High-performance permanent ferrite and dyadic manufacturing method thereof

A permanent magnet ferrite and production method technology, applied in the direction of magnetism of inorganic materials, can solve the problems of difficult forming of magnetic parts, fine particle size, high price, etc., and achieve the effects of improving market competitiveness, high magnetic performance, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] In order to further describe the present invention, the high-performance permanent magnet ferrite and its binary production method of the present invention will be further described below in conjunction with examples.

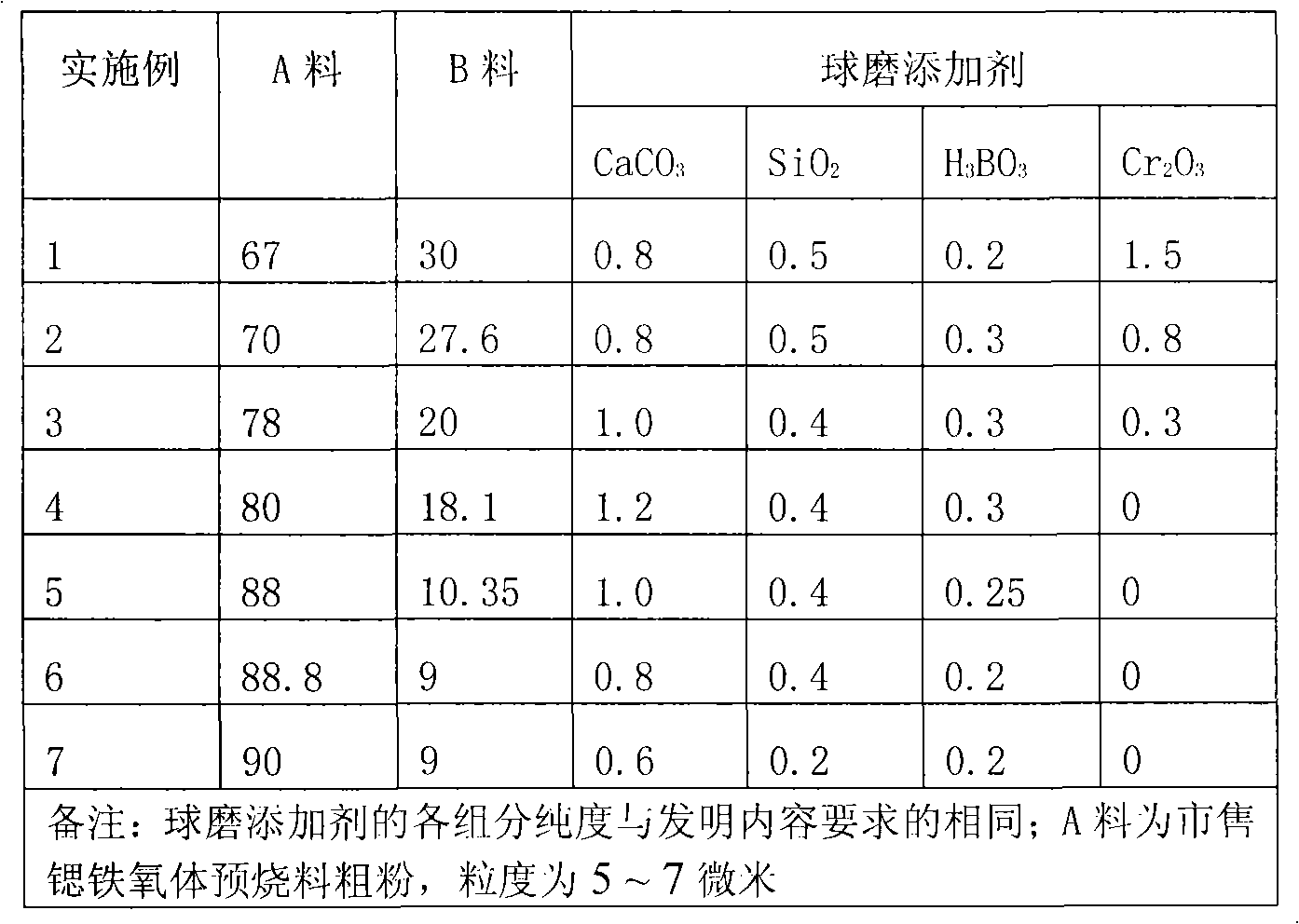

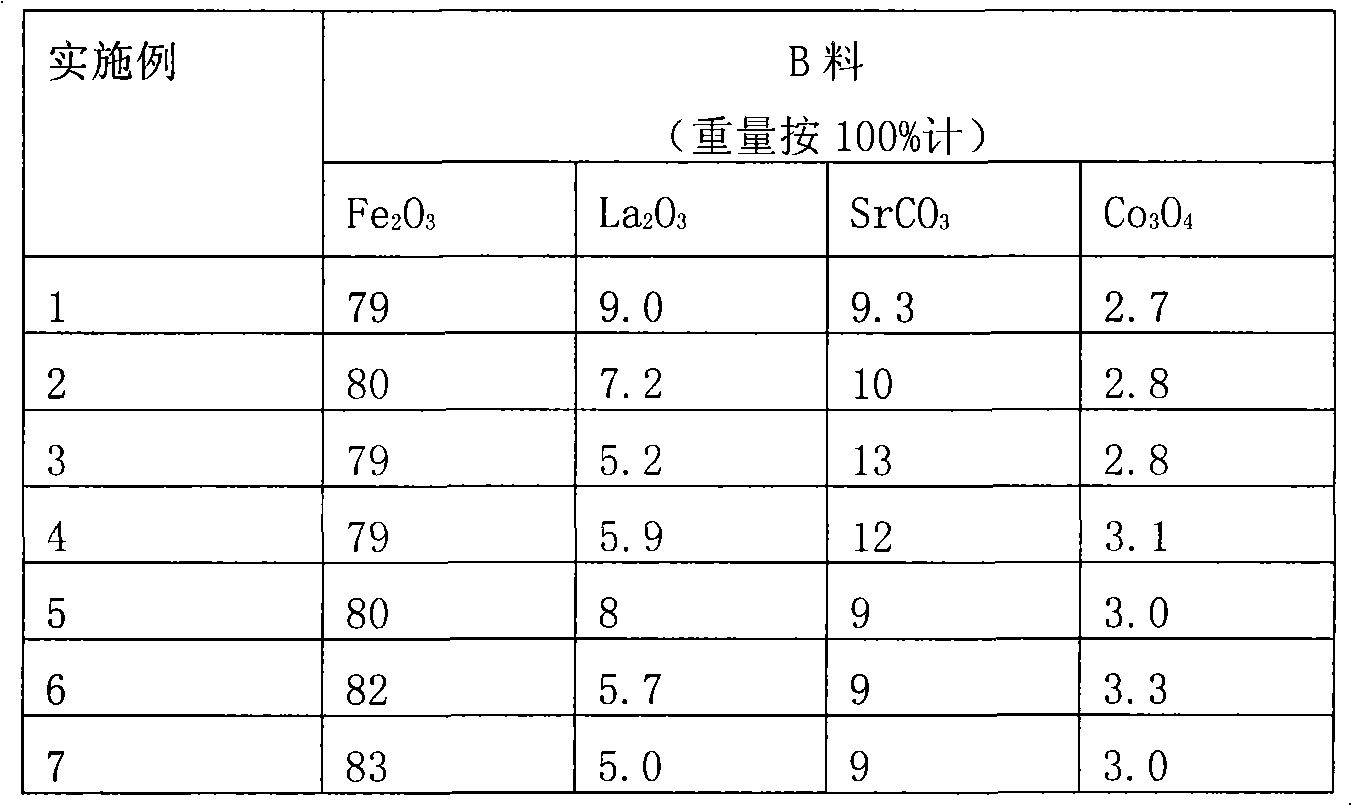

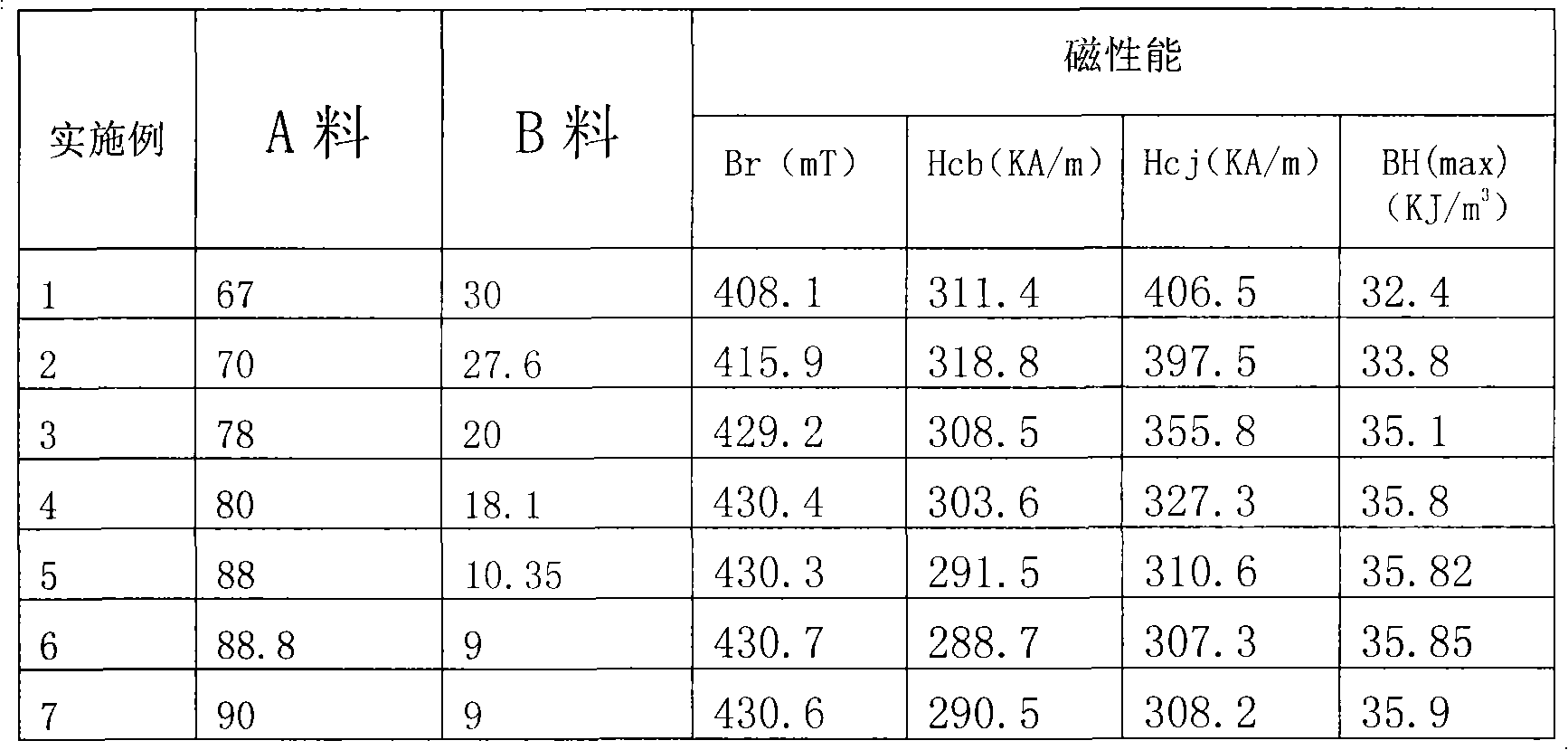

[0060] Table 1 lists the high-performance permanent magnet ferrite examples 1-7 raw material formulations, Table 2 lists the B material formulations of Examples 1-7, and Table 3 lists the magnetic properties of the final product.

[0061] Table 1 High-performance permanent magnet ferrite raw material formula (100%)

[0062]

[0063] The B material formula of table 2 embodiment 1-7

[0064]

[0065] The magnetic property of the final product of table 3 embodiment 1-7

[0066]

[0067] The production steps of embodiment 1-7 are the same as the content of the invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com