Lens shifting mechanism with shape memory alloy

A memory alloy and lens technology, applied in the field of auto-focus lens modules, can solve problems such as insufficient simplification, unfavorable mass production, and reduced magnetic force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

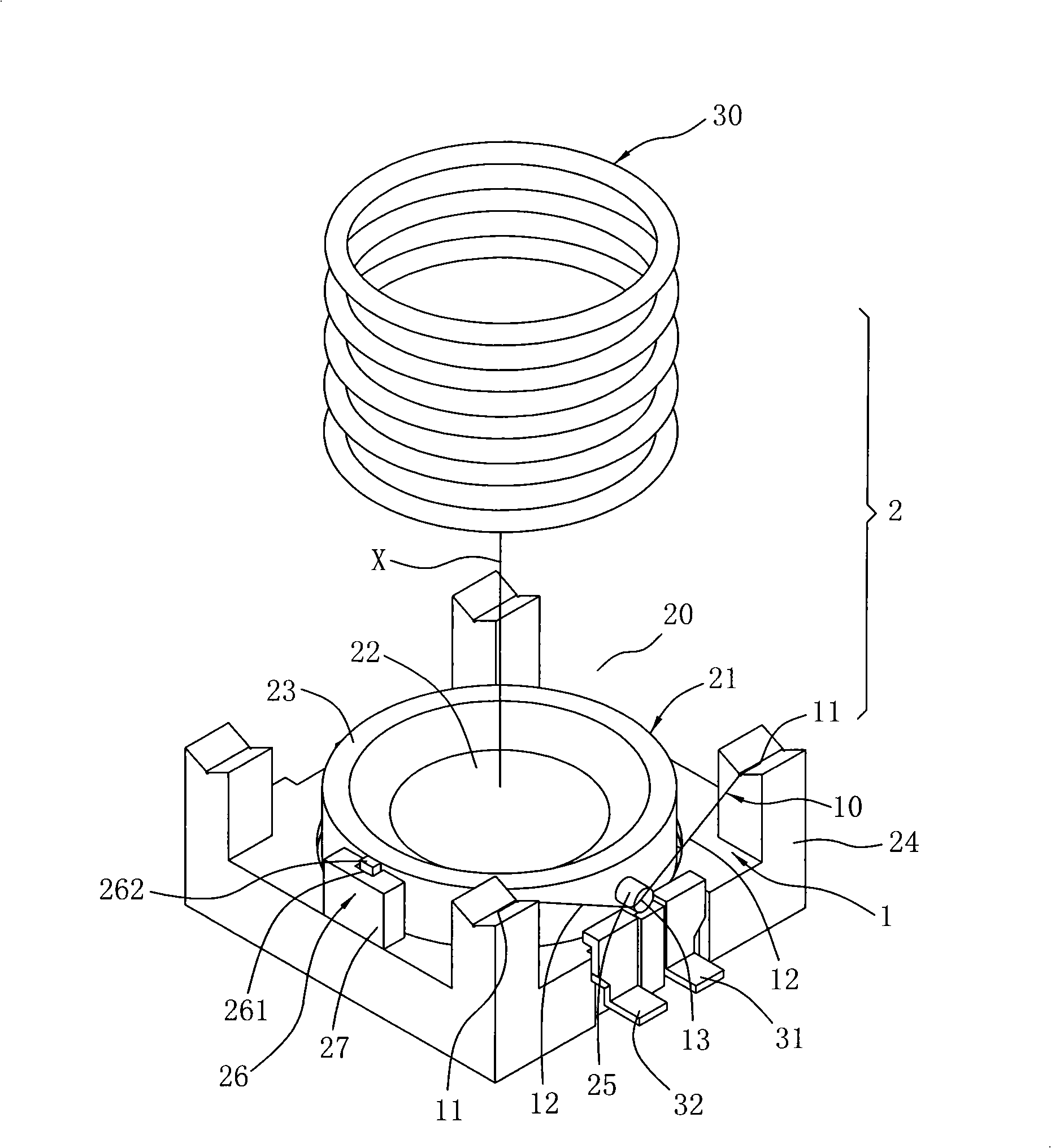

[0025] refer to Figure 1-3 As shown, the present embodiment utilizes an SMA wire 10. When the object distance is from far to near, the lens 21 moves away from the imaging side toward the object side to achieve the purpose of focusing; in this embodiment, the lens 21 and the imaging surface The distance changes are shown in Table 1:

[0026] Table I

[0027] Object distance(mm)

70

100

600

1000

infinity

camera shift

Distance (mm)

0.243

0.167

0.023

0.011

0

[0028] When focusing, the lens 21 is controlled to move, that is, the auto-focus lens 21 is controlled by a focus button (not shown in the figure), when the user presses the focus button, the electrodes 31, 32 can pass When the power is supplied to the lens shifting mechanism 1, when the control current flows through the SMA wire 10, Joule heat (Joule heat) may be generated due to the impedance of the SMA wire 10, causing ...

