Dust collecting and processing system in textile machine

A treatment system and mechanical technology, applied in the field of cotton collection treatment system, can solve the problems of increasing the size of the blower, increasing the energy consumption, and increasing the size of the machine, so as to reduce the cross-sectional area, reduce the pressure loss, reduce the The effect of machine size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

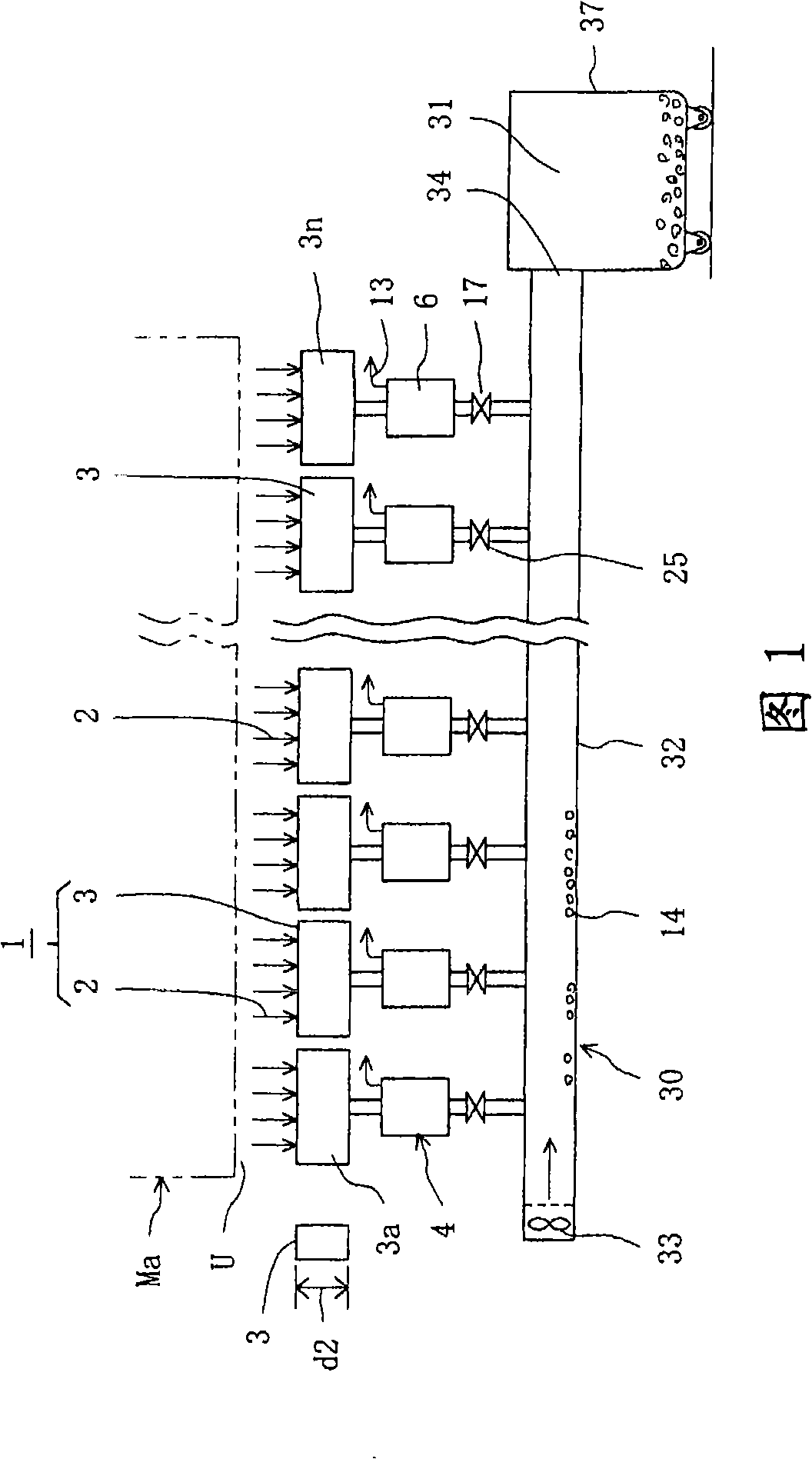

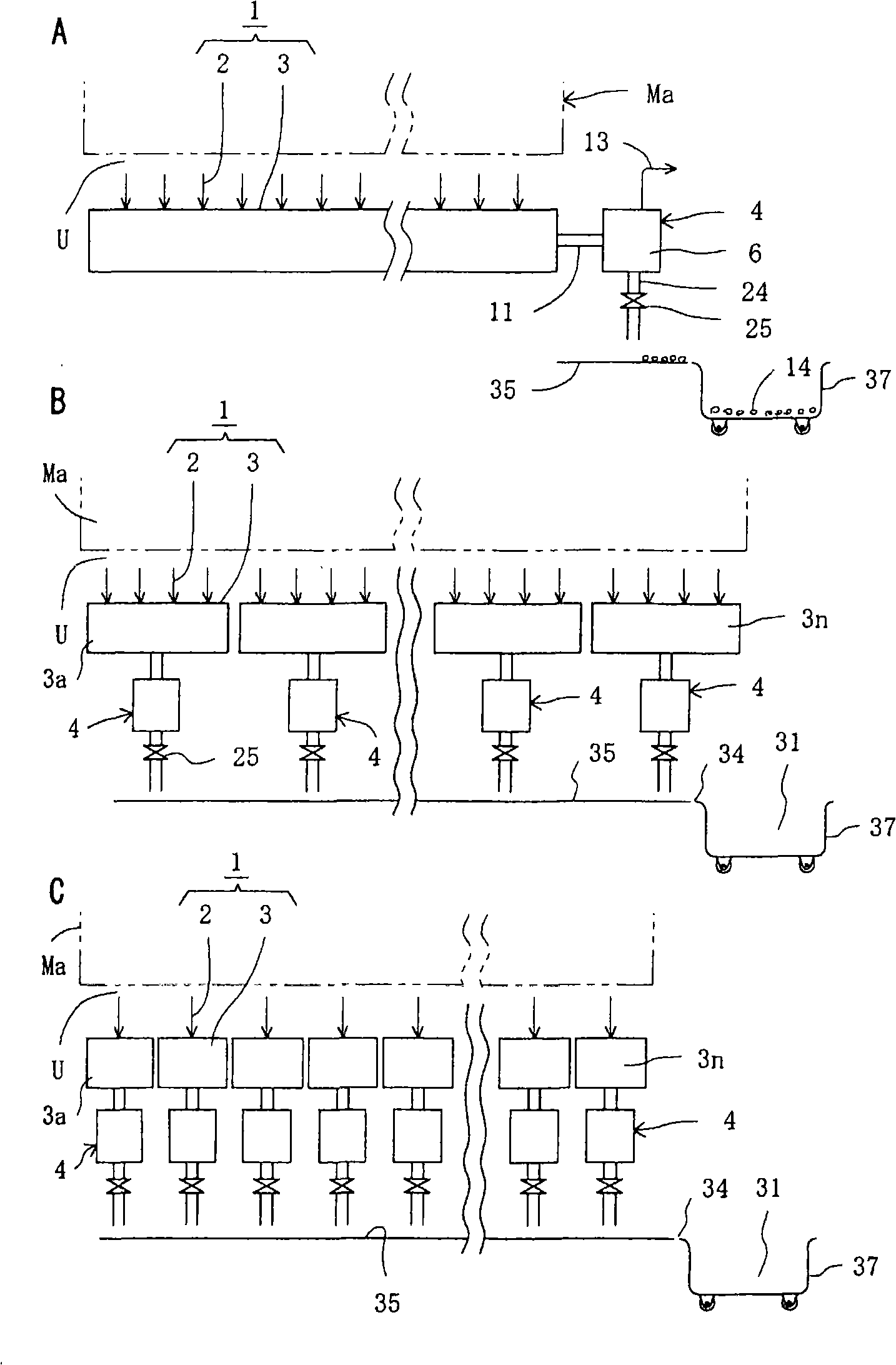

