Automatic control system for seed cotton

An automatic control system and seed cotton technology, applied in the field of cotton processing machinery, can solve problems such as blockage of the cleaning machine, stoppage of the gin feeding the seed cotton, and influence on normal production, and achieve the effect of avoiding malignant accidents and uniform feeding of the seed cotton

Inactive Publication Date: 2010-11-24

安徽省振宇机械自动化有限公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Due to the uneven feeding of seed cotton by hand, the seed cotton enters the cleaning machine more and sometimes less, which reduces the cleaning efficiency of the cleaning machine

It also often occurs that the cleaning machine is blocked due to the excessive amount of seed cotton fed, and the gin stops rolling because the amount of seed cotton fed is too small, which seriously affects normal production.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

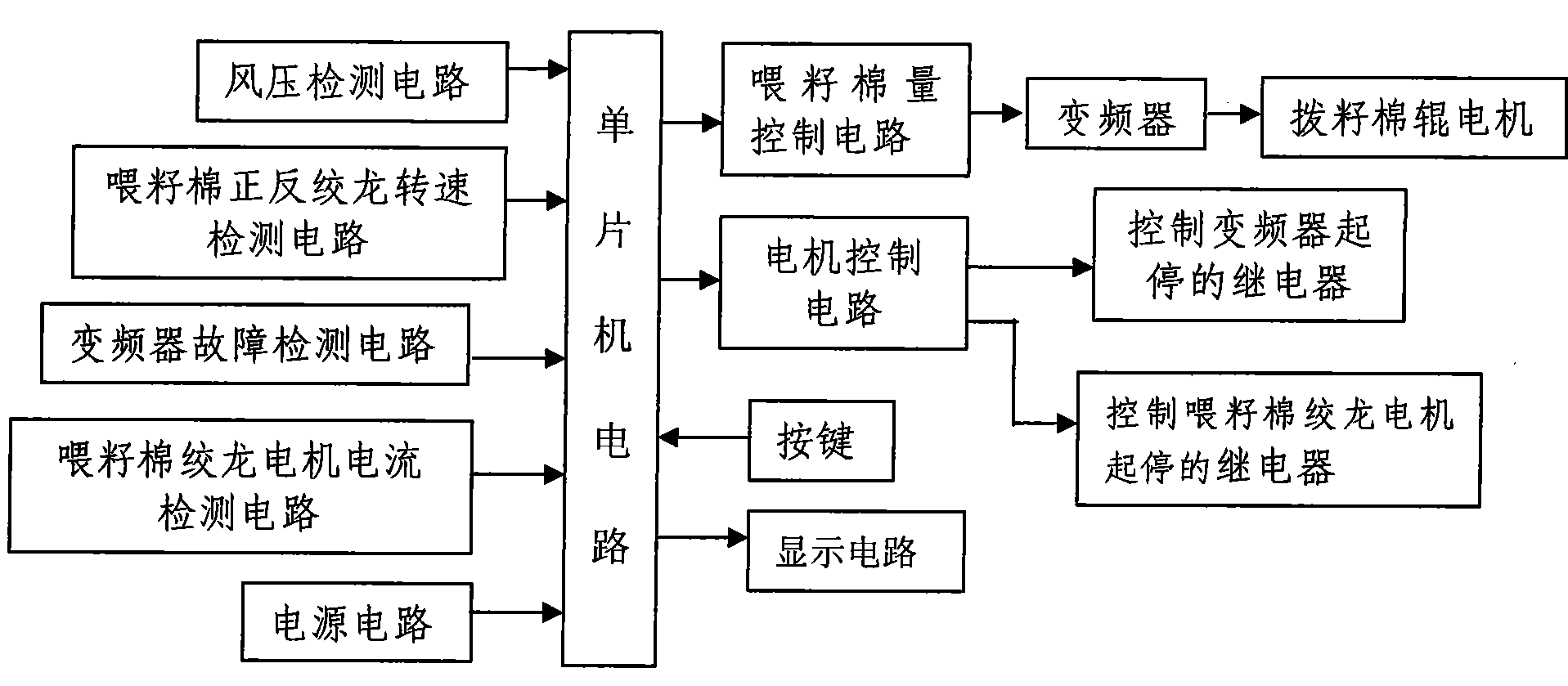

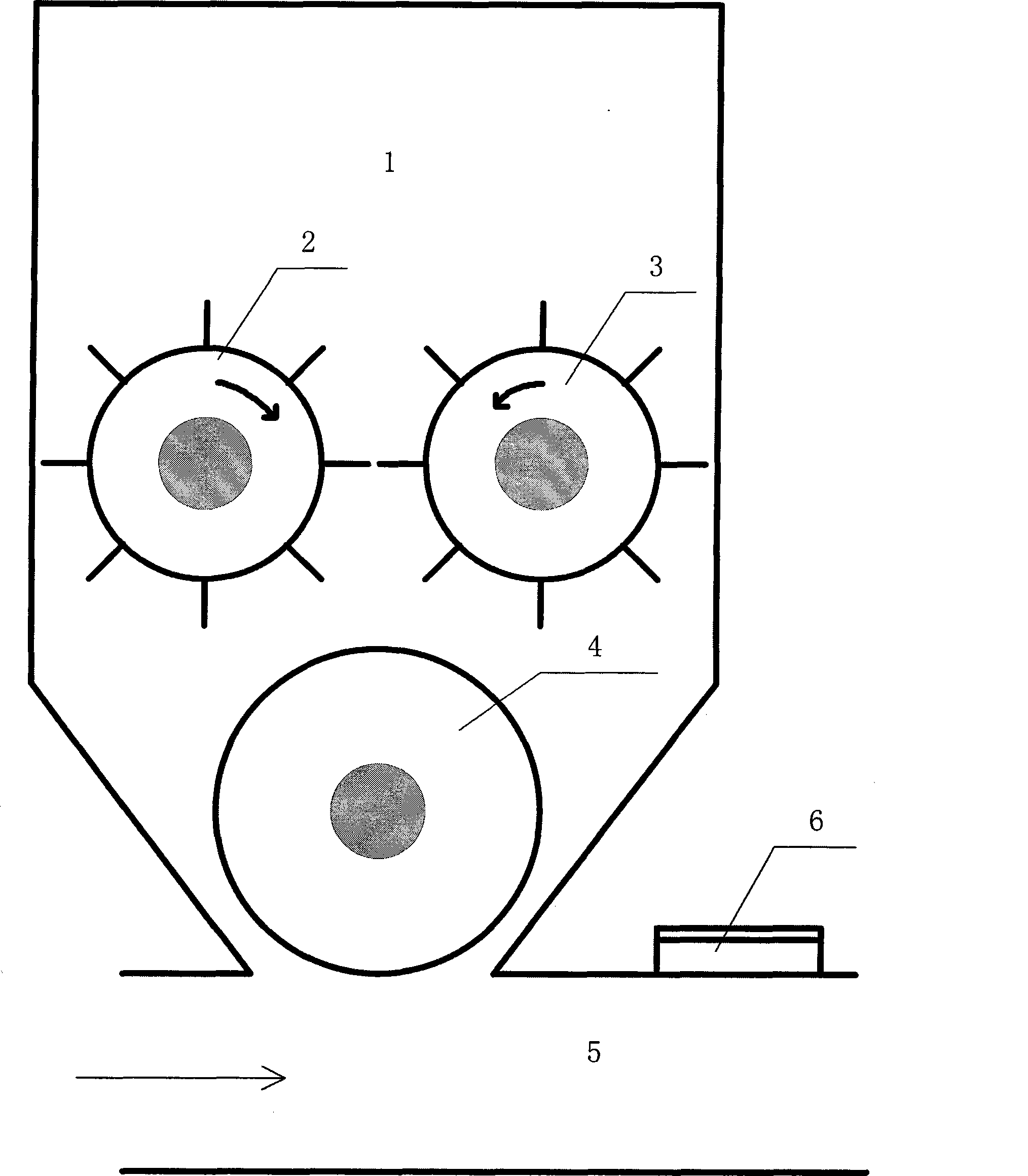

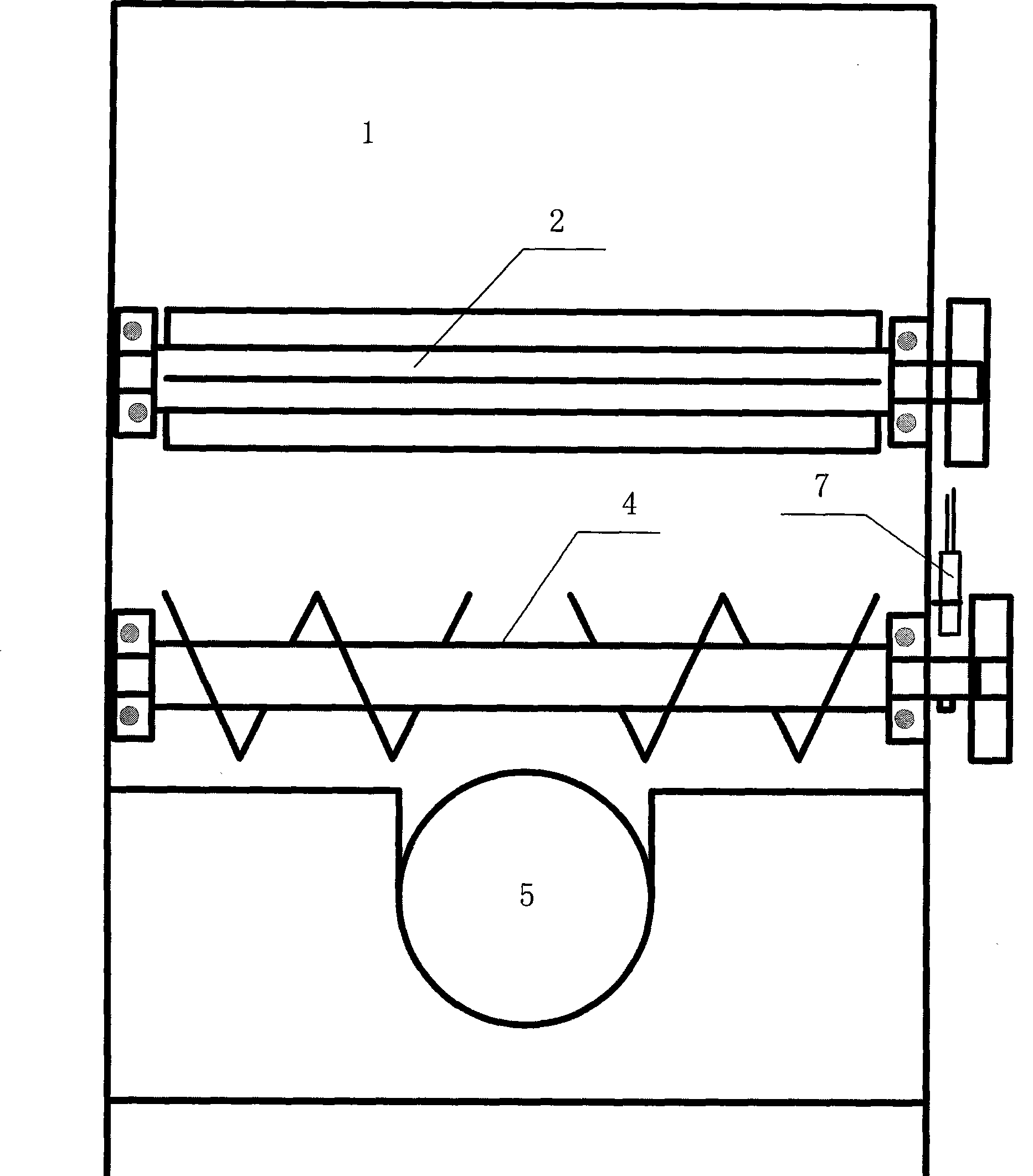

The invention is a seed cotton feeding automatic control system which belongs to the field of cotton processing machinery. The system consists of a seed cotton poking roller motor, a seed cotton