Treatment method and apparatus for mifepristone wastewater

A technology for mifepristone and wastewater treatment, which is applied in natural water body treatment, neutralized water/sewage treatment, water/sewage multi-stage treatment, etc. Ideal and other issues, to achieve the effect of saving oxygen consumption, reducing ammonia nitrogen load, and saving power costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

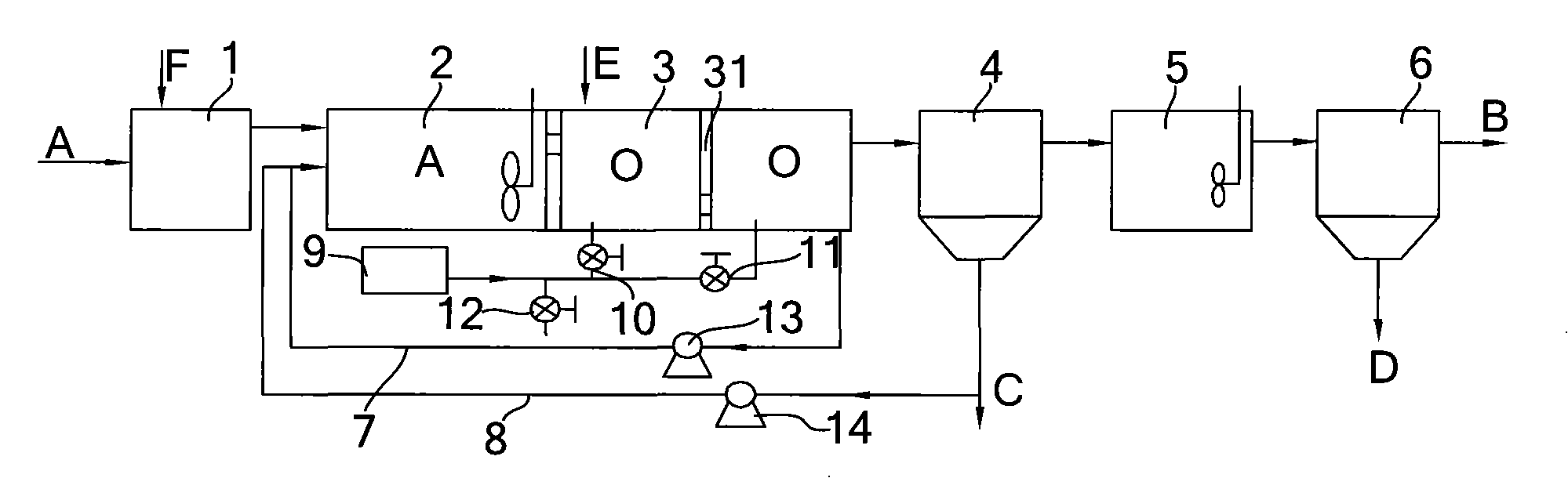

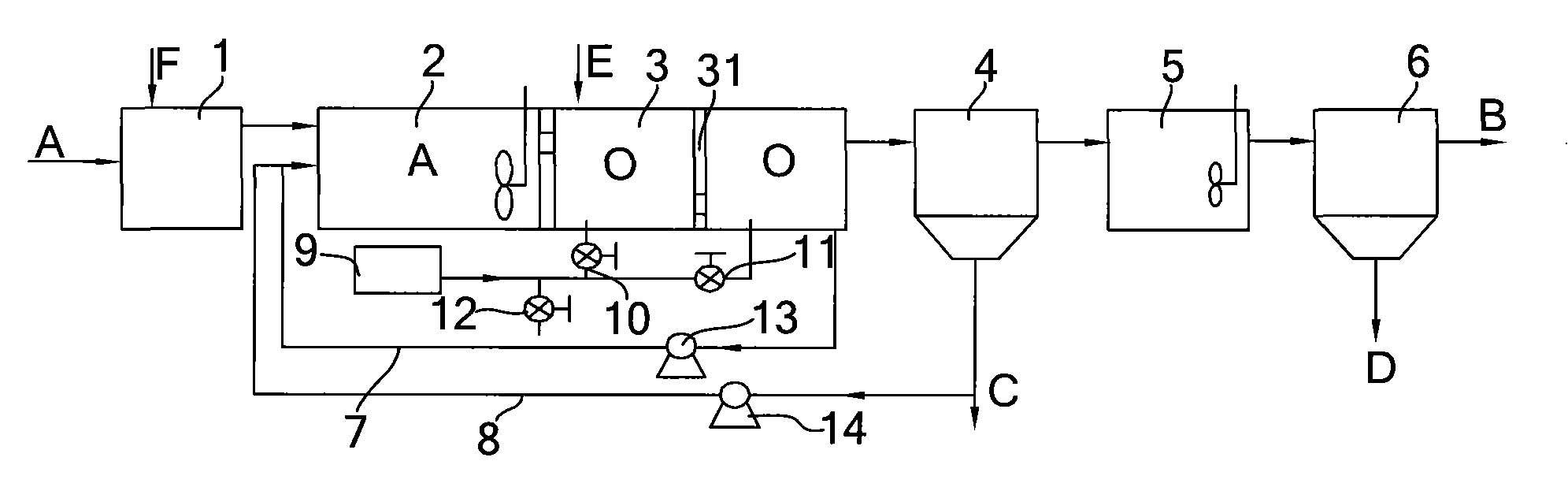

[0025] The treatment equipment adopted in a kind of mifepristone production wastewater treatment method provided by the present embodiment is as follows: figure 1 As shown, the equipment includes: regulating tank unit 1, facultative oxygen reactor 2, aerobic reactor 3, secondary settling tank 4, coagulation reactor 5 and coagulation sedimentation tank 6; wherein, regulating pond unit 1, facultative oxygen The reactor 2, the aerobic reactor 3, the secondary sedimentation tank 4, the coagulation reaction tank 5 and the coagulation sedimentation tank 6 are connected in sequence, and the aerobic reactor 2 and the aerobic reactor 3 are combined into an integrated structure; the adjustment tank unit The water inlet pipe of 1 is connected to the mifepristone wastewater inlet pipe; the aerobic reactor 3 is connected to the facultative oxygen reactor 2 through the mixed liquid return pipe 7 times; the sludge outlet C of the secondary sedimentation tank 4 is passed through the sludge ret...

