High-efficiency evaporation type fin heat exchanger

A finned heat exchanger, evaporative technology, applied in the field of finned heat exchangers, can solve the problem of low energy efficiency of the unit, achieve the effect of improving the heat transfer coefficient, improving the heat transfer coefficient, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

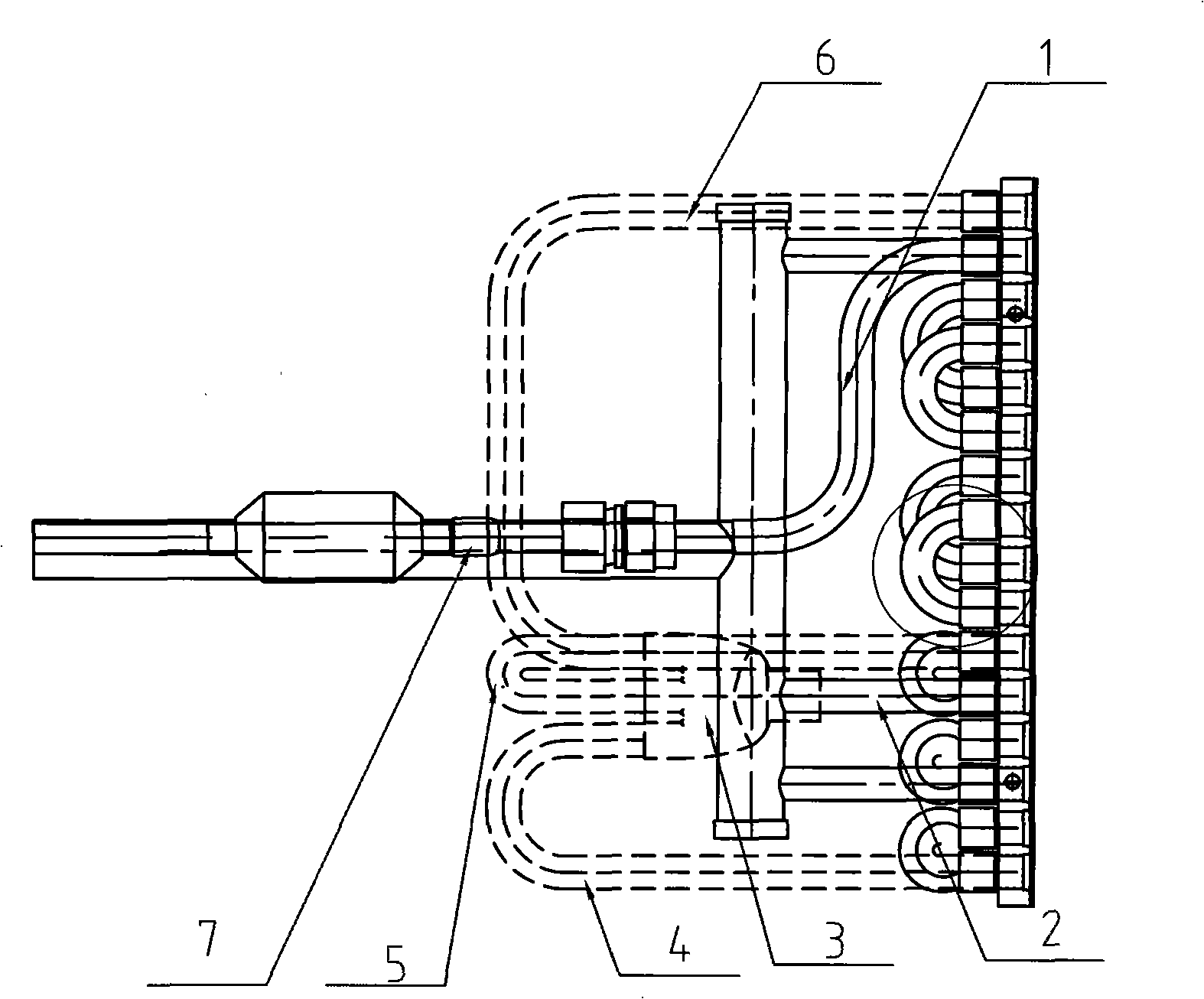

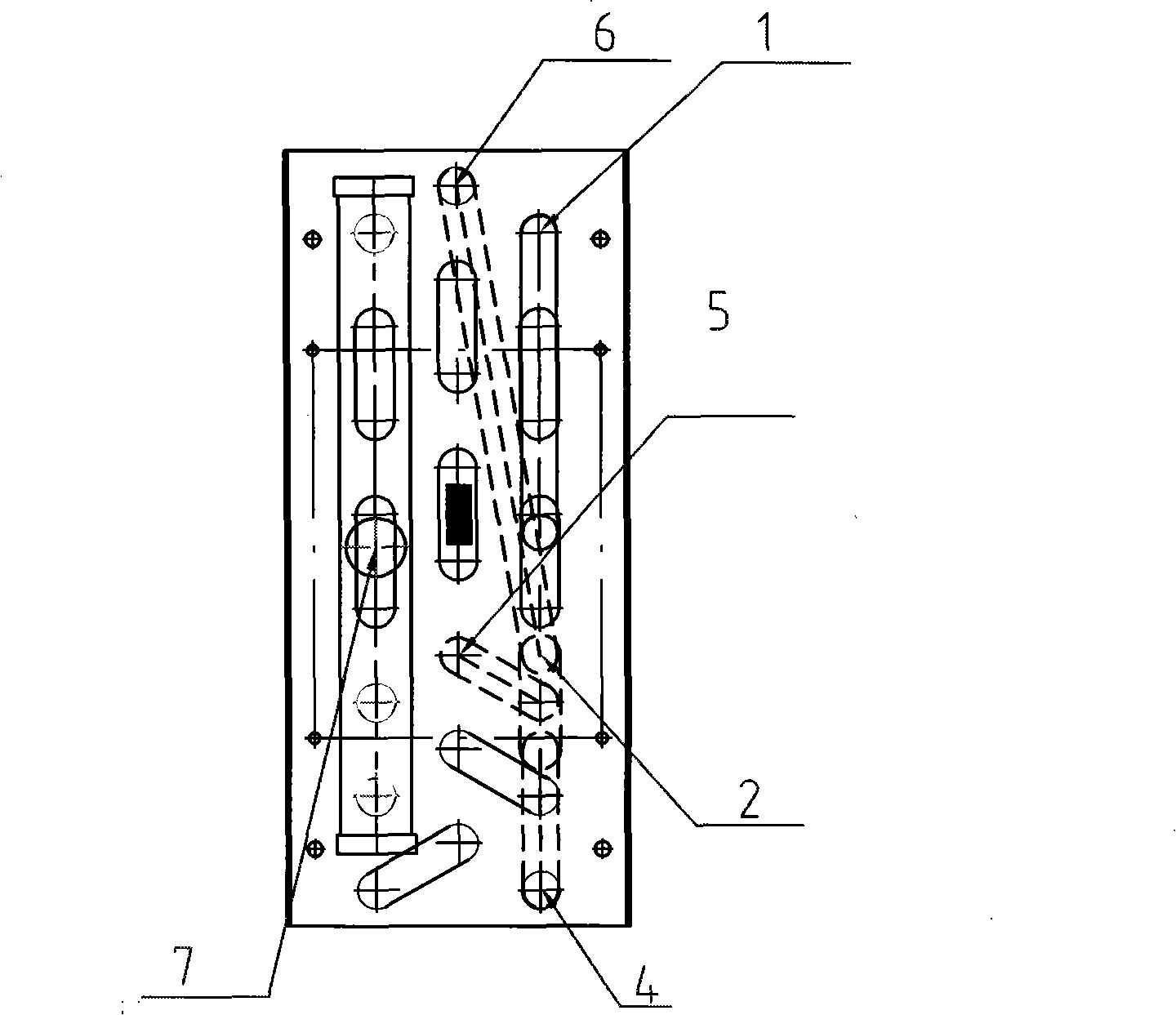

[0014] Now refer to the attached figure 1 .2 To illustrate selected embodiments of the present invention, the following descriptions of the embodiments of the present invention disclosed by those skilled in the art are only exemplary and not intended to limit the solutions of the present invention.

[0015] Such as figure 1 .2 shows a high-efficiency evaporative fin heat exchanger, including a gas collecting pipe 1, a collecting pipe 2 and an air outlet pipe 7, and one end of the collecting pipe 2 is formed by merging the gas collecting pipe 1 through four circuits, The other end of the collecting pipe 2 is divided into a first branch 4, a second branch 5, and a third branch 6 through a trouser-shaped tee 3, wherein each branch merges into an air outlet pipe after passing through the above four circuits 7. It is confirmed by the experimental operation of this unit that it can improve the operating efficiency of the unit by 20%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com