AC trace source DC correcting method

A calibration method and AC voltage source technology, applied in the field of calibration, can solve the problems of many error sources, bulky equipment, and large volume of current transformers, and achieve the effect of fewer standard components, fewer error sources, and simple electrical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

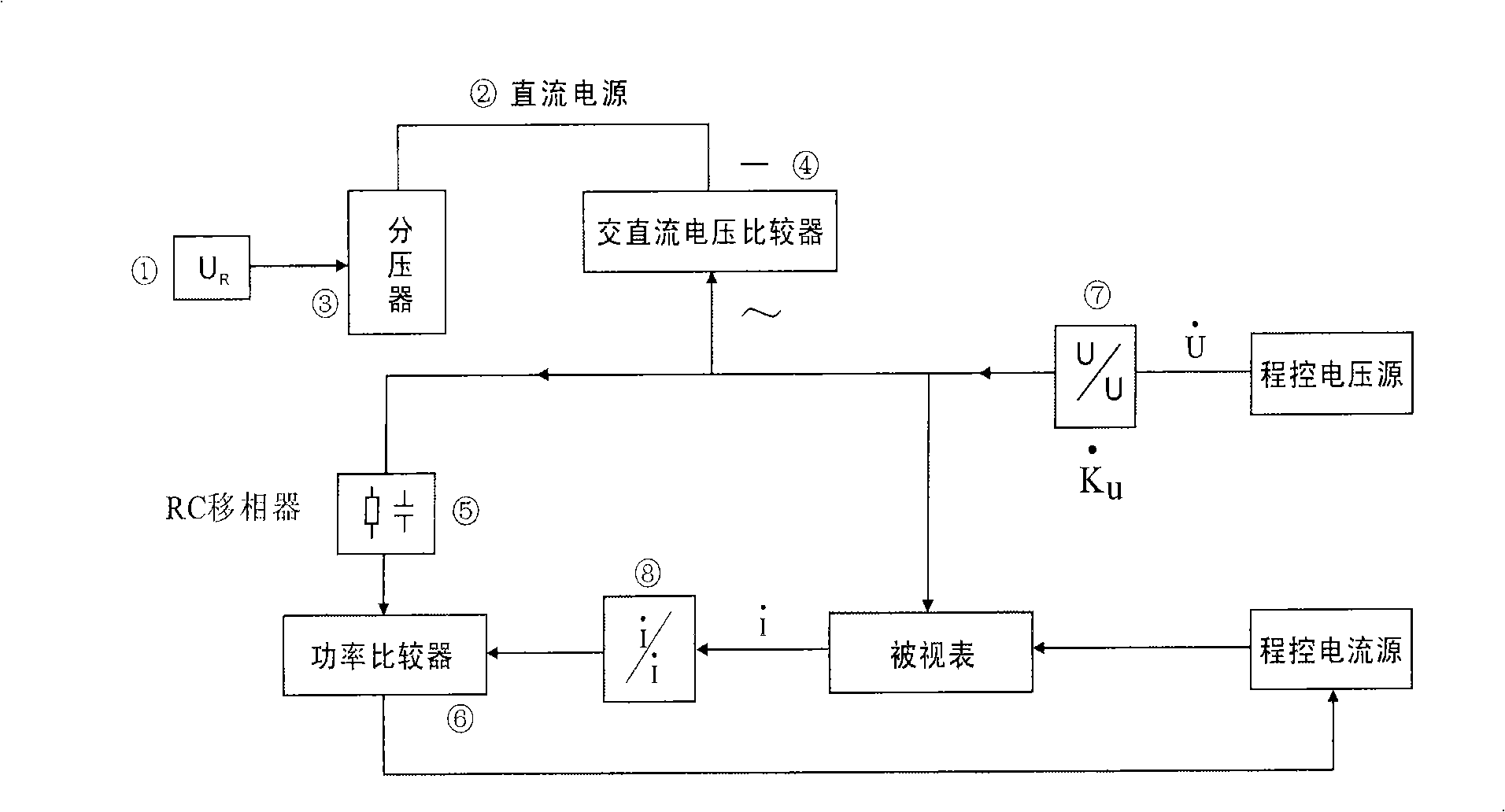

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

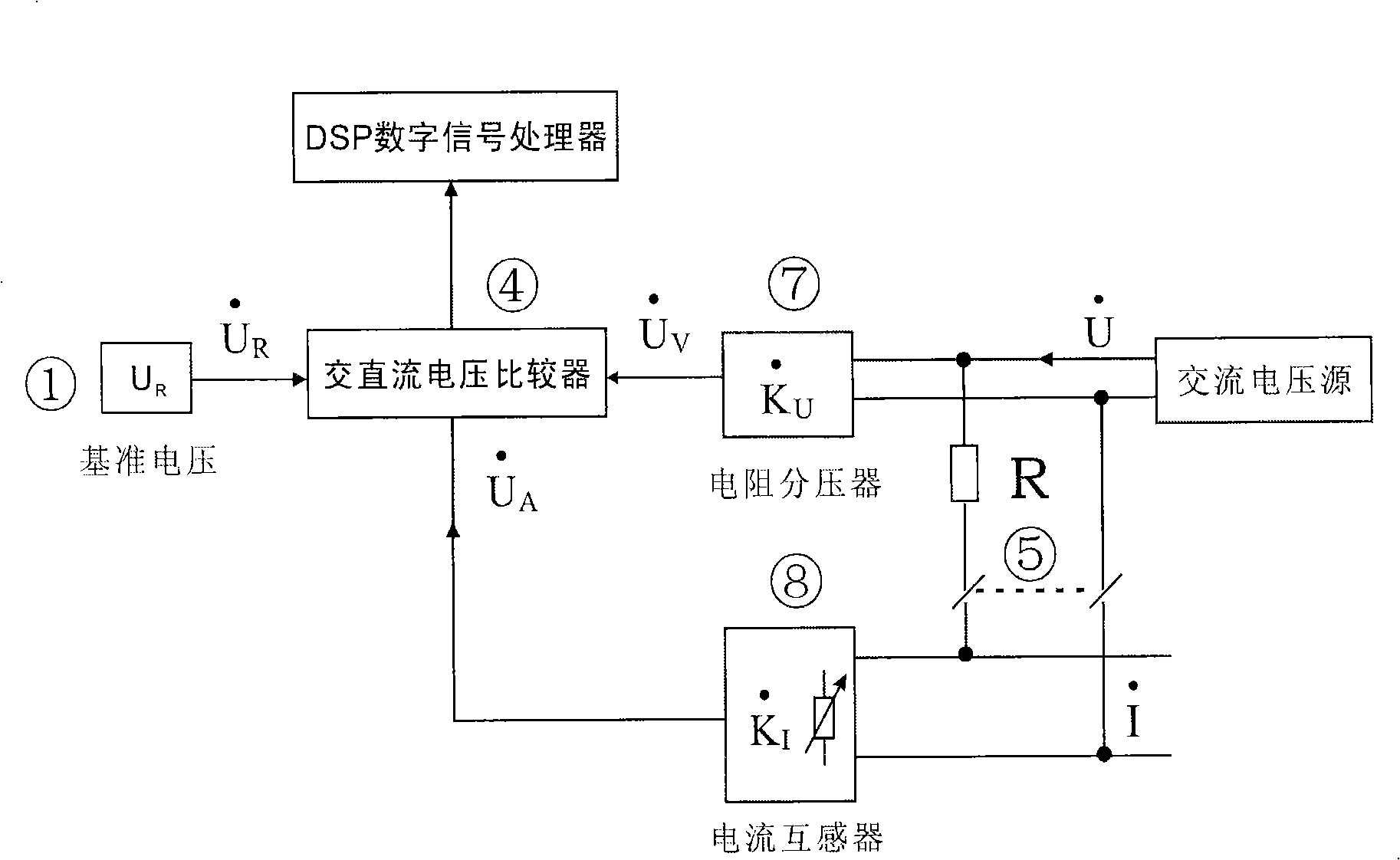

