Flexible ultraviolet light curing offset printing ink

A technology of offset printing ink and ultraviolet light, which is applied in the field of ink, can solve the problems of high flexibility and fast curing speed, ink balance, pigment wetting, viscosity, and flexibility that cannot meet high-speed printing, etc., to achieve high flexibility and fast curing speed , the effect of increasing flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

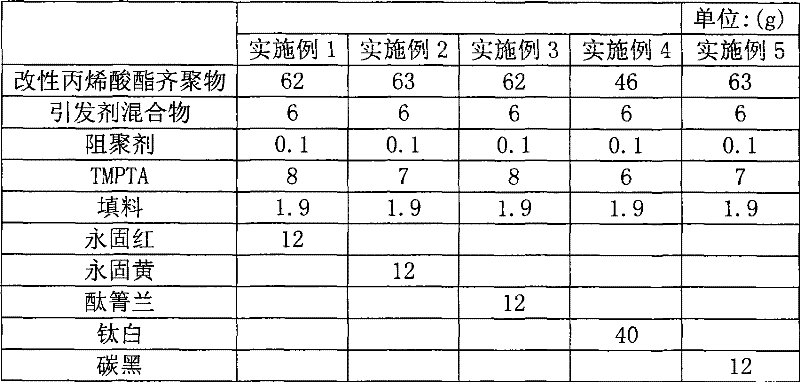

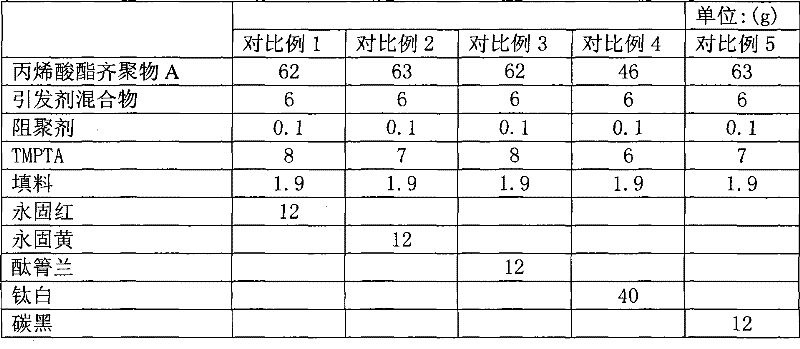

Embodiment 1~5

[0035] First prepare the modified acrylate oligomer: SAA resin is a commercially available finished product, which has three types, namely SAA-100, SAA-101, and SAA-103; when preparing the modified acrylate oligomer, mix 600g SAA- 100,314g polyhexadiene monoacrylate, 11g butadiene, 1000g toluene, 40g p-hydroxyanisole, 0.5g cuprous oxide (Cu 2 (2), 9.7g hypophosphorous acid add in the reactor. While stirring, the material was slowly raised to 110° C., and reacted at 110° C. for 10 hours until the reaction speed slowed down. The reaction kettle is kept warm and stirred continuously, and the acid value of the above-mentioned reaction materials is detected every 5 to 25 minutes. When the acid value is less than or equal to 5mgKOH / g, the temperature of the reaction kettle is lowered to 90°C, and the toluene is distilled under reduced pressure until no toluene flows out. The temperature of the kettle continues to decrease to obtain a modified polyester acrylate with a viscosity of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com