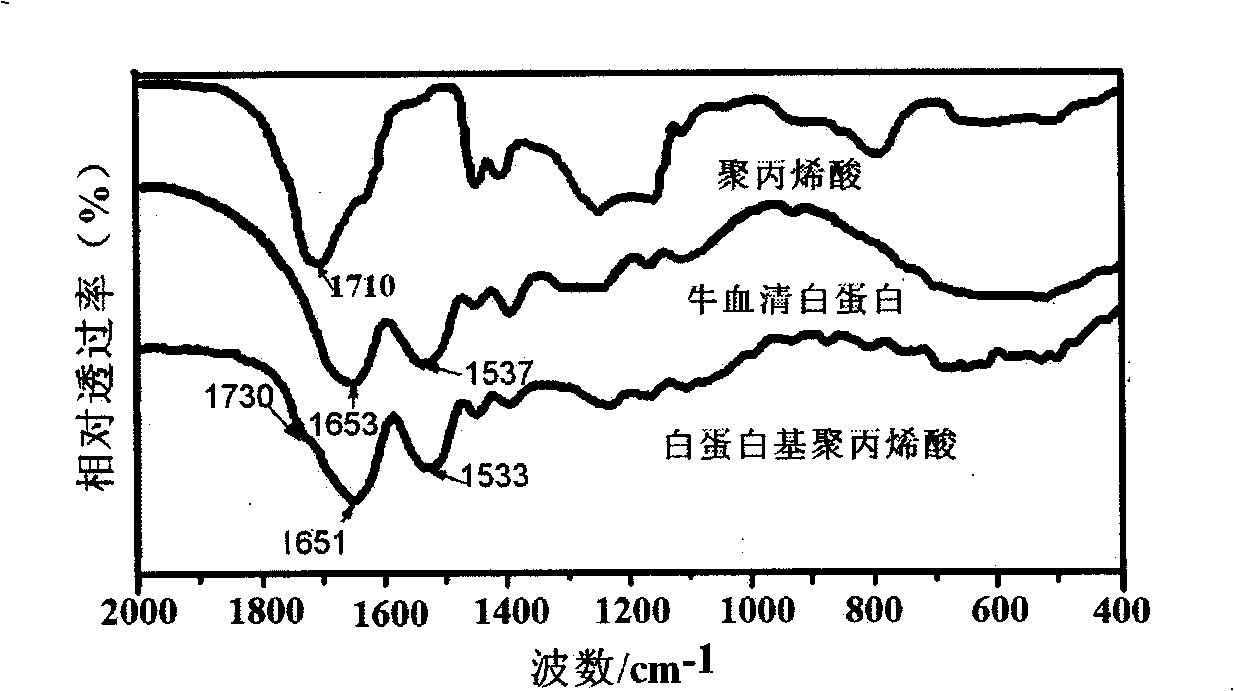

[0039] Embodiment 1: (a) take a certain amount of bovine serum albumin solid, and make it into an albumin solution with a concentration of 0.005 mg / mL; (b) purify acrylic acid by vacuum distillation; (c) take the above-mentioned prepared albumin solution Put 10 mL of protein solution in a 50 mL three-necked flask, add 0.2 mg of purified acrylic acid, stir mechanically for 5 min to fully disperse acrylic acid in the albumin solution; (d) stir the mixed solution under nitrogen protection for 10 min, then heat up to 80°C, add 0.006 mg K 2 S 2 o 8 As an initiator, 0.004mg TEMED was used as an accelerator, and reacted for 4 hours under mechanical stirring; (f) after the reaction, the solution was cooled to room temperature, filtered, and the filtrate was dialyzed at room temperature for 45 hours to remove the initiator, unreacted acrylic acid and free acrylic acid oligomers to obtain albumin / polyacrylic acid nano-microspheres; (e) the dialyzed solution was allowed to stand at roo...

Embodiment 2

[0041] Example 2: (a) take a certain amount of bovine serum albumin solid, and make it into an albumin solution with a concentration of 0.005 mg / mL; (b) purify acrylic acid by vacuum distillation; (c) take the above-mentioned prepared albumin solution Put 10 mL of protein solution in a 50 mL three-necked flask, add 1.0 mg of purified acrylic acid, and stir mechanically for 10 min to fully disperse acrylic acid in the albumin solution; (d) Stir the mixed solution for 10 min under nitrogen protection, then heat up to 80°C, add 0.03 mg K 2 S 2 o 8 , 0.02g TEMED as an initiator, reacted for 4 hours under mechanical stirring; (f) after the reaction, the solution was cooled to room temperature, filtered, and the filtrate was dialyzed at room temperature for 45 hours to remove the initiator and unreacted acrylic acid and free acrylic acid oligomerization body to obtain albumin / polyacrylic acid nanospheres; (e) the dialyzed solution was allowed to stand at room temperature for 15 da...

Embodiment 3

[0043] Example 3: (a) take a certain amount of bovine serum albumin solid, and make it into an albumin solution with a concentration of 0.005 mg / mL; (b) purify acrylic acid by vacuum distillation; (c) take the above-mentioned prepared albumin solution Put 10 mL of protein solution in a 50 mL three-necked flask, add 1.0 mg of purified acrylic acid, and stir mechanically for 10 min to fully disperse acrylic acid in the albumin solution; (d) Stir the mixed solution for 10 min under nitrogen protection, then heat up to 65°C, add 0.03 mg K 2 S 2 o 8 , 0.02mg TEMED was used as an initiator, and reacted for 4 hours under mechanical stirring; (f) after the reaction, the solution was cooled to room temperature, filtered, and the filtrate was dialyzed at room temperature for 45 hours to remove the initiator, unreacted acrylic acid and free acrylic acid oligomerization body to obtain albumin / polyacrylic acid nanospheres; (e) the dialyzed solution was allowed to stand at room temperatur...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap