Efficient vacuum oil filter

A vacuum oil filter, high-efficiency technology, applied in the direction of filtering and thickening suspension liquid separation, liquid separation, chemical instruments and methods, etc. increase and other problems to achieve the effect of promoting uniform suction, reducing energy consumption, and increasing processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

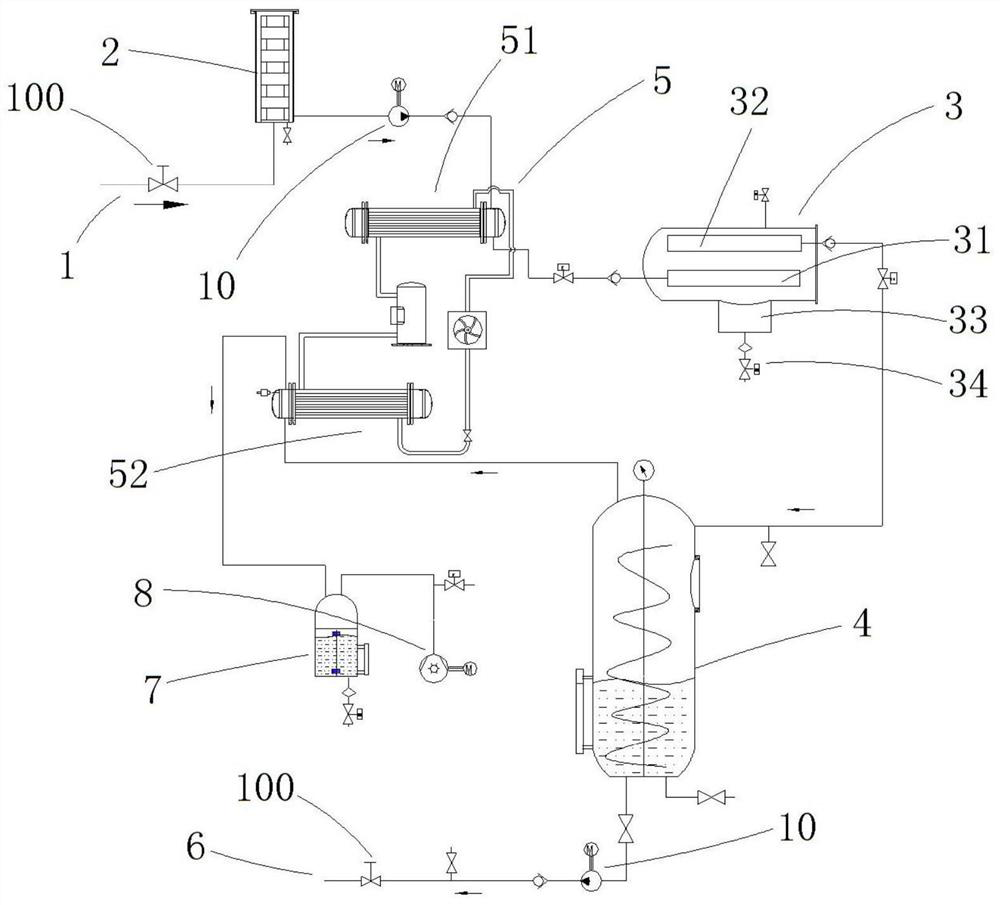

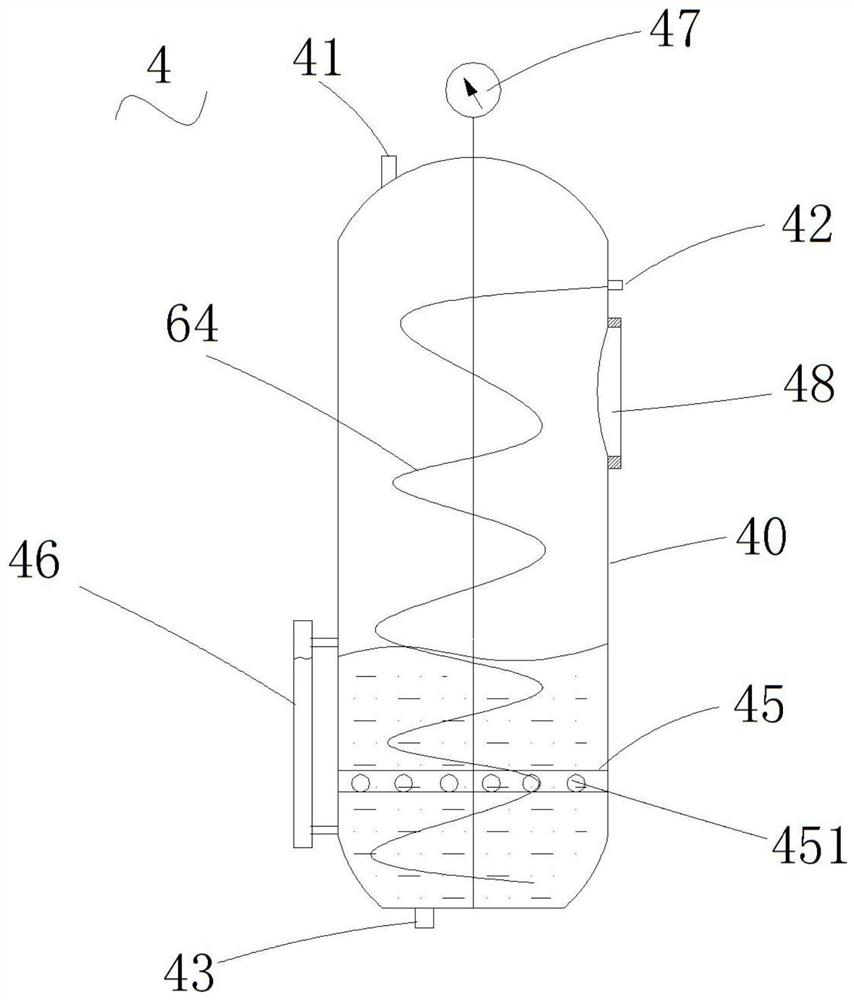

[0030] See Figure 1 to Figure 3 , the high-efficiency vacuum oil filter shown in an embodiment of the present invention includes: an oil inlet pipeline 1, an oil suction filter 2, a coalescing separator 3, an evaporator 4, a heat pump system 5, and an oil outlet pipeline 6, wherein the coalescing separator 3 is provided with a coalescing filter element 31 and a separation filter element 32, which is an existing structure and will not be described in detail here. The oil enters the oil suction filter 2 from the oil inlet line 1, and after removing the insoluble impurities, it is heated by the heat pump system 5 and enters the coalescing separator 3, and most of the water in the oil is removed by the principle of coalescence separation, Moisture is stored in the water storage type 33 and discharged from the drain pipe 34 . Then the oil enters the evaporator 4 for further water removal, the water vapor in the evaporation process is condensed by the heat pump system 5 , and the ...

Embodiment 2

[0041] See Figure 4, the structure of the high-efficiency vacuum oil filter of this embodiment is basically the same as that of Embodiment 1, the difference is that: in this embodiment, the oil outlet pipeline 6 is also connected to the coalescing separator 3 . Specifically, the oil outlet pipeline 6 includes a main pipeline 61, an oil pump 10 arranged on the main pipeline 61, a first pipeline 62 connecting the oil outlet and the main pipeline 61, and a second pipeline 62 connecting the coalescence separator 3 and the main pipeline 61. pipeline63. Valve structures 100 are respectively provided on the main pipeline 61 , the first pipeline 62 and the second pipeline 63 .

[0042] This design method can facilitate the replacement of the filter element (coalescing filter element 31 and / or separation filter element 32) for the coalescer separator 3. When the filter element needs to be replaced, the residual oil in it can be pumped out through the second pipeline.