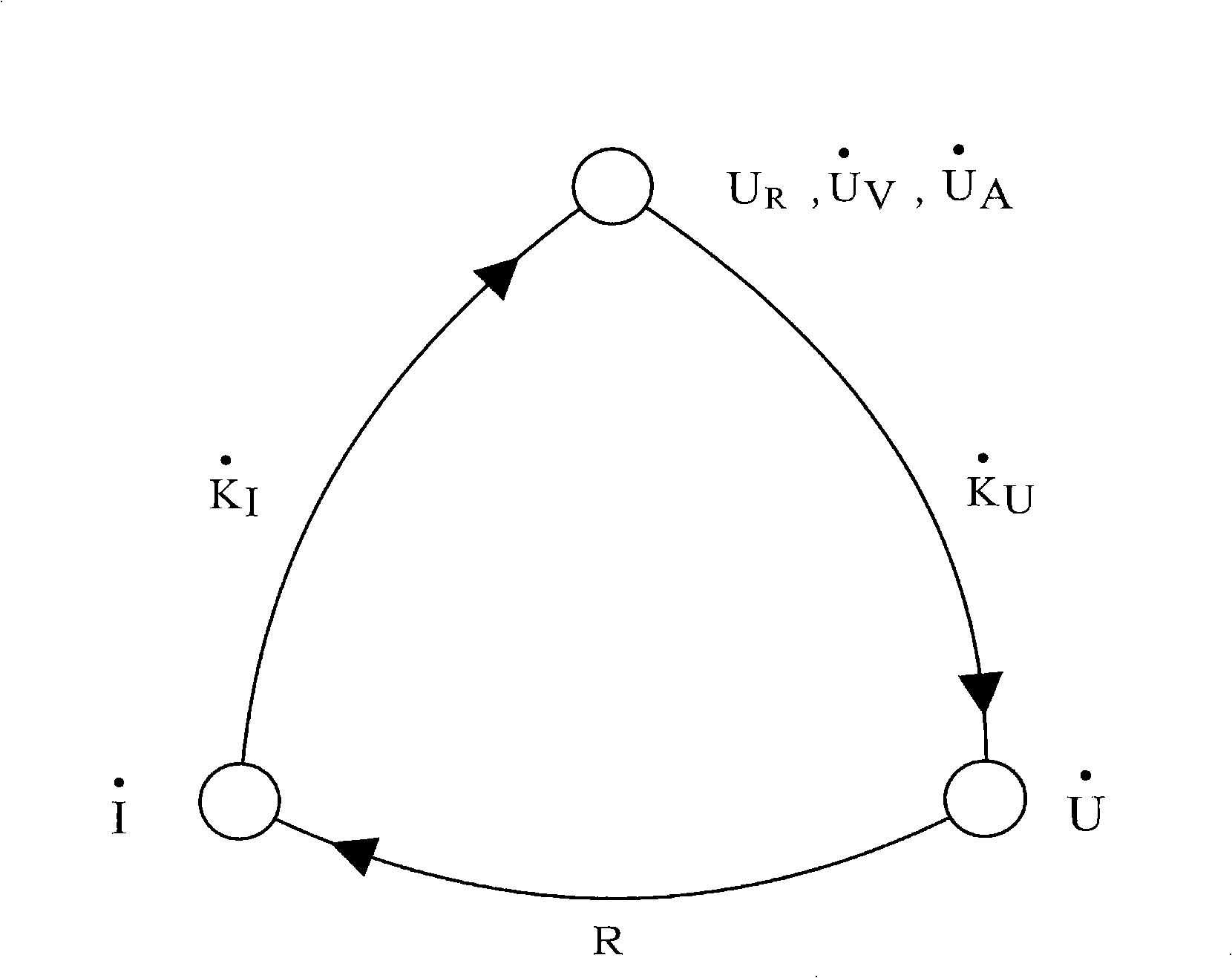

[0027] Such as figure 2 , adopt DC reference voltage source in the inventive method, stable AC voltage source, voltage divider, high-precision resistance, current transformer, the AC-DC voltage comparator and DSP digital signal processor with two-way self-calibration process, wherein The DC reference reference voltage source, stable AC voltage source, high-precision resistors, and AC-DC voltage comparators with self-calibration use standard devices. The high-precision resistors are designed without inductance and capacitance. Zero and span calibration. Standard devices can calibrate or self-test high-precision DC references and high-precision resistors, and can be easily calibrated or compared with existing 8.5-digit digital voltmeters. Voltage divider calibration.

[0028] The AC voltage output high end of the stable AC voltage source is connected to the high end of the voltage divider and one end of the precision resistor at the same time, the other end of the precision r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com