Full-automatic water meter production inspecting method

A production inspection, fully automatic technology, applied in measuring devices, instruments, testing/calibration devices, etc., can solve the problems of single-machine calibration devices, inability to coordinate work with software, cumbersome work, etc., to achieve high accuracy and improve factory calibration efficiency , the effect of avoiding errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

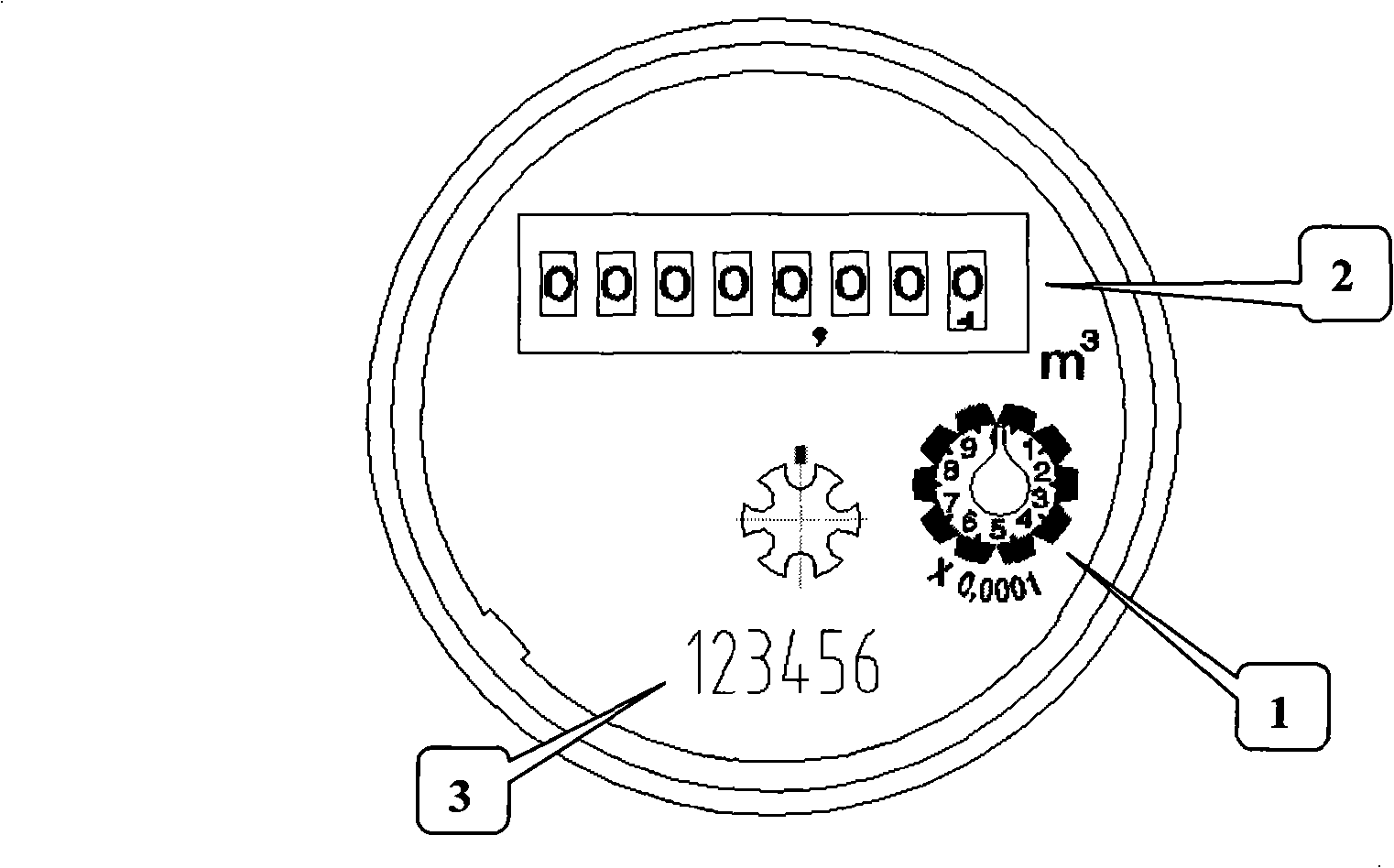

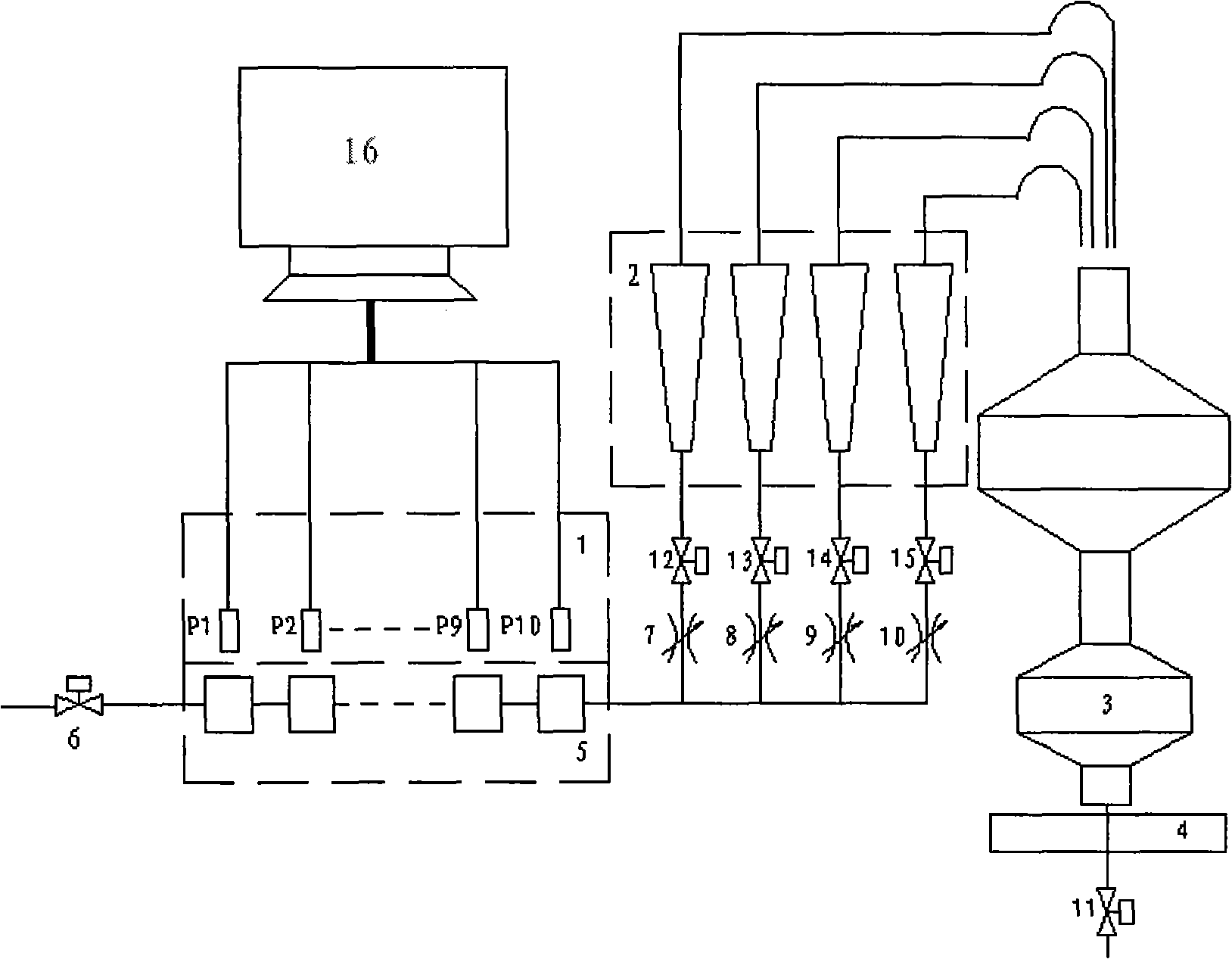

[0019] The production inspection method of fully automatic water meters is to print a string of numbers on the dial of the water meter with laser as the unique ID number of the water meter; in the factory inspection process, the mechanical reading and mechanical ID number of the water meter are digitized and electronicized by using color image processing method ;Use electronic scales and 485 communication methods to realize the electronicization and digitization of standard measurement; after the computer obtains the digital reading of the water meter, the digital identity number and the digital standard measurement, it calculates the measurement error of the water meter, and uses the identity number as the key word to check the water meter. The results are saved in the database and the inspection report is automatically generated.

[0020] Said laser printing a string of numbers on the dial of the water meter as the unique identity number of the water meter: the string of ID n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com