Embodiment 3

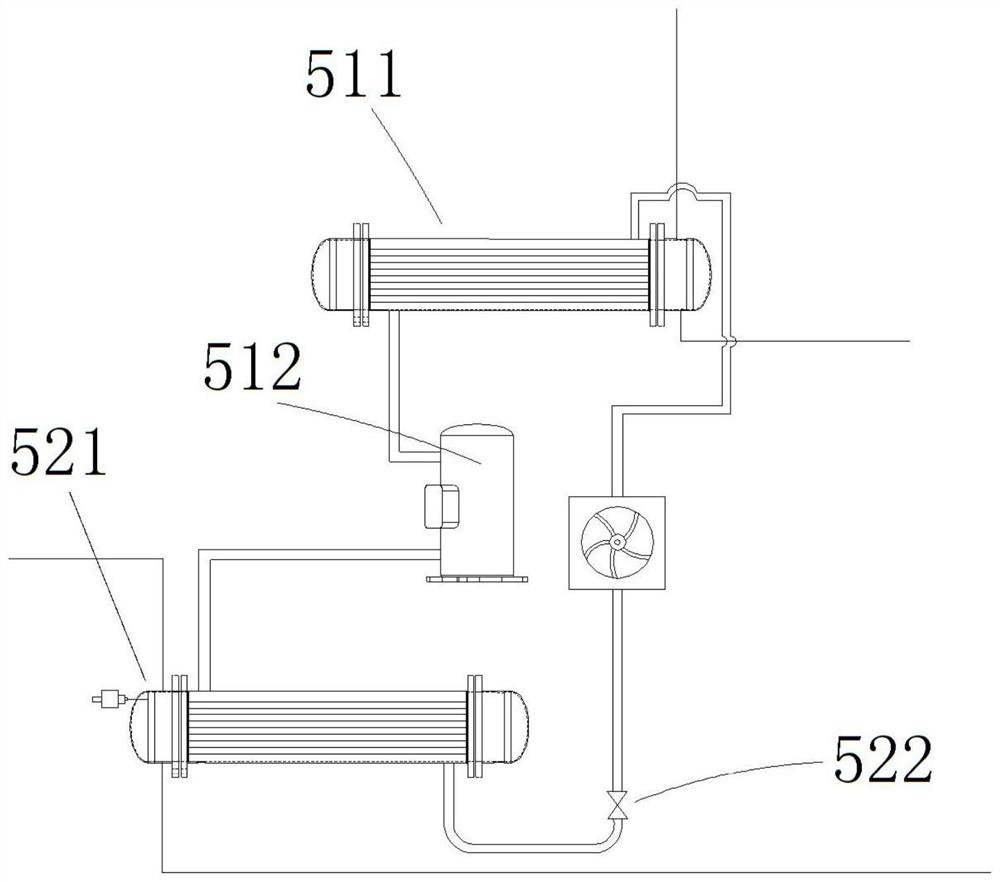

[0044] See Figure 5 to Figure 8 , the structure of the high-efficiency vacuum oil filter of this embodiment is basically the same as that of Embodiment 1 or Embodiment 2, the difference lies in the heat pump system. In this embodiment, the heat source device further includes an inlet port 13 connected to the second heat exchanger 21, and the compressor unit 12 includes a plurality of compressors 121 arranged in parallel, and each compressor 121 is respectively connected to the inlet port 13 and the first The heat exchanger 11 , the intake port 13 is used to distribute the heat exchange medium into each compressor 121 . In this embodiment, the number of compressors 121 is 4. It is true that in other embodiments, the number of compressors 121 can be selected according to actual needs, and the integrated compressor unit 12 can adopt compression ratios of different sizes. Machine 121 to provide more adjustment stages, so that the cooling capacity output can dynamically match the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com