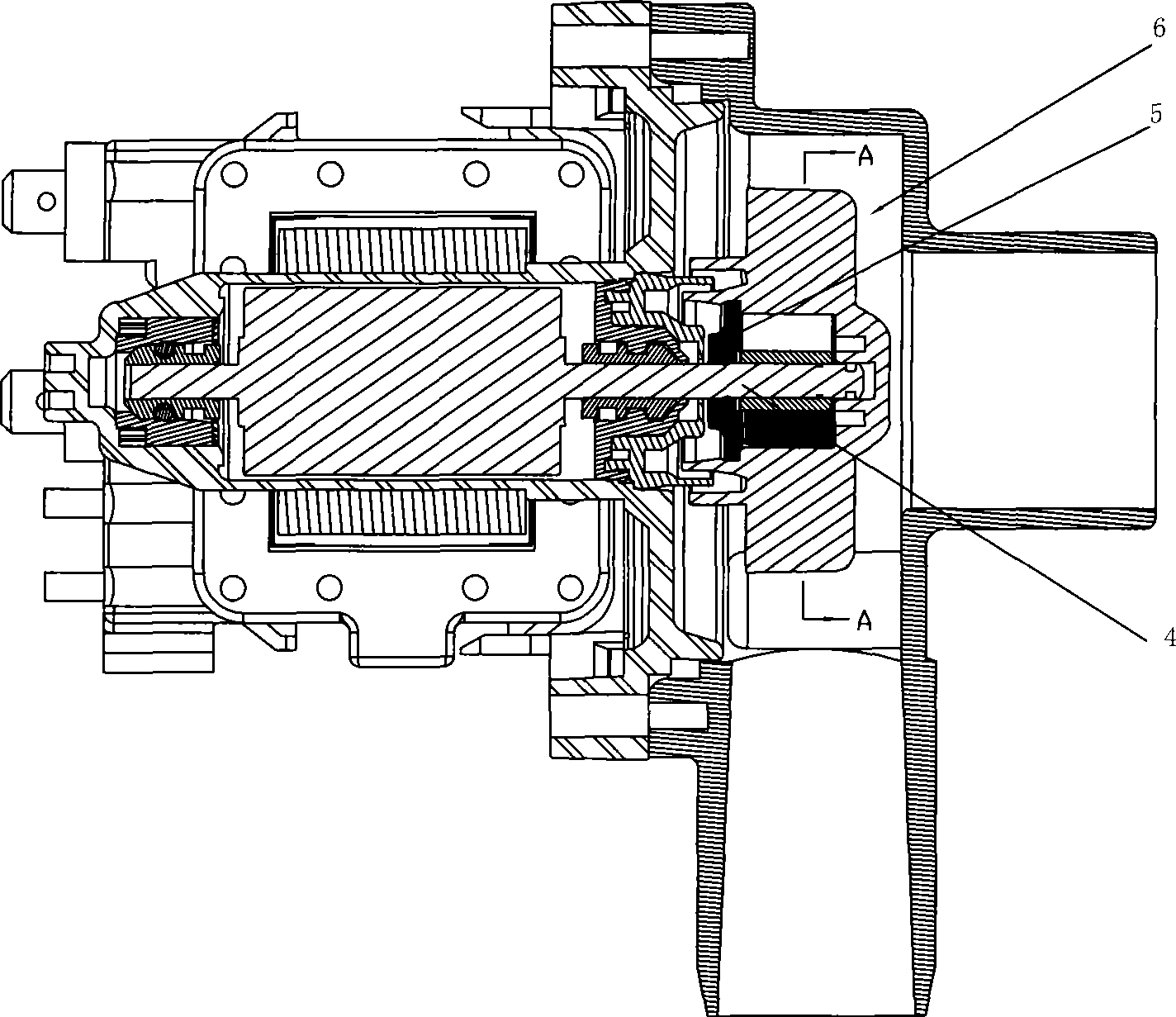

Transmission device between working component and rotor of permanent magnetism synchronous electric machine

A permanent magnet synchronous motor and transmission technology, applied in electromechanical devices, pump devices, electrical components, etc., can solve the problems of noise, limit the free travel or free rotation angle of the shaft sleeve, and shake along the axial direction, and reduce contact noise. , avoid collision or contact phenomenon, avoid the effect of starting a large load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

