Moving dust-preventing apparatus for silo feed inlet

A feeding port and silo technology, which is applied to the field of mobile dust sealing devices for industrial silos feeding ports, can solve the problems of splashes occupying the road, polluting the working environment, dust pollution, etc. Energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below according to accompanying drawing.

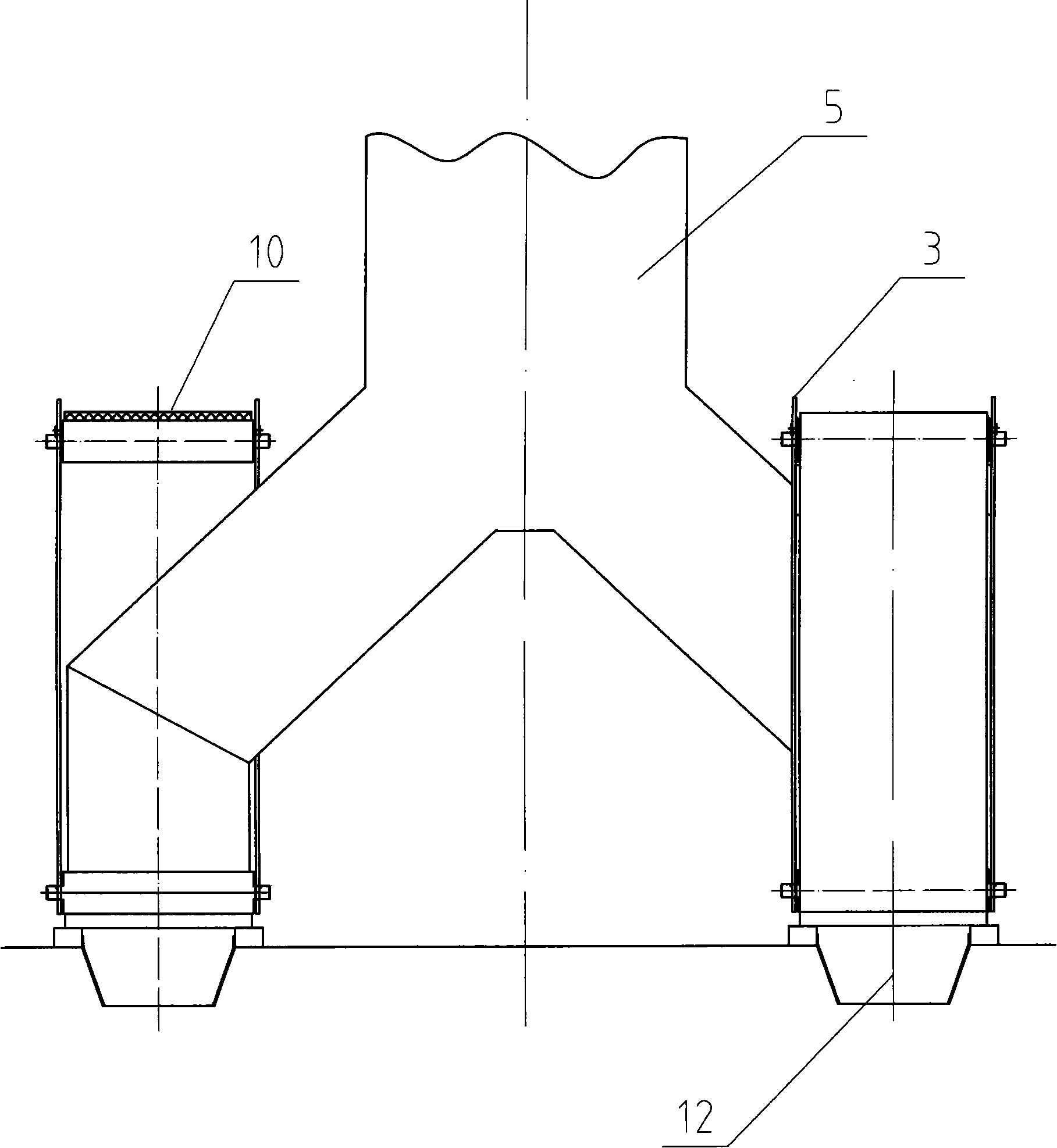

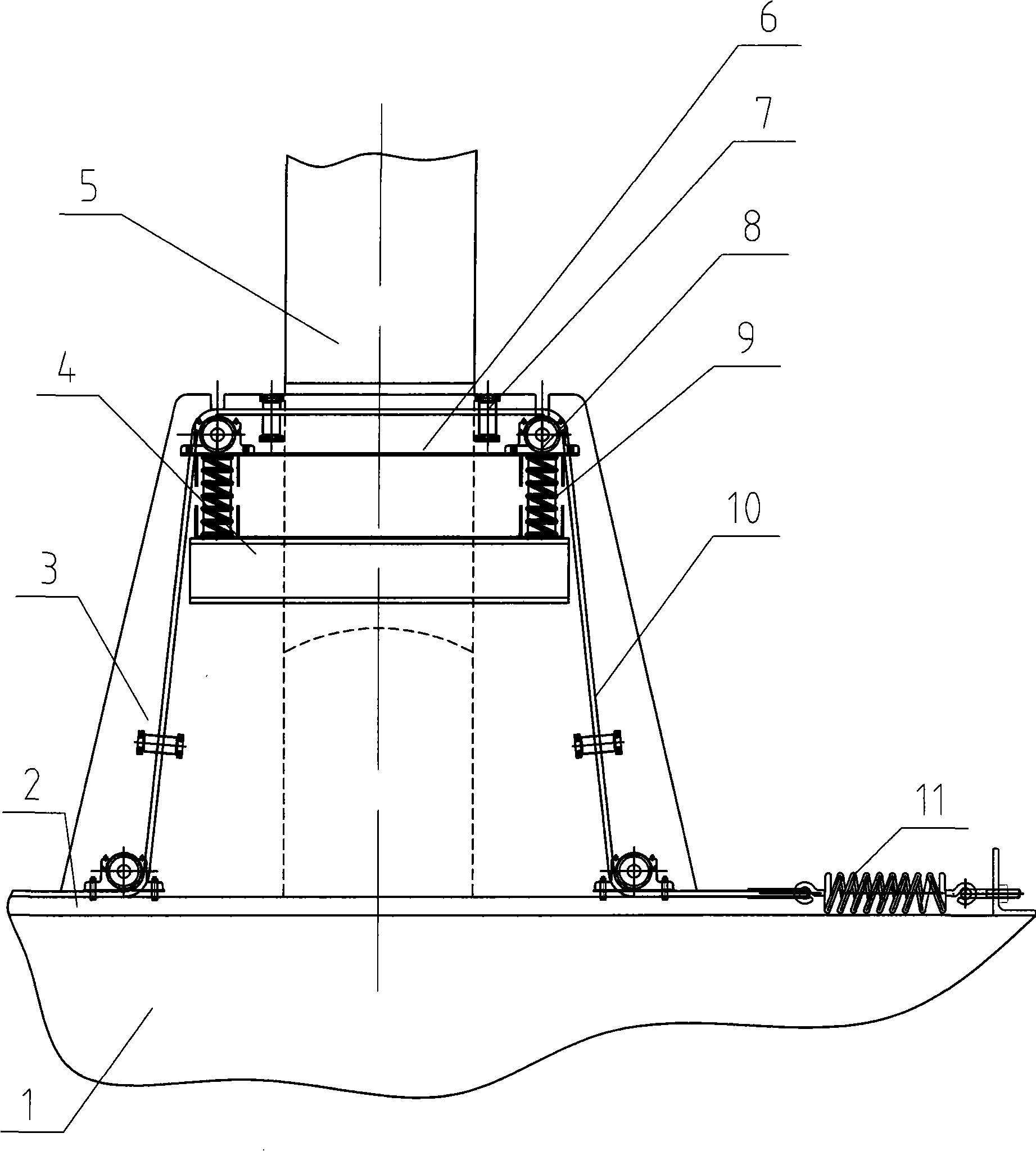

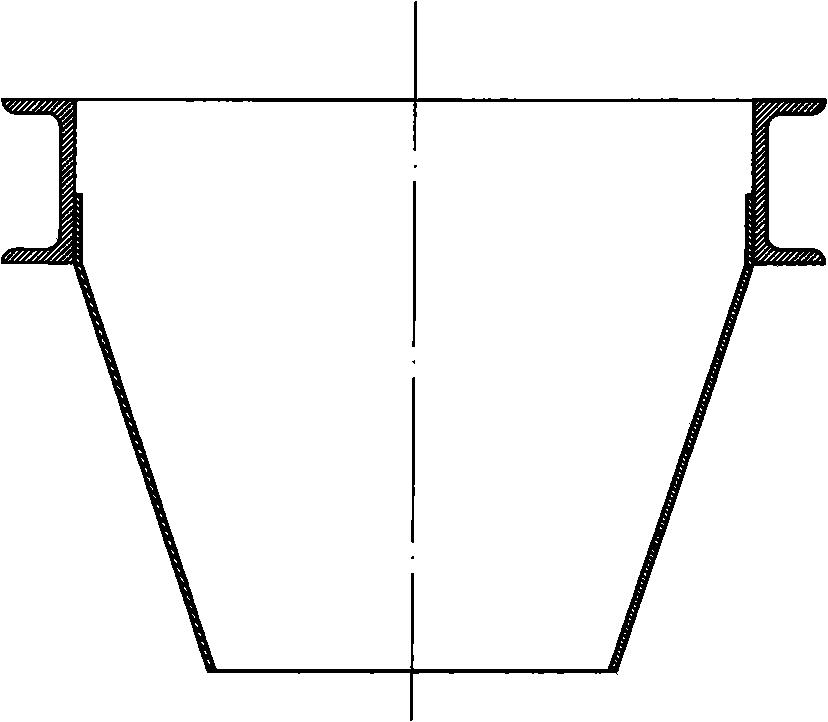

[0018] The dust-sealing device for the feeding port of the silo shown in the accompanying drawings includes a feeding port 1 for the silo, a platform for the silo 2, a bracket 3, a fixed base 4, a feeding trolley discharge port 5, a moving base 6, an anti-deflection wheel 7, a roller Shaft 8, spring 9, adhesive tape 10, screw rod tensioning structure 11 and splash-proof groove 12. attached figure 1 The feeding trolley discharge port 5 shown is a double fork, which extends obliquely from the inner walls of the brackets 3 on both sides and is connected to each other. Oral tube shape. A trapezoidal splash-proof groove 12 is arranged inside the silo platform 2, and the splash-proof groove 12 is sheathed on the periphery of the discharge port 5 of the feeding trolley. The splash produced when the material falls from the discharge port 5 of the feeding trolley slides down to the feed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com