Embodiment 2

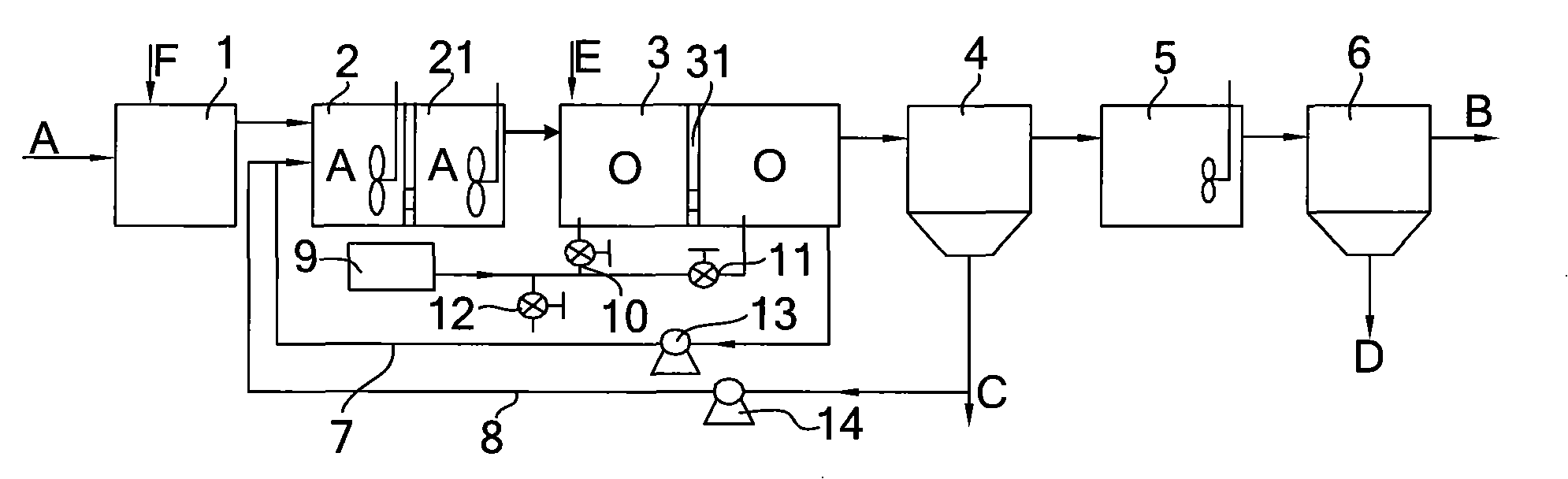

[0036] In the present embodiment, mifepristone production wastewater treatment equipment such as figure 2 As shown, each structure of this treatment equipment is the same as that of the treatment equipment in Embodiment 1, and the difference with the treatment equipment of Implementation 1 is that the concurrent oxygen reactor of the equipment is divided into two sections by a partition wall with a through hole. This structure of facultative oxygen reactor is beneficial to the separation and enrichment of facultative and anaerobic microorganisms, and improves the reaction rate of denitrification and anammox; in addition, the facultative oxygen reactor and aerobic reactor of this equipment are built separately The split structure, the facultative aerobic reactor and aerobic reactor of this split structure is conducive to adapting to the needs of the sewage treatment project site, with strong adaptability and convenient construction.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface load factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com