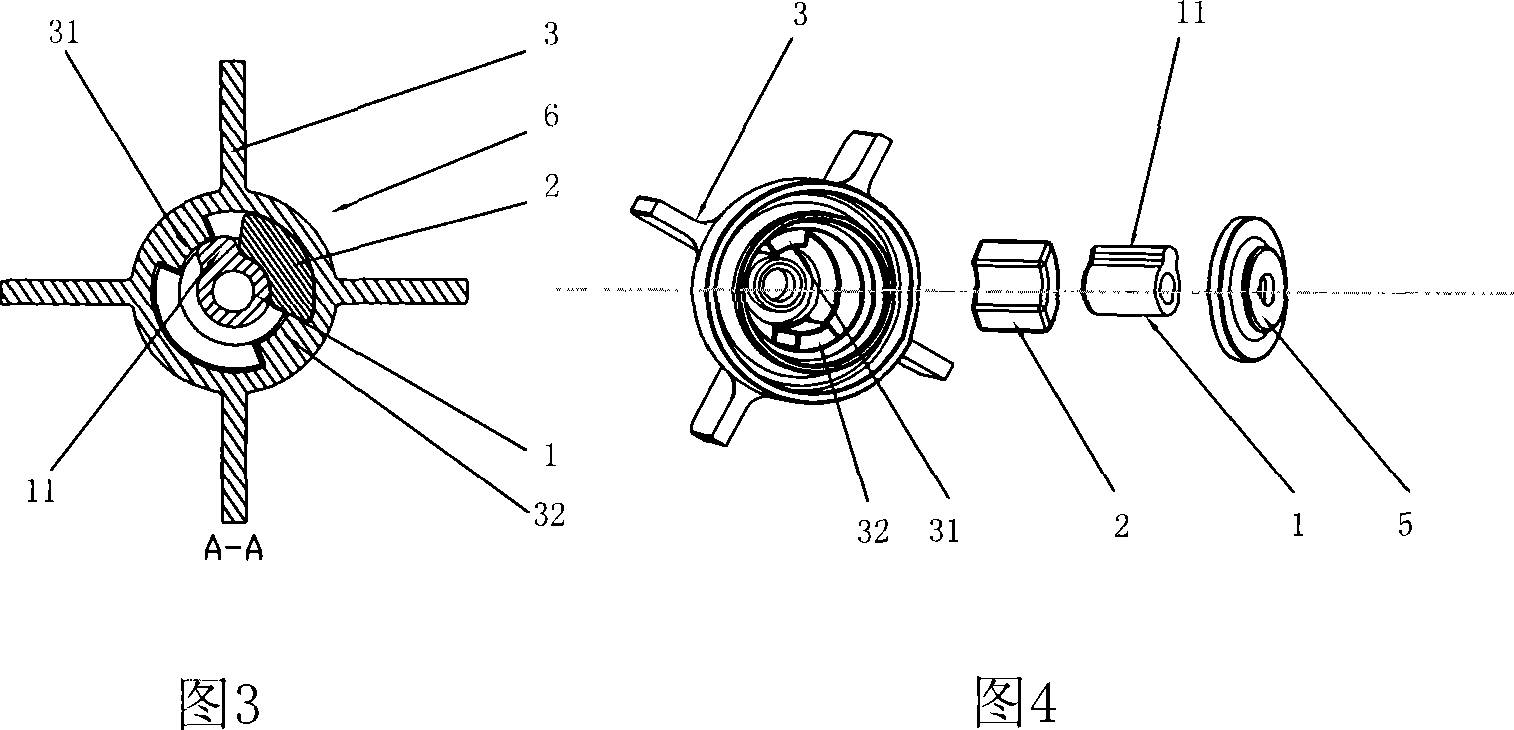

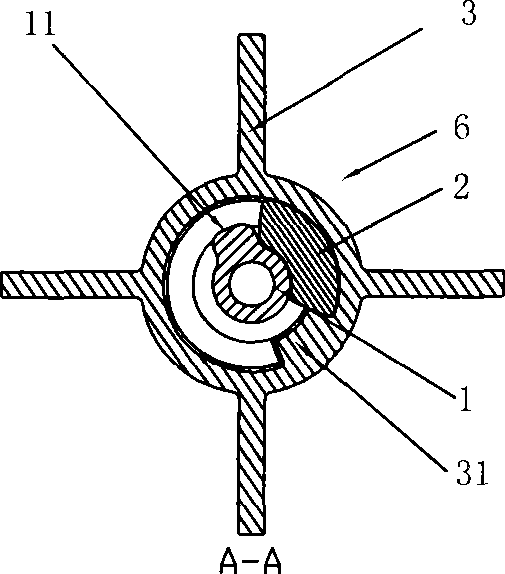

[0057] In order to explain or illustrate the present invention, at first define the following technical terms of the present invention below below:

[0058] Radial refers to the radial direction of the shaft, and axial refers to the axial direction of the shaft;

[0059] The top surface of the activation rib refers to the surface of the highest protrusion of the activation rib protruding from the side wall of the tubular main body of the sleeve;

[0060] The top surface of the limiting rib refers to the highest protruding surface of the limiting rib protruding from the inner wall of the accommodating cavity of the working component;

[0061] The thickness of the shock-absorbing block refers to the difference between the outer arc radius and the inner arc radius of the shock-absorbing block whose cross section is fan-shaped;

[0062] The length of the shock absorber refers to the size of the shock absorber in the direction parallel to the axial direction;

[0063] The length of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com