Gravity engine

An engine and gravity technology, applied in the direction of engines, machines/engines, mechanisms that generate mechanical power, etc., can solve problems such as failure to create, large frictional resistance, and small quantity, so as to overcome the unstable power of a single machine and increase output The effect of energy, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] In addition to Figure 5a, 8, in the following figures, due to the limitation of the drawing, in order to make R 1 Sharp images in visual range, R 2 / R 1 The ratios are all plotted as η<7.

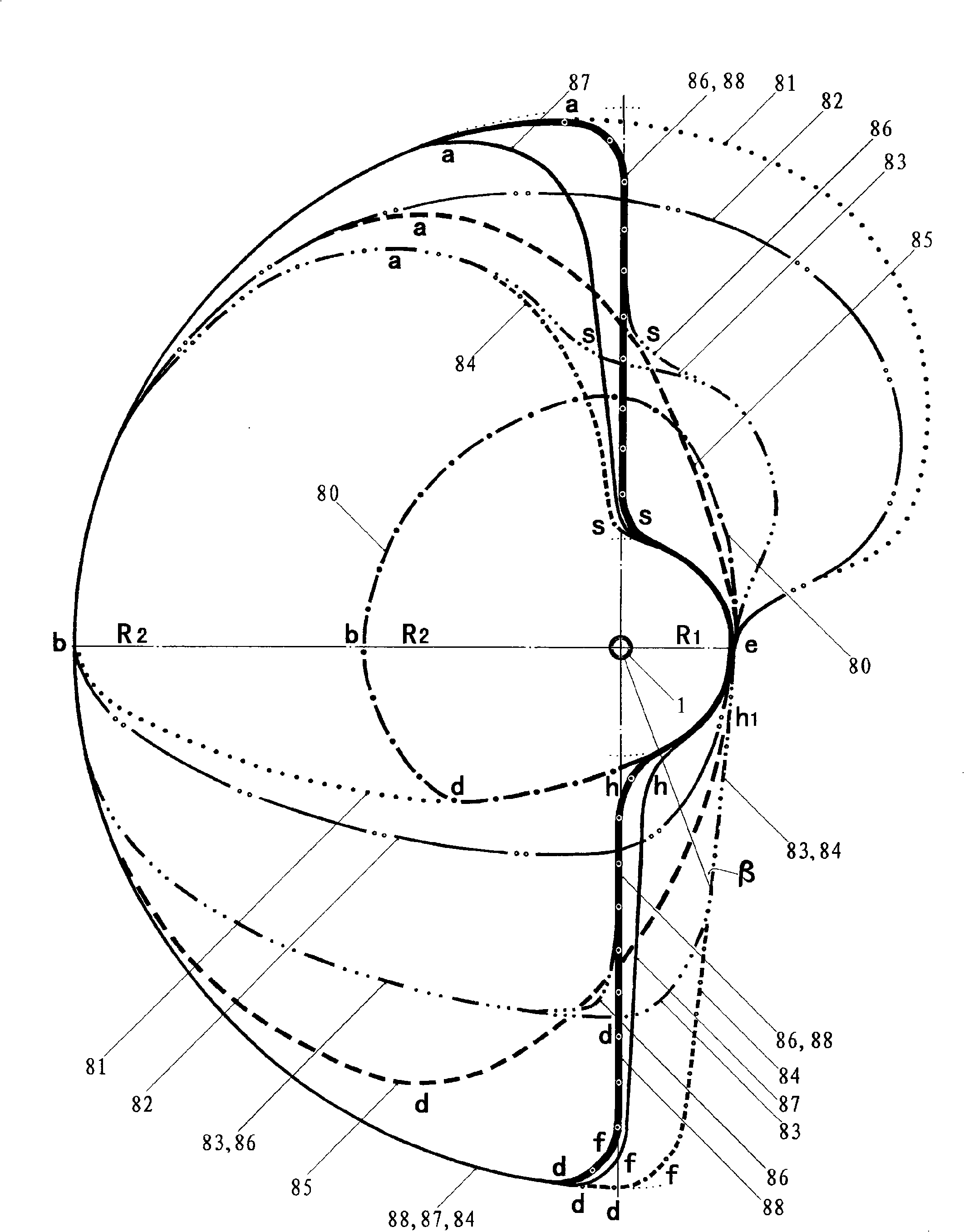

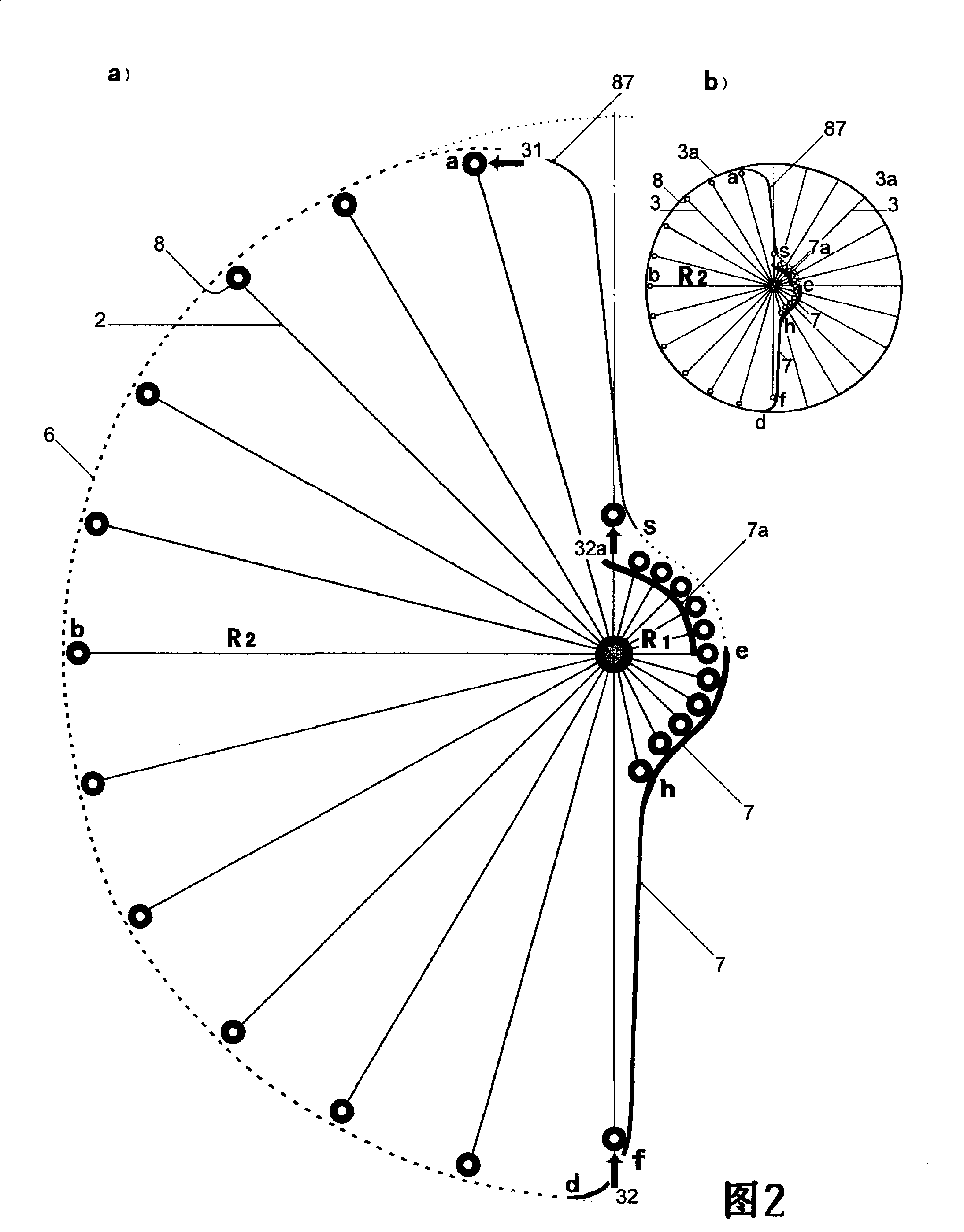

[0060] figure 1 Nine types of stator rails 80-88 involving only straight-spoke-rod 2-type eccentric rotors are given.

[0061] Guide rails 81 and 82 have an inflection point at e, and their uplink e-a section occupies a large area of the first quadrant, that is, the resistance moment M 1 large; while the antisymmetric third quadrant has a small area of work, and the driving moment of gravity M 2 necessarily small.

