Integrated high-voltage energy harvesting power supply and its assembly and installation method

An energy harvesting power supply and high-voltage technology, which is applied in the direction of emergency protection circuit devices, circuit devices, emergency protection circuit devices, etc. for limiting overcurrent/overvoltage, can solve the problem of randomness in construction operations, inconsistency of power supply, Inconvenient to use and operate to achieve the effects of low processing and manufacturing costs, simple structure, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

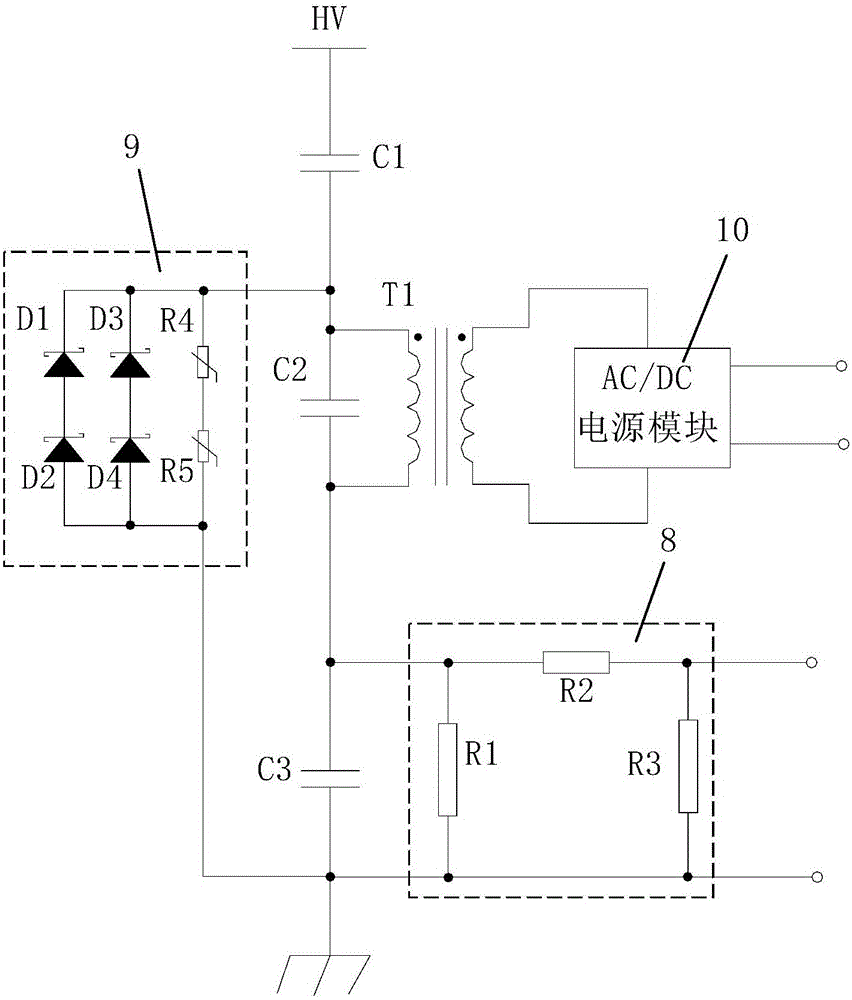

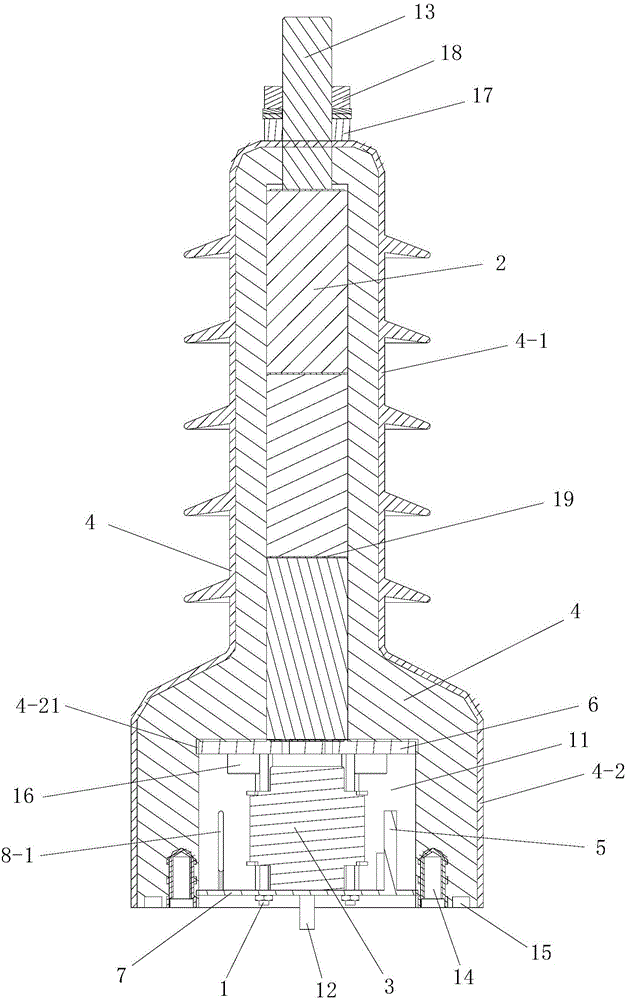

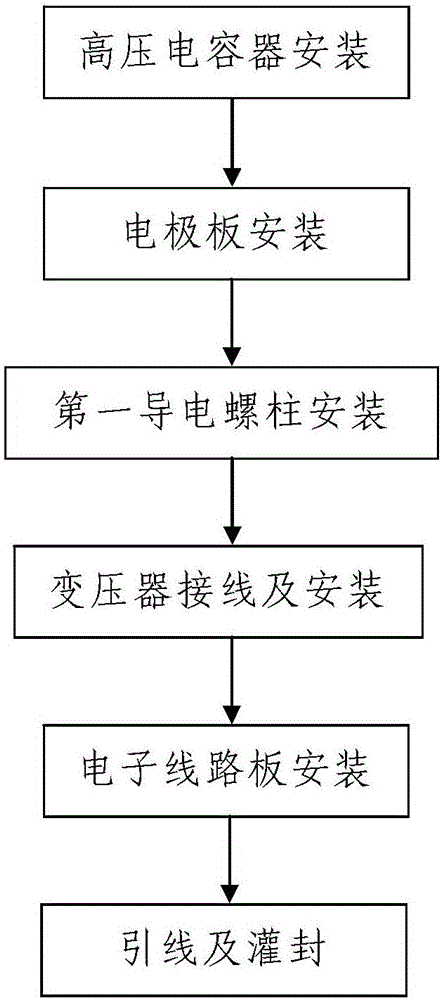

[0068] Such as figure 1 , figure 2 The integrated high-voltage energy harvesting power supply shown includes an insulating outer casing 4, a high-voltage capacitor connected to the power supply and distribution line, a transformer 3 connected to the high-voltage capacitor, and a voltage dividing capacitor connected in parallel with the primary side coil of the transformer 3 5 and the electronic circuit board 7 installed in the insulating outer casing 4, the high-voltage capacitor is connected to the primary side coil of the transformer 3, and the high-voltage capacitor is an energy-taking capacitor 2 or connected in series by a plurality of energy-taking capacitors 2 made. The electronic circuit board 7 is provided with a voltage measurement circuit 8 for real-time measurement of the voltage of the power supply and distribution line, a lightning protection module 9 for protecting the transformer 3 when a lightning accident occurs on the power supply and distribution line, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com