no. 2 example

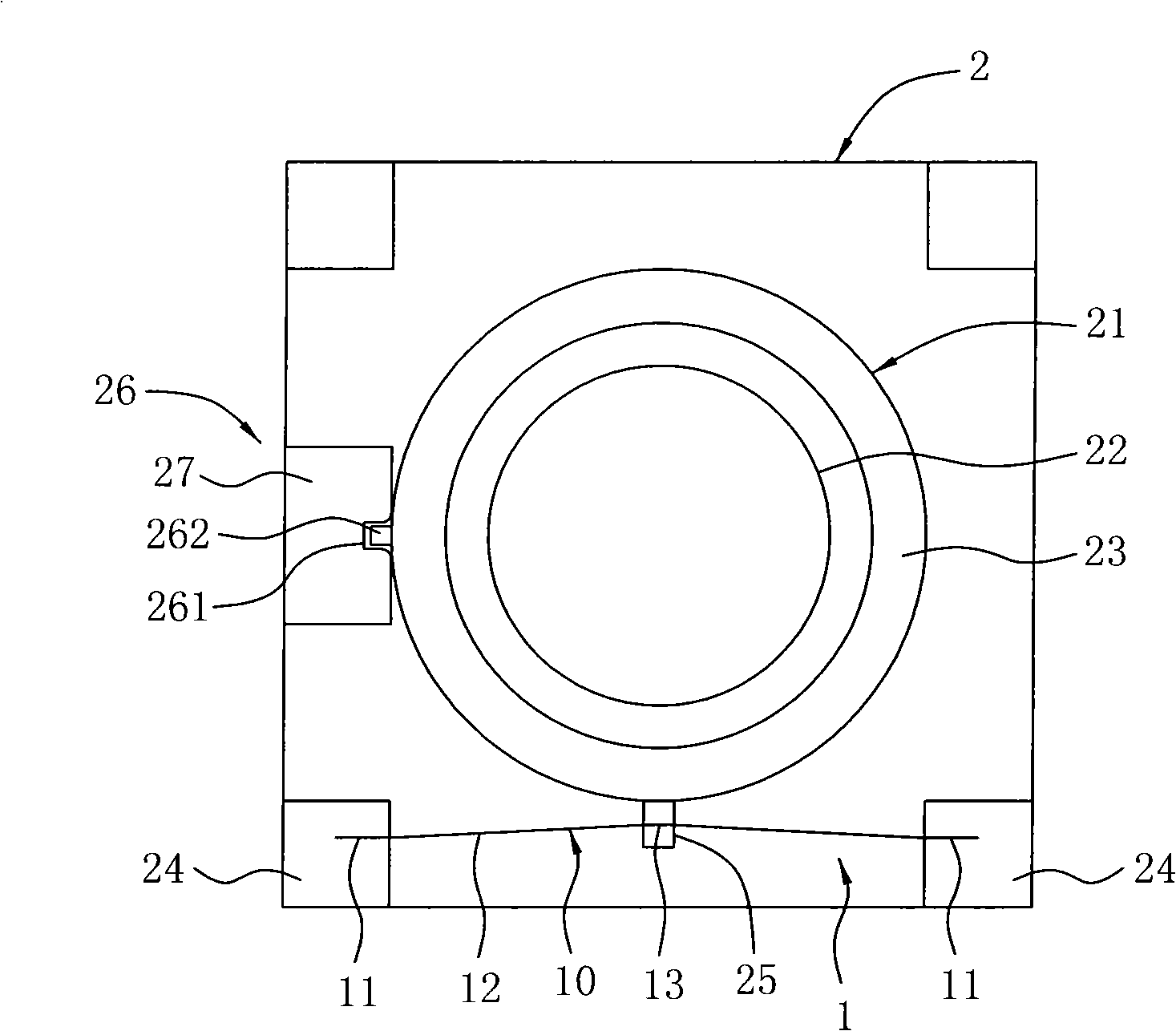

[0036] refer to Figure 4-6 As shown, the present embodiment utilizes two SMA wires 10, and the two SMA wires 10 are arranged at the outer periphery of the lens 21 symmetrically or equidistantly; the two SMA wires 10 of the present embodiment Its two opposite ends 11 are fixed on the two symmetrical sides of the outer edge of the lens 21, and each middle movable section 12 is respectively tensioned and suspended on the symmetrical sides respectively arranged on the outer edge of the lens 21 with its length to the middle point 13. On the hook 25 of each SMA wire 10, the middle movable section 12 of each SMA wire 10 forms a tense state with respect to the two opposite ends 11; through the above structure, when the two SMA wires 10 are heated due to current conduction, the middle of each SMA wire 10 The movable section 12 can be contracted synchronously and pull the corresponding hook 25 on the lens 21 to synchronously drive the lens 21 to slide and shift on the optical axis X to...