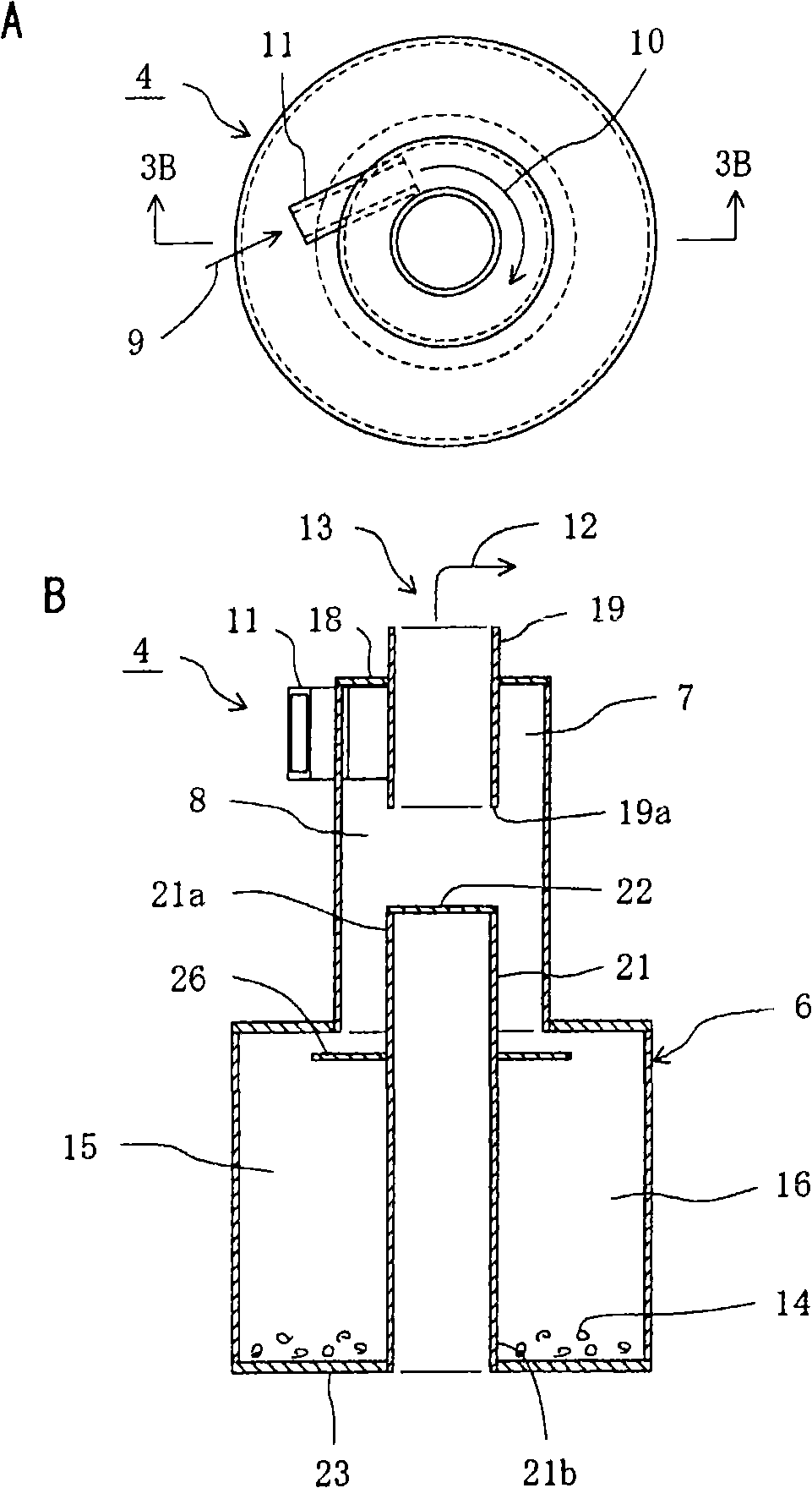

[0026] Hereinafter, the cotton collection processing system in the textile machine according to an embodiment of the present invention will be described with reference to the drawings.

[0027] First, regarding an example of a textile machine using the cotton collection processing system according to an embodiment of the present invention, according to FIGS. 6 to Figure 8 The illustrated textile machine M will be described. The spinning machine M has a structure in which a plurality of spinning units U (hereinafter referred to as spindles U) are arranged in one direction on one machine table Ma. In the spinning machine M, first, the sliver L is sent to the drafting device D, and the spun yarn Y is formed by the spinning section Sp. Then, the spun yarn Y passes through the grip roller Rn, the thick yarn remover Z, and the like, and is wound around the winding section W to form a package PW. In the figure, P is the splicing cart for splicing. The splicing trolley P moves along the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com