Diversion shield tunnel traversing new sea dyke and foundation treatment method thereof

A technology for water diversion shield tunnel and foundation treatment, applied in tunnels, tunnel linings, underground chambers, etc., can solve the problems of slow consolidation speed, high compressibility, poor grouting effect, etc., and improve the lateral stress state. , the effect of preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

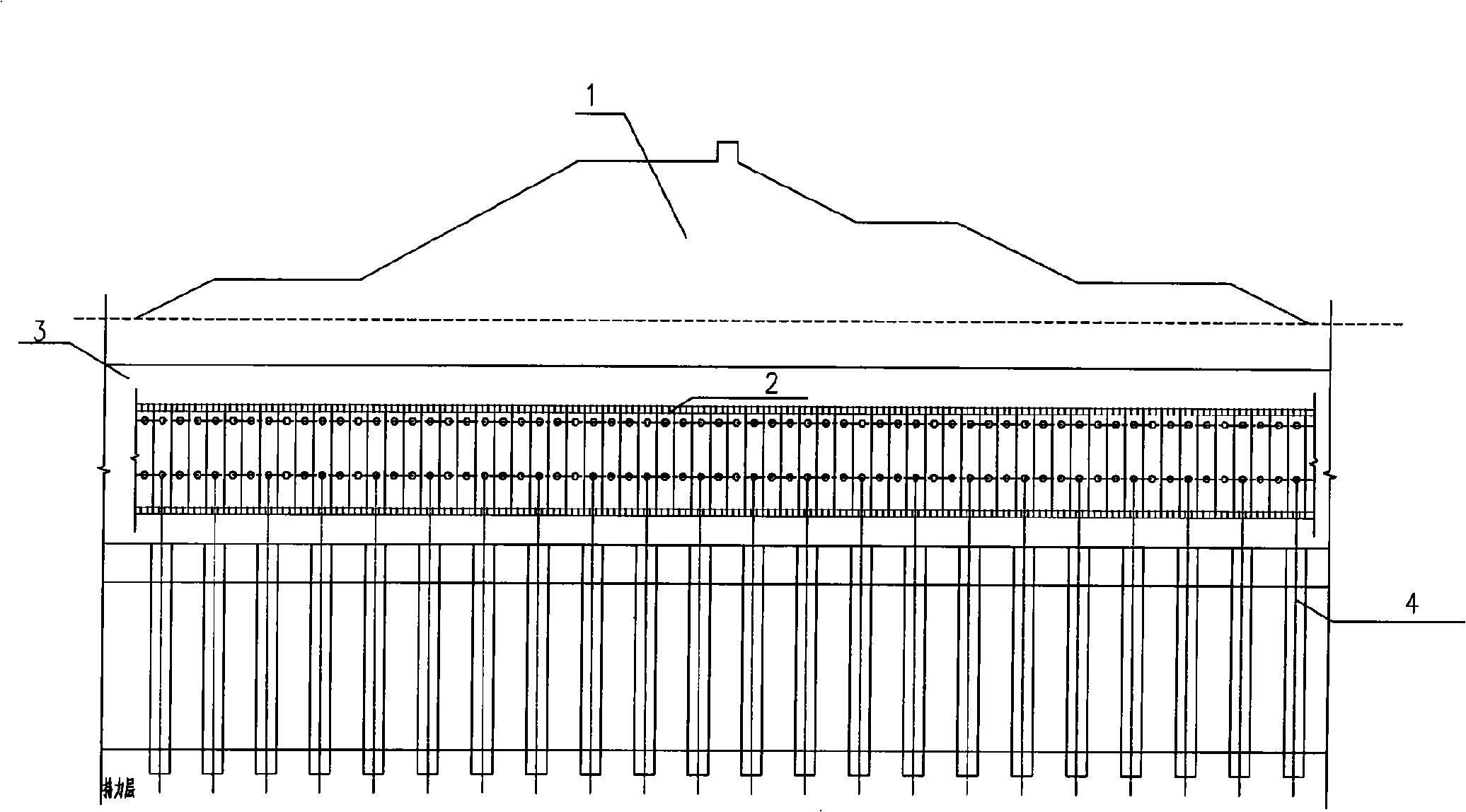

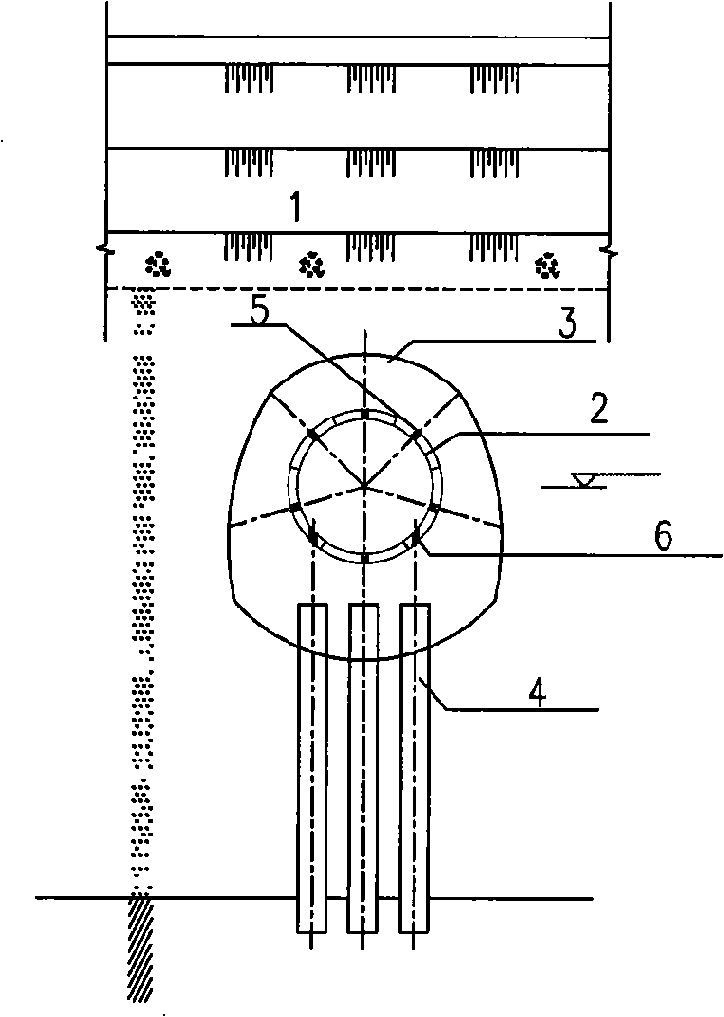

[0011] The present invention will be described in further detail below in conjunction with the accompanying drawings. figure 1 , 2 As shown, the water diversion shield tunnel 2 passing through the newly-built seawall 1 according to the present invention is assembled by a plurality of annular segments through bolts, and the corresponding positions of the segments are preset with compaction grouting holes 5 and High-pressure jet grouting pile operation hole 6; a plurality of high-pressure jet grouting piles 4 are arranged at a certain distance away from the bottom of the segment to form a transition layer, and pass compaction in the mud around the water diversion shield tunnel formed by the segment A reinforcement layer 3 is formed by grouting.

[0012] The water diversion shield tunnel is composed of six circumferential segments 2 spliced in pairs by high-strength bolts to form an overall structure, and the 4 high-pressure rotary grouting piles are separated from the bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com