[0062] If there are inflection points h and s, the small eccentric uplink segment becomes d-f-h-e-s-a.

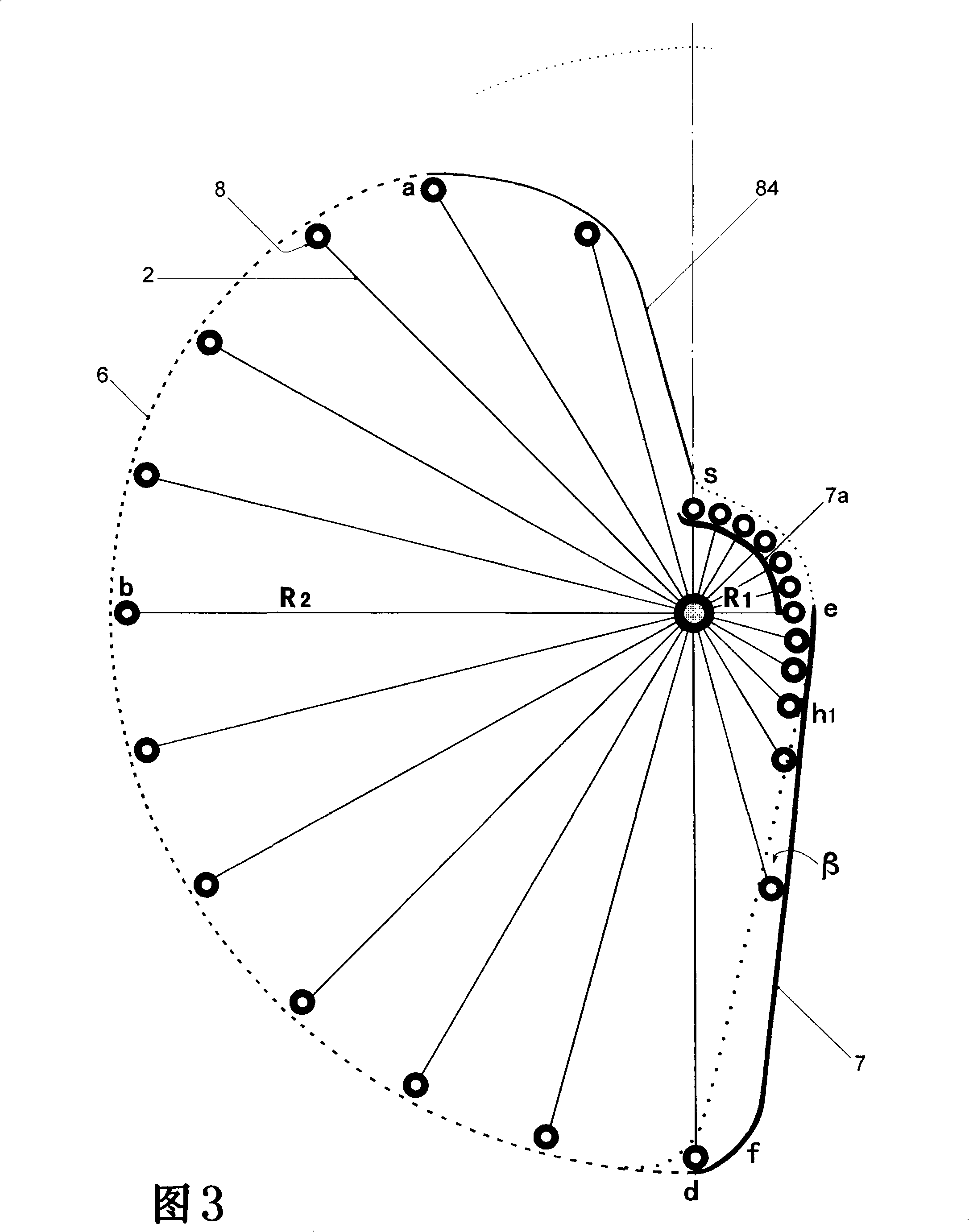

[0063] The guide rails 83 and 84 (see FIG. 3 ) have no lower point of inflection h, but have an upper point of inflection s.

[0064] The guide rail 85 is a well-known vertically symmetrical arc without an inflection point.

[0065] All guide rails 83-85 w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com