no. 3 example

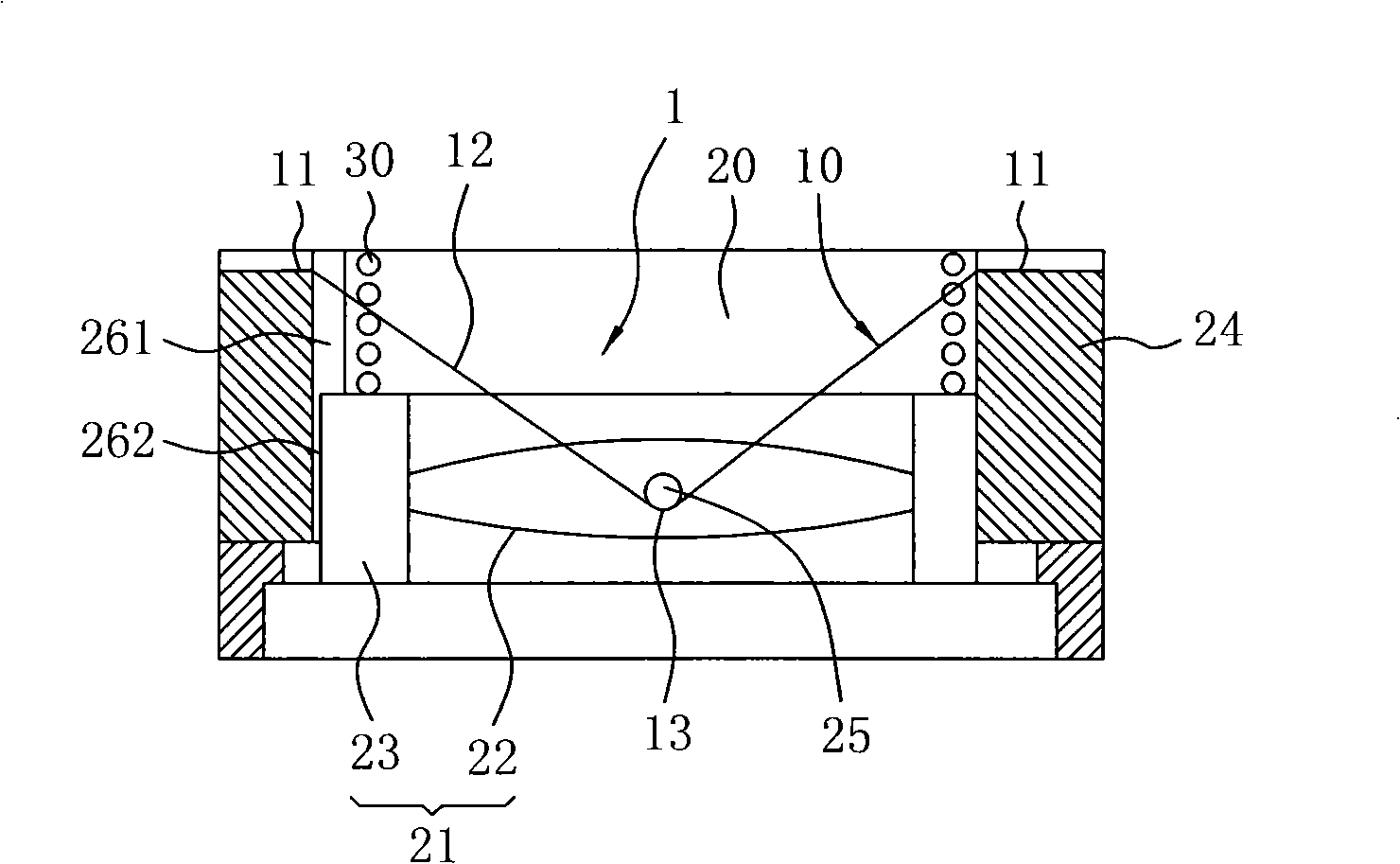

[0042] refer to Figure 7-Figure 9 As shown, the present embodiment utilizes four SMA wires 10, and it is better that the four SMA wires 10 are arranged symmetrically or equidistantly around the outer periphery of the lens 21, that is, the two opposite ends of the four SMA wires 10 11 is respectively fixed on the four opposite sides of the lens 21, so that the middle movable section 12 of each SMA line 10 is respectively tensioned to the middle point 13 by its length and hung on the corresponding hook 25 set up on the opposite side of the outer edge of the lens 21 Above, the middle movable section 12 of each SMA wire 10 forms a tense state relative to the two opposite ends 11; through the above structure, when the four SMA wires 10 are heated due to current conduction, the middle movable section 12 of each SMA wire 10 can be synchronized Shrink and pull the corresponding hook 25 on the lens 21 to synchronously drive the lens 21 to slide and shift on the optical axis X to achie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com