feeding screw conveyer motor, a driving device, a seed cotton poking roll, positive and negative seed cotton feeding screw conveyers and a frequency converter; and the seed cotton poking roll motor is connected with a frequency conversion output. The system is characterized in that the seed cotton poking roll motor, the seed cotton feeding screw conveyer motor and the frequency converter are connectedwith a control circuit; the control circuit consists of a power source, a detection circuit for detecting the rotation rate of positive and negative seed cotton feeding screw conveyers, frequency converter faults, wind pressure and the current of the seed cotton feeding screw conveyer motor, a single-chip microcomputer circuit, a control circuit controlling seed cotton feeding amount and the motors and keys and a display circuit. The seed cotton feeding control system adopts the advanced single-chip microcomputer technology and the sensor technology to monitor the rotation rate of the positive and negative seed cotton feeding screw conveyers, the wind pressure, and the current of the seed cotton feeding screw conveyer motor of the seed cotton feeding operation system in real time, automatically adjusts the seed cotton feeding amount according to the monitoring value, and realizes automatic control, unmanned operation, evenly seed cotton feeding and no serious accident.

Description

Seed Cotton Feeding Automatic Control System Technical field: The invention belongs to the field of cotton processing machinery and relates to an automatic control system for feeding seed cotton. technical background: In the current cotton processing technology in our country, the airflow conveying method is mainly used for the seed cotton entering the processing equipment in the freight yard, and the airflow conveying pipeline for feeding the seed cotton is entirely dependent on manpower. Generally, a medium-sized ginning factory needs 8-10 strong laborers per shift to meet the production load. Not only is the labor intensity high, but the environmental sanitation conditions are also poor. Due to the uneven artificial feeding of seed cotton, the seed cotton enters the cleaning machine more and sometimes less, which reduces the cleaning efficiency of the cleaning machine. It also often occurs that the cleaning machine is blocked due to the excessive amount of seed cotton ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G05B19/042D01B1/02D01G9/16

Inventor 左敬东左振

Owner 安徽省振宇机械自动化有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com